Benefits of Using a Recyclable Container for a Sustainable Lifestyle

By:Admin

Recyclable Container is pleased to announce the launch of its latest sustainable packaging solution, the Eco-FriendlyBottle. This innovative and environmentally-friendly packaging solution is designed to help businesses reduce their environmental impact and meet their sustainability goals.

Recyclable Container is a leading provider of packaging solutions for the food and beverage industry. With a strong commitment to sustainability, the company has been at the forefront of developing innovative and eco-friendly packaging solutions that help reduce waste and minimize environmental impact.

The new Eco-FriendlyBottle is a testament to Recyclable Container’s dedication to sustainability. Made from 100% recyclable materials, the Eco-FriendlyBottle is a viable alternative to traditional plastic bottles, which are a major contributor to environmental pollution. The bottle is designed to be reused, recycled, and repurposed, making it a truly sustainable packaging solution.

One of the key features of the Eco-FriendlyBottle is its durability. Despite being made from recyclable material, the bottle is designed to withstand the rigors of transportation and storage, ensuring that products are protected throughout the supply chain. This durability not only reduces the likelihood of product damage but also minimizes the need for additional packaging materials, further contributing to sustainability efforts.

In addition to its durability, the Eco-FriendlyBottle is also customizable, allowing businesses to create unique and eye-catching packaging that reflects their brand identity. This level of customization not only helps businesses stand out on the shelf but also provides an opportunity to communicate their commitment to sustainability to consumers.

Furthermore, the Eco-FriendlyBottle is fully compatible with existing recycling infrastructure, making it easy for consumers to recycle the packaging after use. This ensures that the bottle can be effectively repurposed and reduces the amount of packaging waste that ends up in landfills.

The launch of the Eco-FriendlyBottle is a significant milestone for Recyclable Container as it reinforces the company’s position as a leader in sustainable packaging solutions. By providing businesses with an alternative to traditional, non-recyclable packaging, Recyclable Container is empowering them to make a positive impact on the environment.

“We are thrilled to introduce the Eco-FriendlyBottle to the market. This packaging solution represents our commitment to sustainability and our dedication to providing businesses with eco-friendly alternatives to traditional packaging,” said [Company Spokesperson/CEO].

With the growing focus on environmental sustainability, businesses are increasingly seeking packaging solutions that not only protect their products but also minimize their impact on the environment. The Eco-FriendlyBottle is well-positioned to meet this demand by providing a sustainable packaging option that does not compromise on performance or aesthetics.

The launch of the Eco-FriendlyBottle also aligns with Recyclable Container’s broader sustainability goals. The company is dedicated to reducing its own environmental footprint and promoting sustainable practices throughout its operations. By offering the Eco-FriendlyBottle, Recyclable Container is not only empowering businesses to make more sustainable choices but also leading by example in the packaging industry.

In conclusion, the launch of the Eco-FriendlyBottle by Recyclable Container marks a significant step forward in the company’s commitment to sustainability. With its durable, customizable, and recyclable design, the Eco-FriendlyBottle offers businesses a viable alternative to traditional plastic packaging, helping them reduce their environmental impact and meet their sustainability goals. As the demand for eco-friendly packaging solutions continues to grow, the Eco-FriendlyBottle is poised to make a positive impact on the environment and lead the way towards a more sustainable future.

