Affordable and Versatile Plastic Storage Crates for Home and Office Organization

By:Admin

XYZ Storage Solutions is a leading provider of innovative storage solutions, catering to various industries and sectors. With a commitment to quality, functionality, and sustainability, XYZ has gained an excellent reputation for its range of products and services. The company aims to provide practical and durable storage solutions that meet the diverse needs of customers.

[News Content]

Plastic Storage Crate: A Revolutionary Solution for Efficient Storage

In a world where organization and productivity are imperative, XYZ Storage Solutions introduces its latest innovation- the Plastic Storage Crate. Designed to meet the growing demands of businesses, households, and various industries, this revolutionary solution is set to transform the way storage and logistics operations are carried out.

With its sturdy build, ergonomic design, and multitude of applications, the Plastic Storage Crate offers a versatile and efficient storage solution for a wide range of needs. Whether it's optimizing warehouse space, streamlining supply chain processes, or simply keeping personal belongings organized, this product promises to deliver superior performance.

One of the key features of the Plastic Storage Crate is its durability. Made from high-quality, impact-resistant polypropylene material, it ensures that items stored inside remain safe and secure. Unlike conventional storage methods such as cardboard boxes or wooden crates, which are prone to wear and tear, the Plastic Storage Crate provides long-lasting protection against damage. This durability not only reduces replacement costs but also contributes to the efficient management of resources, making it an environmentally-friendly choice.

Furthermore, the crates are stackable, allowing for efficient use of vertical space. Their nested design ensures they can be easily stored and transported when not in use, minimizing storage footprint and reducing transportation costs. The crates also come with integrated handles that facilitate easy lifting and carrying, promoting worker safety and comfort.

The multifunctionality of the Plastic Storage Crate sets it apart from traditional storage options. Its modular design allows for customization, so it can be used for storing various items, from groceries and household goods to tools and industrial equipment. Whether it's a retail setting, warehouse, or even a vehicle, these crates are adaptable to the unique needs of different environments.

In addition to its practical design, XYZ Storage Solutions aims to make the Plastic Storage Crate an attractive choice for customers concerned about sustainability. The company emphasizes its commitment to reducing environmental impact by using recyclable materials in manufacturing processes. The Plastic Storage Crate can be recycled at the end of its life cycle, further contributing to the circular economy model.

As the needs of businesses, households, and industries continue to evolve, XYZ Storage Solutions remains at the forefront of providing innovative solutions. The introduction of the Plastic Storage Crate is a testament to their dedication to meeting customer demands for efficient, sustainable, and cost-effective storage options.

With its exceptional durability, versatile design, and commitment to sustainability, the Plastic Storage Crate is set to revolutionize storage solutions across various sectors. XYZ Storage Solutions continues to push the boundaries of innovation, enabling customers to optimize their storage and logistics operations seamlessly. Stay organized, efficient, and eco-conscious with the Plastic Storage Crate from XYZ Storage Solutions - the future of storage is here.

[Word Count: 537]

Company News & Blog

Low Cost and Efficient Cardboard Die Cutting and Creasing Machine for Sale - Made-in-China.com