Company News & Blog

Leading Plastic Parts Manufacturer Reveals Innovation and Expansion Plans

Title: Leading Plastic Parts Manufacturer Sets New Industry Benchmarks for Innovation and QualityIntroduction:In today's highly competitive market, Plastic Parts Manufacturer has emerged as a renowned industry leader, consistently delivering top-notch plastic components and maintaining a strong commitment to innovation and quality. With a steadfast determination to meet evolving customer demands, the company has set new industry benchmarks through cutting-edge manufacturing processes, creative designs, and an unwavering dedication to customer satisfaction. This article delves into the phenomenal success story of Plastic Parts Manufacturer, highlighting their pioneering efforts and the impact they have made within the plastic manufacturing industry.Driving Innovation:Plastic Parts Manufacturer has always been at the forefront of innovation, consistently pushing the boundaries of what is possible within the plastic manufacturing industry. By investing heavily in research and development, the company has successfully developed innovative techniques and materials, enabling them to offer a wide range of highly functional and visually appealing plastic parts to diverse industries.Furthermore, Plastic Parts Manufacturer has fostered an environment that encourages creativity and collaboration, allowing them to work closely with clients to understand their unique needs and provide tailor-made solutions. This customer-centric approach has been instrumental in their ability to innovate and develop customized plastic parts that exceed expectations and help their clients gain a competitive edge in their respective markets.Uncompromising Quality:Plastic Parts Manufacturer firmly believes that quality is paramount in delivering exceptional products. They have implemented an extensive quality control system designed to ensure that every plastic part leaving their facilities meets the highest industry standards. By adhering to rigorous testing and inspection procedures, the company guarantees that each component is free from defects and possesses optimal durability and functionality.To achieve this level of quality, Plastic Parts Manufacturer employs a skilled workforce that undergoes regular training sessions to enhance their expertise in manufacturing techniques and quality control measures. Additionally, the company leverages advanced technology and state-of-the-art equipment, enabling them to achieve precise measurements, flawless finishes, and consistent product quality, all while adhering to environmental standards.Sustainable Manufacturing:Plastic Parts Manufacturer recognizes the importance of sustainable manufacturing practices and actively contributes to minimizing their environmental impact. They have implemented a robust environmental management system that focuses on reducing waste generation, conserving energy, and utilizing eco-friendly materials and processes wherever possible. By adopting sustainable practices, the company ensures both the longevity of their operations and the preservation of the planet.Global Reach and Clientele:The relentless pursuit of excellence has boosted Plastic Parts Manufacturer's global footprint, allowing them to serve a diverse clientele across various industries. Their reputation as a reliable and innovative plastic parts manufacturer has attracted clients ranging from the automotive, electronics, medical, and consumer products sectors, among others. Whether it be precision-molded components, custom-designed parts, or large-scale production requirements, Plastic Parts Manufacturer has the capability and expertise to cater to the specific needs of each customer.Customer Satisfaction:One of the key factors behind Plastic Parts Manufacturer's success is their unwavering commitment to customer satisfaction. The company has established long-term partnerships with their clients, garnering trust and reliance through their excellent products and exceptional customer service. By maintaining transparent communication channels, responding promptly to queries, and consistently delivering on promises, Plastic Parts Manufacturer has built a loyal customer base that spans the globe.Future Outlook:Plastic Parts Manufacturer is driven by an unyielding passion for continuous improvement and aims to further expand its global presence. By leveraging emerging technologies, staying updated on industry trends, and further enhancing their R&D capabilities, the company endeavors to pioneer even more groundbreaking innovations in plastic manufacturing. With an unwavering commitment to quality, sustainable practices, and customer satisfaction, Plastic Parts Manufacturer is poised to remain at the forefront of the industry for years to come.Conclusion:Plastic Parts Manufacturer has redefined the landscape of plastic manufacturing through their unwavering commitment to innovation, quality, and customer satisfaction. Their relentless pursuit of excellence has set new industry benchmarks and positioned them as a trusted partner for businesses across the globe. With a strong focus on sustainability and a customer-centric approach, Plastic Parts Manufacturer is advancing the industry with cutting-edge technology, customized solutions, and an unyielding dedication to quality.

Top Custom Plastic Manufacturers: Enhancing Your Product Design and Functionality