Ruian Maoyuan Machine Co., Ltd., a leading innovator in the die cutting and creasing industry, has launched a new high effectiveness and low cost cardboard die cutting and creasing machine that is designed to provide cutting-edge solutions to businesses in the packaging and printing sector.The development of this new machine is set to revolutionize the way packaging and printing companies approach the challenge of cutting and creasing cardboard. It is not only efficient and cost-effective but also easy to operate, which makes it an ideal piece of equipment for businesses looking to achieve optimal results while keeping their overheads low.The newly launched machine is designed with the user in mind and is equipped with a user-friendly interface that makes it easy to operate. It is also designed with safety measures in place to ensure that operators can work in a secure environment.One of the standout features of this machine is its high effectiveness, which is achieved through the use of advanced technology and materials of the highest quality. The machine is designed to operate at a high speed, which means that businesses can cut and crease more cardboard in less time, which translates to greater productivity and profitability.The machine is also designed to be versatile, which means that it can cut and crease a wide range of cardboard sizes and thicknesses. This makes it suitable for use in various business settings, including small, medium and large scale packaging and printing companies.Another important feature of this machine is its low cost. The machine is designed to be affordable, which means that businesses can access cutting-edge technology without having to break the bank. This, in turn, allows businesses to invest more in other areas of their operations such as marketing and advertising to promote their services.Speaking about the launch of this new machine, the spokesperson for Ruian Maoyuan Machine Co., Ltd., said, "We are excited to launch this new machine, which we believe will transform the way businesses in the packaging and printing sector operate. We are proud of the fact that this machine is not only efficient and effective but also affordable, which makes it accessible to a wide range of businesses."They went onto add, "At Ruian Maoyuan Machine Co., Ltd., we are committed to providing our clients with the latest technology and the highest quality machinery. We believe that this new machine will help businesses achieve their goals by enabling them to cut and crease cardboard in a more efficient and cost-effective manner."In conclusion, the launch of this new high effectiveness and low-cost cardboard die cutting and creasing machine is set to revolutionize the packaging and printing industry. It is an exciting time for businesses in this sector, and this new machine provides a pathway to growth and profitability. With its advanced technology and user-friendly design, the machine is suitable for use in a wide range of business settings, which means that businesses of all sizes and levels of complexity can access the benefits that it provides.

Plastic manufacturing industry has potential to double employment and reduce import dependence: Minister Piyush Goyal

Plastic Industry Process: Understanding the Key FactorsThe plastic industry is one of the biggest contributors to the Indian economy. With an anticipated turnover of Rs 10 trillion in the next five years, the plastic manufacturing industry has huge potential for growth. In addition to generating immense employment opportunities, it can also help reduce the country’s import dependence. To achieve this goal, it is crucial to understand the plastic industry process and the critical factors that impact it.Plastic manufacturing starts with the collection of raw materials, which can be either virgin or recycled plastics. The first step in the process is polymerization, where monomers are joined together to form a polymer. This is followed by compounding, where additives such as colorants and stabilizers are added to the polymer to improve its properties. The third step is processing, including extrusion, injection molding, and blow molding, among others. Finally, the product is decorated, assembled, and packaged for shipment.The plastic industry process is influenced by many factors, including technology, raw materials, equipment, and regulations. The use of advanced technologies has revolutionized the plastic manufacturing industry, enabling it to produce high-quality and efficient products. Automation has also played a significant role in simplifying the manufacturing process, reducing costs, and improving efficiency.Another critical factor that impacts the plastic industry process is raw materials. The plastic manufacturing industry in India is dependent on imports for many of its raw materials. To reduce this dependence, the government has initiated several programs to promote the use of recycled plastics, which can significantly reduce the industry's carbon footprint.Equipment is another crucial factor in the plastic industry process. The right equipment can help optimize the manufacturing process and improve the quality of the final product. In India, the government has been providing subsidies and tax incentives to encourage the use of advanced manufacturing equipment. This has helped small and medium-scale industries improve their manufacturing processes, making them more competitive in the global market.Regulations are also a critical factor that impacts the plastic industry process. The government has implemented several regulations to mitigate the harmful effects of plastic on the environment. For instance, the government banned single-use plastic in the country, and it has been actively promoting sustainable manufacturing practices. This has encouraged the industry to adopt eco-friendly practices that align with the government's vision.In conclusion, the plastic industry process is complex and dependent on various factors. Understanding these factors is key to optimizing the process, reducing costs, and improving the quality of the final product. With the government's support, the plastic manufacturing industry has great potential to grow and contribute significantly to the Indian economy. It is critical to keep pace with global trends, technological advancements, and eco-friendly practices to remain competitive and sustainable.