Custom Plastic Company announces new environmentally-friendly production methodsCustom Plastic Company, a leading manufacturer of plastic products, has announced the implementation of new environmentally-friendly production methods at its manufacturing plant. The company's new production methods are designed to reduce its environmental impact as well as provide its customers with sustainable, eco-friendly products.According to the company, the new production methods will include the use of recycled materials in its manufacturing processes. This means that Custom Plastic Company will be using fewer virgin materials in its production, which will significantly reduce its carbon footprint. Additionally, the company will be recycling waste materials generated during the manufacturing process, further reducing its environmental impact.The implementation of these new production methods aligns with Custom Plastic Company's commitment to sustainability. The company believes that it has a responsibility to protect the environment and reduce its impact on it. It recognizes the importance of reducing waste and conserving resources, and wants to lead by example in the industry."We understand that our operations have an impact on the environment, and we are taking steps to reduce that impact," said a spokesperson for Custom Plastic Company. "By implementing these new production methods, we can reduce our carbon footprint and provide our customers with high-quality, eco-friendly products."Custom Plastic Company's efforts to reduce its environmental impact go beyond its production methods. The company also uses biodegradable materials in its products and packaging. This means that its products will break down naturally over time, reducing the amount of waste in landfills."We are committed to making a positive impact on the environment," said the spokesperson. "Using biodegradable materials in our products and packaging is just one of the ways we are doing that. We believe that sustainability should be a priority for businesses, and we are proud to lead the way in our industry."Custom Plastic Company is confident that its new environmentally-friendly production methods will not only reduce its environmental impact but will also provide its customers with a competitive advantage. As more and more consumers become environmentally conscious, the demand for sustainable products is increasing. By producing eco-friendly products, Custom Plastic Company is meeting this demand and positioning itself as a leader in the industry."We believe that sustainability is not just good for the environment, but it's also good for business," said the spokesperson. "As more and more consumers become concerned about the environment, the demand for sustainable products is increasing. By producing eco-friendly products, we are meeting this demand and providing our customers with a competitive advantage."Custom Plastic Company's new environmentally-friendly production methods are part of its ongoing commitment to sustainability. The company believes that its efforts to reduce its environmental impact will not only benefit the planet but will also help it maintain a competitive edge in the industry."We are proud of the steps we are taking to reduce our environmental impact," said the spokesperson. "We believe that sustainability should be a priority for all businesses, and we are committed to doing our part. By using sustainable production methods and biodegradable materials, we are making a positive impact on the environment and creating value for our customers."In conclusion, Custom Plastic Company's commitment to sustainability is impressive. By implementing recyclable materials in their manufacturing plants, it reduces its carbon footprint, making it eco-friendly. Investing in biodegradable materials in their products and packaging is also another way the company is reducing its environmental impact. With this progress, customers can purchase high-quality eco-friendly products. The company's efforts to reduce its environmental impact sets an incredible example for other businesses to follow.

Manufacturing sector accounts for almost half of China's stock market value

Chinese manufacturing companies are playing a pivotal role in the country's economy, with almost half of the stock market capitalisation made up of public manufacturing firms. By the end of June 2018, publicly traded manufacturers accounted for a combined market value of ¥24.08tn ($3.47tn), representing 43.78% of the A-share market.The government’s focus on innovation-driven development has boosted the manufacturing industry, which is seen as a key pillar of the national economy. Of all 3,527 Chinese listed firms, almost two-thirds are in the manufacturing sector. The government has introduced measures from tax breaks to easier financing channels to support the real economy and bolster growth.The manufacturing sector has achieved sound growth in the first nine months of this year, buoyed by higher profits, recovering private investment, and sustained growth in high-tech and equipment manufacturing, according to official data. The Research Institute of Machinery Industry Economic & Management and the Suzhou government recently released a report outlining the importance of the manufacturing sector to China's economy. The report was presented at a forum, and Zhou Yongliang of the organisers praised the significant number of companies in smart and advanced manufacturing that went public this year. Such firms provide a positive shift in the manufacturing sector, Yongliang said.This news comes amidst the ongoing US-China trade war, with tariffs on both the Asian superpower and the US taking effect earlier this year. While their effect on the global economy remains to be seen, the tariffs had been expected to hurt companies and cost jobs in the manufacturing sector.Despite the tariffs, China remains a manufacturing hub, with factory production increasing for the 25th straight month in September. The Purchasing Managers’ Index (PMI), a key gauge of manufacturing activity, held steady at 50.8 last month, just slightly lower than August's 51.3, indicating sustained growth.However, the sector faces challenges such as rising costs, environmental regulations, and the need for technological innovation. Addressing these issues will require the Chinese government and business leaders to collaborate closely to ensure continued growth and competitiveness.While the manufacturing industry remains a stalwart of China’s economy, the country is moving towards a more service-based economy. This transition is reflected in the increasing number of companies listed in the finance, technology and healthcare sectors. Regardless of changes to the sectorial makeup of the economy, however, manufacturing is set to remain a crucial element of China's growth story for the foreseeable future.

Top Ways to Create Plastic Products for Various Industries

Pioneering Plastic Product Manufacturer Sets New Industry Standard In an age where environmental conservation and sustainability are at the forefront of public consciousness, one industry leader in plastic product manufacturing is setting a new standard for sustainability and innovation. Make Plastic Products (MPP), a leading manufacturer of plastic products, is revolutionizing the industry with their commitment to producing high-quality, eco-friendly plastic products.Founded in 2005, MPP has quickly risen to prominence as a leader in the plastic product manufacturing industry. Their state-of-the-art facilities and cutting-edge technology have positioned them at the forefront of innovation and sustainability. With a focus on producing a wide range of plastic products for various industries, MPP has made it their mission to prioritize sustainability and environmental responsibility in every aspect of their operations.One of the key factors that sets MPP apart from other plastic product manufacturers is their dedication to utilizing sustainable materials in their production processes. By incorporating recycled plastic and other eco-friendly materials into their products, MPP is reducing their environmental impact while still maintaining the high quality and durability that their products are known for. This commitment to sustainability has not only positioned MPP as an industry leader, but has also garnered them widespread acclaim from environmentally conscious consumers and businesses alike.In addition to their use of sustainable materials, MPP has also implemented innovative production methods that minimize waste and energy consumption. Their streamlined manufacturing processes and advanced technology allow them to produce plastic products with maximum efficiency and minimal environmental impact. This dedication to sustainable production has earned MPP recognition for their commitment to reducing their carbon footprint and preserving the environment for future generations.Furthermore, MPP has taken proactive steps to ensure that their products are recyclable and can be reused in a circular economy. By designing their products with recycling in mind, MPP is contributing to the creation of a more sustainable and circular approach to plastic product manufacturing. This commitment to the entire life cycle of their products showcases MPP's dedication to environmental stewardship and their understanding of the importance of responsible product design and disposal.Furthermore, MPP is continuously investing in research and development to explore new and innovative ways to further improve the sustainability of their products and operations. Their team of dedicated researchers and engineers are constantly working to develop new materials, processes, and designs that will continue to push the boundaries of eco-friendly plastic product manufacturing. This dedication to innovation and advancement has solidified MPP's reputation as a pioneer in the plastic product industry.MPP's commitment to sustainability and environmental responsibility extends beyond their manufacturing processes and products. As a socially responsible company, MPP actively participates in community service and supports various environmental initiatives. By partnering with local organizations and participating in environmental conservation projects, MPP is actively contributing to the well-being of their community and the planet.In conclusion, Make Plastic Products (MPP) has proven itself as a trailblazer in the plastic product manufacturing industry. Their unwavering commitment to sustainability, innovation, and environmental responsibility sets a new standard for the industry and paves the way for a more sustainable future. With their dedication to utilizing eco-friendly materials, reducing waste and energy consumption, and promoting recyclability, MPP exemplifies what it means to be a leader in sustainable plastic product manufacturing. As they continue to push the boundaries of innovation and sustainability, MPP is poised to shape the future of the industry and inspire positive change on a global scale.

Plastic manufacturing industry has potential to double employment and reduce import dependence: Minister Piyush Goyal