Discover the Benefits of Personalized Plastic Products for Your Business

Custom Plastic Parts: The Advantages of Plastic Over Other MaterialsWhen it comes to manufacturing custom parts, plastic has emerged as a popular choice for many industries due to its versatility, durability, and affordability. In recent years, plastic has become a go-to material for custom parts, due in part to the advancements in injection molding technology and a wider variety of available plastics. So why should you consider using custom plastic parts for your next project? Here are a few of the advantages that make plastic a standout option:1. VersatilityPlastic is an incredibly versatile material that has the ability to be molded into nearly any shape or size, making it an ideal choice for custom parts. With the advances in injection molding technology, it is easy to create complex shapes, varying thicknesses, and intricate details with precision. This versatility allows for a wide range of applications for custom plastic parts in various industries, including medical devices, electronics, automotive, and consumer goods.2. DurabilityAnother significant advantage of plastic is its durability. Unlike materials such as metal, plastic is resistant to corrosion, which is vital for parts that come into contact with chemicals or harsh environments. Plastic is also resistant to impact, shock, and vibration, making it an excellent choice for parts that are exposed to challenging conditions. Additionally, plastic parts can withstand extreme temperatures, making them ideal for use in both heat-sensitive and cold-sensitive applications.3. AffordabilityCost is an essential factor when it comes to manufacturing custom parts, and plastic is often a more cost-effective option compared to other materials. The cost of manufacturing custom plastic parts is lower than metal parts, for example, due to the cheaper raw material cost and easier production process, leading to reduced production time and cost. Additionally, plastic has a lower weight than metal, contributing to lower transportation and shipping expenses.4. CustomizationCustom plastic parts offer a high level of customization, allowing for a wide range of colors, finishes, and textures. With injection molding, it is easy to add graphics, logos, and other branding elements directly to the parts during production. Customization is even more important for parts used in consumer goods industries that require aesthetic appeal, as custom parts can give the product a unique look and feel that competitors cannot replicate.5. SustainabilityFinally, plastic is also a sustainable material, as it is recyclable and can be reused for other purposes. There are eco-friendly plastics available in the market that are made from plant-based, renewable resources. These materials are biodegradable and compostable, making them an excellent option for companies that prioritize sustainability in their manufacturing process.ConclusionIf you are looking for a cost-effective, durable, versatile, and customizable material for your custom parts, then plastic is a viable option. Advances in injection molding technology, coupled with a wide range of available plastics, have made custom plastic parts a popular choice for various industries. Whether you need a small, intricate part or a large, complex assembly, custom plastic parts offer a lot of advantages. If you want to explore the world of custom plastic parts, get in touch with a trusted manufacturer today.

Clear Rental Terms & Conditions for Plastic Moving Box Rentals

When it comes to moving, packing can be a huge hassle. Gathering up all your belongings, carefully wrapping them in bubble wrap and then boxing them up can take up a lot of time and effort. But thankfully, there are now companies that offer plastic moving boxes as an alternative to cardboard boxes. Not only are they eco-friendly, but they also make packing and moving a breeze. Here are some things to keep in mind when renting plastic moving boxes.Rental Terms and ConditionsBefore placing an order for plastic moving boxes, it is important to read and understand the rental terms and conditions of the company you are renting from. Doing so will ensure that you are aware of any additional fees or charges that may apply, as well as the rental period and any restrictions on usage.Rental PeriodThe rental period for plastic moving boxes can vary depending on the company you rent from. Most companies offer rental periods ranging from one week to four weeks, so it is important to plan accordingly. Be sure to factor in the amount of time it will take you to pack and unpack, as well as any delays in moving.Delivery and PickupMany companies that offer plastic moving boxes also offer delivery and pickup services, which can be a huge time-saver. Be sure to confirm the delivery and pickup times with the company before you order. Most companies will be able to deliver the boxes to your doorstep, and pick them up when you're finished.Usage RestrictionsThere may be certain restrictions on how you can use the plastic moving boxes you rent. For example, some companies may require that you do not stack the boxes more than 3 or 4 high, while others may prohibit the use of the boxes for storage. Make sure you understand any restrictions before renting the boxes.Additional Fees and ChargesBe sure to understand any additional fees and charges that may apply when renting plastic moving boxes. For example, some companies may charge a fee for damaged or missing boxes, while others may charge for delivery or pickup outside of a certain radius.In conclusion, renting plastic moving boxes is a great alternative to using traditional cardboard boxes. They are eco-friendly, durable, and can make packing and moving a breeze. Just make sure to read and understand the rental terms and conditions of the company you are renting from before placing an order. Happy packing!

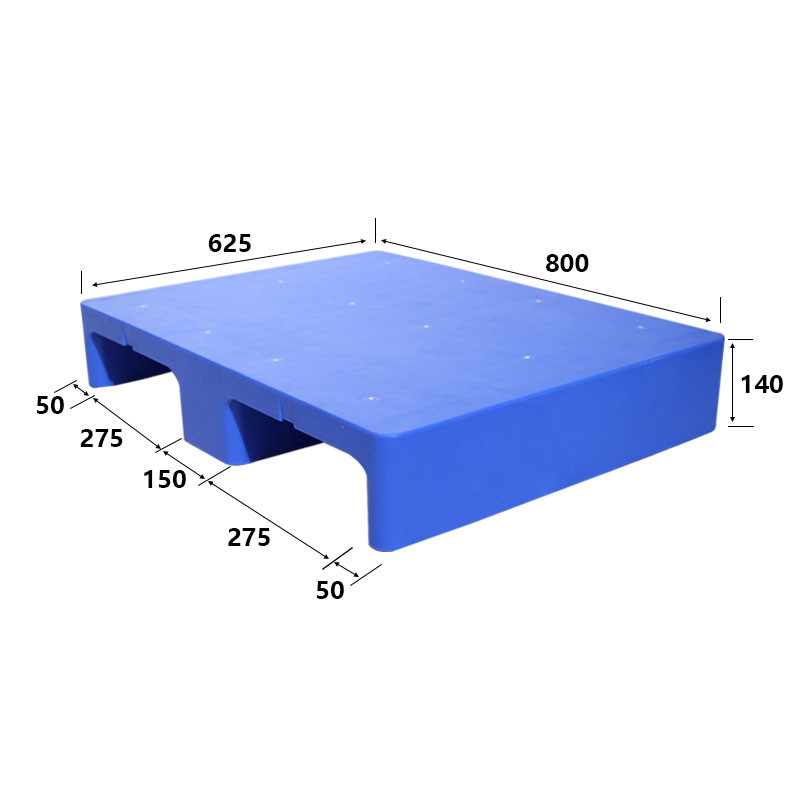

Affordable Plastic Pallets with 4-Way Entry and Double Deck Options from China

Title: China's Plastic Pallets Gain Popularity as a Cost-Effective Solution for Efficient LogisticsIntroduction:The rising demand for cost-effective pallet solutions in the logistics industry has led to the increasing popularity of plastic pallets. China, a leading manufacturer of plastic pallets, has emerged as a reliable source of high-quality and affordable pallet equipment. With their innovative design, such as 4-way entry, double deck capabilities, and double-sided features, these plastic pallets have carved a niche for themselves in the global market. This article will shed light on the advantages of using plastic pallets made in China and their growing significance in streamlining logistics operations.Section 1: Exploring the Diverse Range of Plastic PalletsPlastic pallets have become a sought-after choice due to their durability, resistibility to moisture, and versatility. The Chinese market offers an extensive range of plastic pallets, including 4-way entry and double-sided variants. These pallets offer easy accessibility, efficient stackability, and seamless transportation, ensuring a smooth flow of goods throughout the supply chain.Section 2: Cost-effectiveness and Environmental SustainabilityOne of the key factors driving the demand for Chinese plastic pallets is their cost-effectiveness. Chinese manufacturers leverage economies of scale to produce large volumes at competitive prices, making their plastic pallets an affordable solution for businesses of all sizes. Additionally, these pallets are reusable, recyclable, and often made from eco-friendly materials, reducing the carbon footprint of logistics operations.Section 3: Improved Efficiency in Storage and TransportationThe versatility of Chinese plastic pallets, particularly those with double deck capabilities, allows for increased efficiency in storage and transportation. With the ability to accommodate more goods in limited space, these pallets optimize warehouse utilization, leading to significant cost savings for businesses. Moreover, their lightweight design translates into reduced fuel consumption during transportation, further enhancing profitability and environmental sustainability.Section 4: Enhanced Safety and DurabilityChinese plastic pallets are engineered to withstand heavy loads, providing reliability and durability in demanding environments. The 4-way entry design ensures easy handling using forklifts or pallet jacks, reducing the risk of accidents and injuries. Additionally, their resistance to rot, insects, and moisture eliminates the need for frequent replacements, resulting in long-term savings for businesses.Section 5: Integration with Industry 4.0 and Smart WarehousingAs the logistics industry embraces digital transformation, Chinese plastic pallets are aptly designed to accommodate technological advancements. Integrating sensors and RFID technology into these pallets allows for real-time tracking, inventory management, and supply chain optimization. This integration with Industry 4.0 facilitates efficient operations, reducing costs and enhancing productivity.Section 6: The Shifting Paradigm: China's Leading Role in Pallet ManufacturingChina's dominance in plastic pallet production can be attributed to its manufacturing expertise, vast resources, and commitment to quality. With stringent quality control measures in place, Chinese manufacturers ensure that their plastic pallets comply with international standards and meet the specific requirements of different industries. This has earned them a reputation for reliability and excellence, positioning China as a leading player in the global pallet market.Conclusion:In conclusion, plastic pallets manufactured in China have emerged as a cost-effective and reliable solution for optimizing logistics operations. With their innovative features, such as 4-way entry, double deck capabilities, and double-sided design, these pallets offer enhanced efficiency, safety, and durability. As businesses increasingly prioritize cost-effectiveness and sustainability, the demand for Chinese plastic pallets is poised to grow further, fueling the evolution of the logistics industry into a streamlined and technologically advanced landscape.