Plastic Industry Process: Understanding the Key FactorsThe plastic industry is one of the biggest contributors to the Indian economy. With an anticipated turnover of Rs 10 trillion in the next five years, the plastic manufacturing industry has huge potential for growth. In addition to generating immense employment opportunities, it can also help reduce the country’s import dependence. To achieve this goal, it is crucial to understand the plastic industry process and the critical factors that impact it.Plastic manufacturing starts with the collection of raw materials, which can be either virgin or recycled plastics. The first step in the process is polymerization, where monomers are joined together to form a polymer. This is followed by compounding, where additives such as colorants and stabilizers are added to the polymer to improve its properties. The third step is processing, including extrusion, injection molding, and blow molding, among others. Finally, the product is decorated, assembled, and packaged for shipment.The plastic industry process is influenced by many factors, including technology, raw materials, equipment, and regulations. The use of advanced technologies has revolutionized the plastic manufacturing industry, enabling it to produce high-quality and efficient products. Automation has also played a significant role in simplifying the manufacturing process, reducing costs, and improving efficiency.Another critical factor that impacts the plastic industry process is raw materials. The plastic manufacturing industry in India is dependent on imports for many of its raw materials. To reduce this dependence, the government has initiated several programs to promote the use of recycled plastics, which can significantly reduce the industry's carbon footprint.Equipment is another crucial factor in the plastic industry process. The right equipment can help optimize the manufacturing process and improve the quality of the final product. In India, the government has been providing subsidies and tax incentives to encourage the use of advanced manufacturing equipment. This has helped small and medium-scale industries improve their manufacturing processes, making them more competitive in the global market.Regulations are also a critical factor that impacts the plastic industry process. The government has implemented several regulations to mitigate the harmful effects of plastic on the environment. For instance, the government banned single-use plastic in the country, and it has been actively promoting sustainable manufacturing practices. This has encouraged the industry to adopt eco-friendly practices that align with the government's vision.In conclusion, the plastic industry process is complex and dependent on various factors. Understanding these factors is key to optimizing the process, reducing costs, and improving the quality of the final product. With the government's support, the plastic manufacturing industry has great potential to grow and contribute significantly to the Indian economy. It is critical to keep pace with global trends, technological advancements, and eco-friendly practices to remain competitive and sustainable.