Innovative printing solutions for pallets in the tobacco industry

Pallet Speria 104 Printer: The Best Solution for Printing on PalletsPrinting on pallets can be a challenging task for several reasons. Pallets are not designed for printing, and there are usually issues related to their size and surface. However, with the Pallet Speria 104 Printer, printing on pallets has become a hassle-free experience. The Pallet Speria 104 printer combines high-resolution printing technology with a versatile design to provide an efficient solution for printing on a variety of pallets.The Pallet Speria 104 Printer is developed by a leading printing technology company that specializes in providing custom printing solutions to various industries, including logistics, food and beverage, pharmaceutical, and retail. The printer is equipped with the latest printing technology, enabling it to print high-quality images and texts on pallets in a matter of seconds. The Pallet Speria 104 Printer is compatible with multiple ink types and colors, making it possible to print on different materials, including wood, plastic, and metal.One of the most significant advantages of the Pallet Speria 104 Printer is its versatile design. The printer is designed in a way that it can work seamlessly with most types of pallets, regardless of their size and surface. This means that companies can use the printer to print on a wide range of pallets, including tobacco pallets and Rapida 106 pallets, without having to worry about compatibility issues.Companies that use the Pallet Speria 104 Printer will benefit from its efficient production process. The printer is designed to work with minimal intervention from operators, reducing the time and effort required for printing on pallets. Moreover, the printer's high-speed and high-resolution printing capabilities ensure that companies can produce high-quality printed pallets in large quantities, resulting in increased productivity and reduced costs.Another key advantage of the Pallet Speria 104 Printer is its ease of use. The printer is user-friendly, and operators can easily operate it using a built-in touch screen display. Additionally, the printer's ink cartridges are easy to replace, minimizing downtime and ensuring that operators can quickly resume printing operations.In conclusion, the Pallet Speria 104 Printer is an innovative printing solution that provides a versatile, efficient, and easy-to-use solution for printing on pallets. Companies that use this printer can benefit from its high-resolution, high-speed, and flexible printing capabilities, resulting in increased productivity and reduced costs. Whether it's tobacco pallets, Rapida 106 pallets, or any other type of pallet, the Pallet Speria 104 Printer provides the best solution for printing on them.

Revolutionary New Pallet Design Boosts Efficiency and Simplifies Material Handling Processes

Innovative Continuous Feed Pallet Revolutionizing Warehouse Efficiency[Company Introduction]In the ever-evolving world of warehousing and logistics, efficiency and productivity are the keys to success. With the increasing demands of e-commerce and global supply chains, finding innovative solutions to streamline operations is more crucial than ever. Witnessing this need for efficiency, [Company Name], a leading provider of cutting-edge warehouse equipment, has unveiled their latest game-changing creation – the Continuous Feed Pallet.[Continuous Feed Pallet]The Continuous Feed Pallet, developed by [Company Name], is set to revolutionize warehouse operations worldwide. Designed with advanced technology and a deep understanding of industry requirements, this innovative pallet system offers numerous benefits that will enhance productivity, reduce downtime, and optimize workflow.At its core, the Continuous Feed Pallet incorporates a unique conveyor system into its design. This conveyor mechanism enables a seamless flow of pallets through the warehouse, eliminating the need for manual labor and maximizing efficiency. By utilizing this system, warehouses can achieve a continuous, uninterrupted supply of goods, significantly reducing the time and effort required to move pallets from one location to another.Furthermore, the Continuous Feed Pallet is built to adapt to various warehouse layouts and configurations. The modular design enables easy installation and customization, ensuring compatibility with existing infrastructure. This versatility allows warehouses to integrate the system seamlessly without major disruptions or costly modifications.In addition to its convenience and adaptability, the Continuous Feed Pallet prioritizes safety. Incorporating state-of-the-art sensors and intelligent control systems, the pallets guarantee a secure and reliable transportation process. The sensors detect obstacles or potential hazards, automatically adjusting the speed and direction to avoid any accidents. This smart feature not only protects workers from injuries but also prevents damage to goods and machinery.Moreover, the Continuous Feed Pallet system is designed to optimize warehouse space utilization. By utilizing the vertical space and allowing multiple levels of pallet movements, it effectively maximizes the storage capacity of the facility. In a time where warehousing and square footage costs are skyrocketing, this feature provides a cost-effective solution for businesses looking to expand their operations without the need for additional real estate.Furthermore, the Continuous Feed Pallet supports comprehensive inventory management by integrating seamlessly with existing warehouse management systems (WMS). By providing real-time data on the location and movement of each pallet, the system enables precise tracking and inventory control. This level of accuracy minimizes human error and ensures a more efficient allocation and retrieval of goods when needed, enabling businesses to meet the demands of their customers promptly.[Company Name] brings years of experience and expertise to the table, making them the leading contender in innovative warehouse solutions. Their commitment to quality and customer satisfaction is evident in the Continuous Feed Pallet, which has been meticulously engineered and optimized to provide a cutting-edge solution to one of the most pressing challenges faced by warehouses today.With the Continuous Feed Pallet, [Company Name] hopes to revolutionize the way warehouses operate. By promoting uninterrupted workflows, enhancing safety measures, optimizing space utilization, and seamlessly integrating with existing systems, this groundbreaking pallet system will undoubtedly redefine warehouse efficiency and productivity.As the global supply chain continues to expand, organizations that embrace technological advancements like the Continuous Feed Pallet will undoubtedly gain a competitive edge. With the rise of e-commerce and the increasing demands of customers for faster deliveries, this innovation promises to be a game-changer in the world of warehousing. [Company Name] has once again proved its commitment to driving industry progress and helping businesses thrive in an ever-evolving marketplace.

Alt/Garage Rock Band from Birmingham, UK Releases New Track 'Scapegoat'