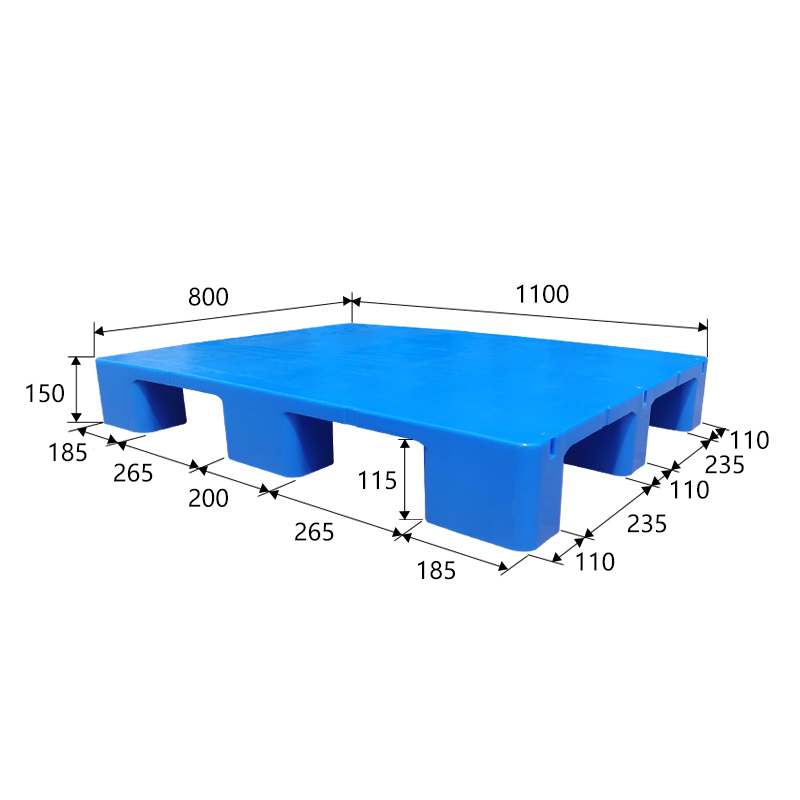

Durable and Reliable Industrial Plastic Pallets for Your Business

Industrial Plastic Pallets on the Rise: A Solution for the Modern Manufacturing IndustryIn the modern era of manufacturing, efficiency, durability, and sustainability are key factors in determining the success of a business. Companies are constantly seeking innovative solutions to streamline their operations and minimize their environmental impact. Industrial plastic pallets have emerged as a viable alternative to traditional wooden pallets, offering a range of benefits that make them an attractive option for businesses across various industries.[Company Name] has established itself as a leading provider of industrial plastic pallets, offering a diverse range of options to meet the specific needs of its customers. With a strong focus on quality, durability, and sustainability, the company has quickly become a preferred choice for businesses looking to optimize their logistics and supply chain operations.One of the key advantages of industrial plastic pallets is their durability. Unlike wooden pallets, which are susceptible to damage, warping, and decay, plastic pallets are built to withstand the rigors of modern industrial environments. This durability not only extends the lifespan of the pallets but also reduces the need for frequent replacements, resulting in cost savings for businesses in the long run.Additionally, industrial plastic pallets are inherently more hygienic than their wooden counterparts. They are resistant to moisture, mold, and pests, making them particularly well-suited for industries that require strict adherence to cleanliness and sanitation standards, such as food and pharmaceutical manufacturing.Furthermore, plastic pallets are lightweight yet strong, allowing for easier handling and transportation. This can lead to improved efficiency in loading and unloading processes, as well as reduced fuel consumption and emissions from transportation vehicles. The environmental impact of plastic pallets is further reduced by their recyclability, with many companies opting to use recycled plastic in the manufacturing of their pallets.With their consistent size and shape, industrial plastic pallets also contribute to the standardization of logistics processes, facilitating seamless integration into automated warehouse systems and reducing the risk of product damage during handling and storage.[Company Name] is committed to providing sustainable solutions to its customers, and its industrial plastic pallets are a testament to this dedication. By offering a product that is not only durable and efficient but also environmentally friendly, the company is helping businesses align with their corporate social responsibility goals and reduce their carbon footprint.Furthermore, [Company Name] places a strong emphasis on customer satisfaction, working closely with businesses to understand their specific needs and offer customized solutions that optimize their logistics and supply chain operations. Through ongoing research and development, the company continually strives to innovate and improve its product offerings, ensuring that its customers have access to the latest advancements in industrial plastic pallet technology.As the demand for sustainable and efficient logistics solutions continues to grow, industrial plastic pallets are poised to play an increasingly important role in the modern manufacturing industry. With their numerous benefits and cost-saving potential, businesses are recognizing the value of investing in high-quality plastic pallets to improve their operations and remain competitive in the market.In conclusion, [Company Name] has established itself as a trusted provider of industrial plastic pallets, offering a range of durable, efficient, and sustainable solutions to businesses across various industries. With a strong focus on quality, innovation, and customer satisfaction, the company is well-positioned to meet the evolving needs of the modern manufacturing industry, and its industrial plastic pallets are sure to play a crucial role in the ongoing quest for efficiency and sustainability.As businesses continue to prioritize sustainability and efficiency in their operations, the demand for industrial plastic pallets is expected to rise, and [Company Name] is ready to meet this demand with its high-quality, environmentally friendly product offerings.

The Ultimate Guide to Plastic Pallets: Experts Share Tips and Advice

Plastic Pallet Experts (PPE), a leading provider of plastic pallet solutions, has been making waves in the industrial packaging industry with its innovative products and commitment to sustainability. With a wide range of plastic pallets designed for various applications, PPE has become a go-to choice for companies looking for durable and eco-friendly pallet solutions.Founded in [year], PPE has established itself as a reliable and customer-focused company that prioritizes quality, innovation, and environmental responsibility. The company's strong commitment to sustainability is evident in its use of recycled materials and its efforts to reduce the environmental impact of its products.One of the key strengths of PPE is its diverse range of plastic pallets, catering to the needs of various industries such as food and beverage, pharmaceuticals, automotive, and more. Whether it's rackable pallets for warehouse storage, nestable pallets for efficient shipping, or high-capacity pallets for heavy-duty applications, PPE has a solution for every requirement.The company's plastic pallets are known for their durability, hygienic properties, and compatibility with automated systems. This makes them an ideal choice for companies looking to optimize their supply chain operations and reduce the risk of product damage during handling and transportation.In addition to offering a wide range of standard pallets, PPE also provides custom pallet solutions tailored to specific customer requirements. This includes custom sizes, colors, and load capacities, ensuring that each pallet is optimized for its intended use.Furthermore, PPE's commitment to sustainability is reflected in its closed-loop recycling program, which allows customers to return used pallets for recycling and reprocessing. This not only reduces waste but also promotes the circular economy by giving new life to old pallets.With a strong focus on customer satisfaction, PPE offers excellent customer service and technical support, ensuring that customers receive the right pallet solution for their needs. This includes expert advice on pallet selection, as well as assistance with pallet design and customization.As the demand for sustainable and durable pallet solutions continues to grow, PPE remains at the forefront of the industry with its innovative products and customer-centric approach. The company's dedication to quality, environmental responsibility, and customer satisfaction sets it apart as a leader in the plastic pallet market.Moving forward, PPE is poised to expand its product range and reach new markets, solidifying its position as a trusted provider of plastic pallet solutions. With a focus on continuous improvement and a commitment to meeting the evolving needs of its customers, PPE is set to remain a driving force in the industry for years to come.

Efficient Fabrication and Sub-Assembly Operations for Meeting Production Needs

In today's fast-paced and ever-evolving industrial landscape, the need for plastic fabrication companies has become more significant than ever before. From automotive to aerospace, from pharmaceuticals to electronics, plastic fabrication plays a crucial role in almost every industry. It is the process of designing, prototyping, manufacturing, and assembling plastic parts for the production of different products.Basic Rubber & Plastics Co. is a renowned name in the field of plastic fabrication companies. With an experience of over 70 years, the company has emerged as a leader in plastic fabrication and sub-assembly. With a state-of-the-art facility and a team of highly-skilled engineers and technicians, Basic Rubber & Plastics Co. offers a wide range of fabrication and sub-assembly services to its clients.Fabrication is a vital process in the production of plastic parts. At Basic Rubber & Plastics Co., the company has the capability to efficiently set up and tear down the fabrication and sub-assembly operations needed to meet the customer's needs. The company uses the latest manufacturing techniques and equipment to ensure the highest quality of plastic parts, meeting the exact specifications of the customers.Basic Rubber & Plastics Co. has the expertise to provide a wide range of plastic fabrication services, including injection molding, vacuum forming, thermoforming, rotational molding, and blow molding. Whether you need complex shapes or intricate designs, Basic Rubber & Plastics Co. has the skills and expertise to fabricate plastic parts of any size and complexity.The company offers sub-assembly services, wherein they combine various fabricated parts to create a finished product. This sub-assembly often involves intricate and delicate assembly work, such as bonding, welding, and riveting plastic parts. Basic Rubber & Plastics Co. ensures that such sub-assemblies are carried out with the utmost precision and care, adhering to the highest quality standards.Basic Rubber & Plastics Co. has built a reputation for offering unmatched quality and customer service to its clients. The company strives to achieve customer satisfaction by providing innovative solutions, competitive pricing, and timely delivery of the products. The company has a proven track record of delivering exceptional fabrication and sub-assembly services to a diverse range of industries, including automotive, aerospace, medical, consumer goods, and more.In conclusion, in today's highly competitive market, plastic fabrication companies have become an integral part of the manufacturing industry. Basic Rubber & Plastics Co. is a leading plastic fabrication company that offers a wide range of services, including fabrication and sub-assembly. The company's state-of-the-art facilities and highly-skilled engineers and technicians ensure the highest quality of plastic parts, meeting the exact specifications of the customers. If you are looking for a reliable and trustworthy plastic fabrication company, Basic Rubber & Plastics Co. is the ideal partner for your manufacturing needs.