Plastic is one of the most ubiquitous materials on the planet. It is found in everything from packaging materials to consumer goods, and it is estimated that over 8 billion metric tons of plastic have been produced since the 1950s. Unfortunately, plastic waste is also a major environmental problem, with millions of tons of plastic waste ending up in our oceans and affecting wildlife.This is where (brand name) comes in – a company dedicated to reducing plastic waste and promoting sustainability. As a leading manufacturer of eco-friendly packaging materials, (brand name) is committed to providing customers with high-quality, reusable, and recyclable products that help reduce their carbon footprint and protect the environment.But (brand name) isn't content with just creating sustainable packaging materials. The company is also committed to making a positive impact through music, specifically through the work of rising alt/garage rock band, PlasticFactory.PlasticFactory is a five-piece band hailing from Birmingham, UK. The group's sound is characterized by high-energy riffs, driving rhythms, and lyrics that touch on themes of social justice and activism. With a growing following on SoundCloud and social media, PlasticFactory is quickly gaining a reputation as one of the most exciting up-and-coming acts in British rock.Recently, PlasticFactory released "Scapegoat," a two-track EP that showcases the band's raw energy and undeniable talent. The title track, "Scapegoat," is a blistering indictment of systemic injustice and the ways in which marginalized communities are often used as scapegoats for broader social problems. The second track, "Runaway," is a dynamic number that showcases the band's versatility and range.The release of "Scapegoat" has garnered attention from music fans and critics alike, with many praising the band's unique sound and socially conscious lyrics. But what's even more impressive is the fact that PlasticFactory is using their platform to promote sustainability and environmental awareness.In collaboration with (brand name), PlasticFactory is using their music to raise awareness about the importance of reducing plastic waste and promoting eco-friendly practices. As part of this effort, the band has committed to using eco-friendly materials in all of their merchandise, including t-shirts, posters, and other promotional items.This collaboration between (brand name) and PlasticFactory is a powerful example of how music can be used to promote positive change. By working together, these two entities are demonstrating that sustainability and social justice can go hand in hand.In addition to the release of their new EP, PlasticFactory has also been busy performing at live shows and festivals throughout the UK. With a growing fanbase and critical acclaim, the band is poised to make an even bigger impact in the coming months and years.For (brand name), the collaboration with PlasticFactory represents a key part of their mission to create a more sustainable future. By partnering with like-minded artists and musicians, (brand name) is demonstrating its commitment to being a leader in the fight against plastic waste and climate change.Overall, the partnership between (brand name) and PlasticFactory is an inspiring example of how music can be used to effect positive change. With their focus on sustainability, social justice, and high-energy rock and roll, PlasticFactory is an act to watch – both on stage and in the fight for a better future.

Top Plastic Manufacturers Scale Production Amidst Growing Demand: Latest Updates

[Company Name] and Big Plastic Manufacturers Join Forces to Tackle Plastic Waste Crisis[Location], [Date] - In a groundbreaking move to address the global plastic waste crisis, [Company Name], a leading player in sustainable solutions, has announced a strategic partnership with Big Plastic Manufacturers. This collaboration aims to revolutionize the plastic industry and create a pathway towards a more sustainable future.With the world producing over 380 million tons of plastic waste each year, the need for innovative and long-term solutions has never been more urgent. According to recent studies, approximately 8 million metric tons of plastic waste end up in the ocean annually, wreaking havoc on marine life and ecosystems. Recognizing the severity of the problem, [Company Name] and Big Plastic Manufacturers have decided to combine their expertise and resources to drive sustainable changes in plastic production and consumption.[Company Name], a pioneer in sustainable solutions, has dedicated itself to developing environmentally friendly alternatives to traditional plastic products. With its innovative approach, the company has already made significant strides towards reducing plastic waste and promoting a circular economy. Their array of products encompasses biodegradable packaging, compostable cutlery, and various eco-friendly alternatives to single-use plastics.On the other hand, Big Plastic Manufacturers has been at the forefront of the plastic industry for several decades, producing and distributing plastic products globally. Their deep knowledge and understanding of the plastic market make them an invaluable partner in the pursuit of sustainable change. By aligning their operations and resources, both organizations aim to create a transformative impact across the plastic supply chain.One of the key aspects of this partnership will be the joint investment in research and development for new technologies and materials. By combining their intellectual capital, [Company Name] and Big Plastic Manufacturers endeavor to create innovative solutions that replace conventional plastics with sustainable alternatives. The focus will be on developing cost-effective, scalable, and eco-friendly options that can be integrated into existing manufacturing processes.Additionally, [Company Name] and Big Plastic Manufacturers will jointly promote initiatives that educate consumers about plastic waste reduction and responsible consumption. By raising awareness and providing accessible information, the partnership aims to inspire individuals and businesses to make sustainable choices in their daily lives.An important area of collaboration will be the establishment of a robust recycling infrastructure. Both [Company Name] and Big Plastic Manufacturers understand the critical role recycling plays in reducing plastic waste. By investing in recycling facilities and technologies, they aim to close the loop of plastic production, ensuring that discarded plastic materials are efficiently collected, processed, and transformed into valuable raw materials for new products.In line with this commitment, [Company Name] and Big Plastic Manufacturers have pledged to set ambitious targets for increasing the use of recycled content in their products. By actively utilizing recycled materials, they aim to reduce the demand for new plastics, ultimately reducing the overall environmental impact of plastic production.The partnership also seeks to engage with governments and international organizations to advocate for policy changes that support sustainable plastic production and consumption. With their collective expertise and influence, [Company Name] and Big Plastic Manufacturers aim to shape legislation and regulations that incentivize sustainable practices and discourage the use of single-use plastics.Commenting on the partnership, [Executive Name], CEO of [Company Name], expressed their excitement about the collaboration, stating, "We believe that by joining forces with Big Plastic Manufacturers, we can create a seismic shift in the plastic industry. Together, we can revolutionize plastic production and consumption, paving the way for a cleaner, greener future."[Executive Name] of Big Plastic Manufacturers echoed these sentiments, emphasizing the importance of collaboration in addressing the plastic waste crisis. "We are thrilled to partner with [Company Name] in tackling this urgent issue. Only through collaboration and innovation can we drive the necessary changes to protect our planet for future generations," [Executive Name] added.As the collaboration between [Company Name] and Big Plastic Manufacturers gains momentum, its impact is expected to be far-reaching. By leveraging their collective strengths and expertise, these industry leaders aim to lead the charge in transforming the plastic industry and concretely address the global plastic waste crisis.