Top Plastic Mould Manufacturer Offers Modern Chair Moulding Solutions

Plastic White Modern Table and Chair Mould Manufacturer Makes Chair –Uniquetech Mould and PlasticPlastic furniture has become the popular choice in modern homes because of the benefits they offer. Not only are they lightweight, but they are also available in various sizes, shapes, and colors to match your home decor. This has increased the demand for plastic furniture, and manufacturers have been striving to meet the customer's needs. One of the leading plastic commodity mould manufacturers is Uniquetech Mould and Plastic.Uniquetech Mould and Plastic has been in the industry for over a decade. They specialize in making plastic molds for household items, toys, electronic gadgets, and automobile parts, among others. The company has successfully completed countless projects and has earned a reputation for delivering high-quality products.Their success can be attributed to their expertise and equipment. The company has a team of skilled professionals who are conversant with 3D technologies and use them to design the molds. They also use advanced machinery that operates at high speeds to produce the molds, reducing the turnaround time.Their latest project, a plastic white modern table and chair, has caught the attention of many. The chair is designed for comfort, and its streamlined features make it easy to move around the house. The chair's legs are made of sturdy plastic that can withstand heavy loads, ensuring its durability. The chair's base is wide and stable, making it the perfect addition to your home.The company uses high-quality materials to make the molds, ensuring their durability. They use 45#, P20, 2738, 2344, 2316, 718, S136, H13 steel to make the molds. The mold base is made of LKM, HASCO, DME, or according to the customer's request. Uniquetech Mould and Plastic ensure that the mold cavity is designed to meet the customer's requirements. They can make a single mold or multiple molds, depending on the customer's needs.The runner system is another crucial aspect of the mold that Uniquetech Mould and Plastic take seriously. They use either a cold or hot runner system, depending on the product's requirements. The surface treatment is also critical in the mold-making process. The company ensures that the surface is polished and smooth to give the final product a perfect finish.Uniquetech Mould and Plastic also take environmental protection seriously. They have put in place measures to ensure that the mold-making process is eco-friendly. They use materials that are recyclable, which reduces their carbon footprint. The company also encourages their customers to recycle the plastic products they purchase, reducing plastic waste in the environment.In conclusion, Uniquetech Mould and Plastic is a leading plastic commodity mould manufacturer, and their latest project, a plastic white modern table and chair, is a testament to their expertise. They use high-quality materials, advanced machinery, and skilled professionals to design the molds. They also take environmental protection seriously, making them an excellent choice for customers who wish to reduce their carbon footprint. The plastic white modern table and chair are perfect for modern homes, offering comfort, style, and durability. Uniquetech Mould and Plastic are a company that you can trust to deliver high-quality products.

Seamless and Gap-Free Hygienic Plastic Pallet for Food Industry

When it comes to food safety, every little detail counts. From the harvesting of ingredients to the packaging and transportation of the final product, everything must be handled with the utmost care and attention. One aspect of food transportation that is often overlooked is the pallet on which the product is stored and transported. This is where the hygienic plastic pallet comes in.Hygienic plastic pallets are specially designed to eliminate the risk of contamination from bacteria and other harmful microorganisms. They are made from high-density polyethylene (HDPE) or other food-grade plastics, which are non-porous and resistant to moisture, chemicals, and temperature changes. Unlike wooden pallets, which can harbor bacteria in their pores and cracks, hygienic plastic pallets have a smooth surface that can be easily sanitized and disinfected.One of the key features of hygienic plastic pallets is their seamless design. Traditional pallets have sidewall seams, gaps, and holes that can trap moisture, dirt, and bacteria. These hard-to-reach areas can be difficult to clean and sanitize, creating a breeding ground for pathogens. Hygienic plastic pallets, on the other hand, have no sidewall seams or other bacteria traps, which makes them much easier to maintain and keep clean.Another benefit of hygienic plastic pallets is their durability and longevity. Unlike wooden pallets, which can splinter, crack, and break over time, plastic pallets are designed to withstand heavy loads and rough handling. They can also be reused multiple times, reducing the need for frequent replacements and minimizing waste.Hygienic plastic pallets are also more sustainable than traditional pallets. They can be recycled at the end of their lifespan, which reduces their environmental impact and conserves resources. Additionally, plastic pallets are lightweight, which reduces fuel consumption and transportation costs.In conclusion, hygienic plastic pallets are an essential component of food safety and quality assurance. They provide a seamless, easy-to-clean surface that eliminates the risk of contamination from bacteria and other harmful microorganisms. Their durability, longevity, and sustainability make them a cost-effective and eco-friendly alternative to traditional wooden pallets. If you're in the food industry, consider making the switch to hygienic plastic pallets to ensure the safe and efficient transportation of your products.