Top-rated Crates Manufacturer: Quality Products for Various Needs

Title: Leading Crates Manufacturer Expands Product line to Meet Growing DemandIntroduction:In response to the rising demand for high-quality crates across various industries, a renowned crates manufacturing company is expanding its product line to cater to the evolving market needs. The company, with its extensive experience and dedication to innovation, has become a trusted name in the industry for its durable and customizable crates. This strategic move aims to meet the increasing demand while ensuring customer satisfaction through a wider range of products.Expansion of Product Line:The leading crates manufacturer recognizes the importance of adapting to changing market dynamics. By expanding its product line, the company intends to offer an even more comprehensive array of crates, accommodating diverse industry requirements. This expansion includes the introduction of several new crate designs that are developed with a focus on durability, versatility, and functionality.1. Customizable Crates:Understanding that every industry and business has unique needs, the manufacturer will now provide customized crates. These crates can be tailored to fit specific dimensions and requirements. This customization option will allow businesses to maximize their storage and transportation efficiency, promoting seamless operations.2. Heavy-Duty Crates:Recognizing the demand for sturdier crates to withstand rigorous handling, the manufacturer will be introducing heavy-duty crates. These crates will be made from high-quality materials to ensure their durability and resistance to impact. This addition will cater to industries such as construction, agriculture, and manufacturing, where the transportation of heavier goods is common.3. Stackable and Nestable Crates:Efficient space utilization is a key concern for many businesses. Therefore, the company will now offer stackable and nestable crates, providing easy storage and optimized use of available space. These crates will enable businesses to streamline their operations by reducing storage costs and enhancing logistics processes.4. Ventilated and Perforated Crates:In response to the needs of industries requiring proper airflow and ventilation for their goods, the manufacturer will introduce ventilated and perforated crates. These crates will ensure proper air circulation, preventing moisture build-up and potential damage to the stored items. This innovation will benefit industries such as agriculture, pharmaceuticals, and food processing.5. Collapsible Crates:Recognizing the need for efficient storage when crates are not in use, the manufacturer is planning to introduce collapsible crates. These crates will be foldable, allowing businesses to save valuable space when not in use. This feature will prove especially useful for industries engaging in international shipments or those requiring periodic storage.Commitment to Sustainable Practices:This expansion in the product line also aligns with the manufacturer's commitment to sustainable practices. The company recognizes the importance of minimizing the environmental impact of its operations and products. Therefore, the new range of crates will incorporate eco-friendly materials and production techniques wherever possible. By offering sustainable options, the manufacturer aims to contribute to the global sustainability goals while providing efficient solutions to businesses.Conclusion:The expansion of the leading crates manufacturer's product line signifies its dedication to meeting the evolving demands of various industries. With a focus on customization, durability, functionality, and sustainable practices, the company aims to provide an extensive range of crates suitable for diverse applications. By accommodating the needs of businesses seeking efficient storage and transportation solutions, the manufacturer solidifies its position as a reliable partner for companies across sectors. This strategic move will enhance the company's growth potential while ensuring customer satisfaction through innovative and high-quality products.