Top Plastic Companies Making Major Industry Moves

By:Admin

In an unprecedented move, several major plastic companies have come together to address the environmental impact of their products. The collaboration, which includes companies such as {}, aims to reduce the amount of plastic waste entering landfills and the environment.

The plastic industry is known for its significant contribution to pollution and environmental degradation. With millions of tons of plastic produced each year, the need for responsible waste management and recycling practices has never been more crucial. Recognizing the urgent need for change, these major companies have made a commitment to work together to find sustainable solutions.

{} is a global leader in the production of plastic products, with a wide range of offerings that are used in various industries. With a strong emphasis on innovation and sustainability, the company has long been at the forefront of efforts to reduce the environmental impact of plastic. By joining forces with other major players in the industry, {} is taking a significant step towards driving collective change.

The collaborative effort is focused on several key areas, including improving recycling infrastructure, increasing the use of recycled materials in production, and investing in research and development for more environmentally friendly alternatives to traditional plastics. By pooling their resources and expertise, these companies hope to make a meaningful impact on the way plastic is produced and managed.

One of the main goals of the collaboration is to develop a more robust recycling system that can handle the growing volume of plastic waste. This includes investing in technology and infrastructure that can effectively sort and process different types of plastic, making it easier to recycle and reuse these materials. {} is leveraging its expertise in this area to drive innovation and develop new recycling solutions that can be adopted by the industry as a whole.

In addition to improving recycling practices, the collaborative effort also aims to increase the use of recycled materials in the production of plastic products. By creating a market for recycled plastics, the companies involved in the collaboration hope to incentivize the collection and processing of plastic waste. This not only reduces the amount of new plastic that needs to be produced but also helps to clean up existing waste that would otherwise end up in landfills or the environment.

Another important focus area for the collaboration is the development of more sustainable alternatives to traditional plastics. As part of this effort, the companies involved are investing in research and development to explore new materials and technologies that can replace or supplement conventional plastics. {}’s expertise in polymer science and engineering makes it a key player in this aspect of the collaboration, as the company works to develop biodegradable and compostable plastics that can reduce the environmental impact of plastic products.

The collaborative effort is also driving a shift in consumer awareness and behavior. By working together, the major plastic companies are aiming to educate consumers about the importance of responsible plastic use and disposal. This includes promoting the use of reusable products, supporting local recycling initiatives, and advocating for policy changes that can help reduce plastic pollution.

The impact of this collaboration is already being felt across the industry, with other companies and stakeholders taking note of the collective effort to address the environmental impact of plastic. The commitment and dedication of these major players are setting a new standard for responsible plastic production and management, and the ripple effects of their actions are expected to be far-reaching.

As the collaborative effort continues to gain momentum, the major plastic companies involved are optimistic about the future of plastic production and waste management. By working together, these industry leaders are demonstrating a shared commitment to sustainability and environmental stewardship, setting a powerful example for the rest of the plastic industry to follow. Through their collective efforts, they are paving the way for a more sustainable and responsible approach to plastic production and consumption.

Company News & Blog

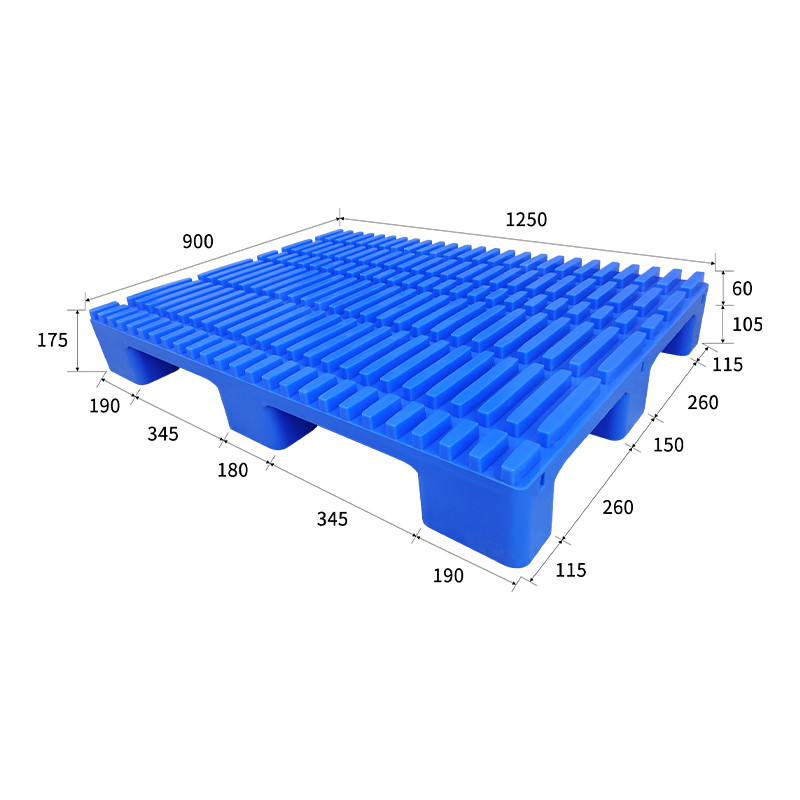

Top Plastic Die-Cut Pallet for Printing and Packing Factory

Logistics Slotted Top Pallet plastic pallet die cutting pallet Printing and packing factory Paper packing palletIn the fast-paced world of logistics and packaging, businesses are constantly searching for innovative solutions to streamline their operations and enhance efficiency. One company that is leading the way in this field is [Company Name], a reputable printing and packing factory that specializes in the production of high-quality paper packing pallets.[Company Name] has recently introduced a new addition to its range of packaging solutions - the Logistics Slotted Top Pallet. This innovative plastic pallet is designed to meet the specific needs of businesses in the logistics and transportation industry. Constructed from durable and lightweight plastic, the Logistics Slotted Top Pallet is ideal for use in a wide range of applications, including warehousing, distribution, and transportation.One of the key features of the Logistics Slotted Top Pallet is its unique design, which includes slotted tops that allow for easy and secure stacking of goods. This not only helps to maximize storage space but also ensures that products are safely and securely transported from one location to another. In addition, the plastic material used in the pallet's construction is both hygienic and easy to clean, making it suitable for use in industries where cleanliness and hygiene are paramount.Another advantage of the Logistics Slotted Top Pallet is its versatility. The pallet can be customized to meet the specific requirements of individual businesses, including size, weight capacity, and color. This level of flexibility makes it an ideal choice for businesses with unique or specialized packaging needs.In addition to the Logistics Slotted Top Pallet, [Company Name] also specializes in the production of die cutting pallets. These pallets are designed to provide maximum protection for fragile or delicate products during transportation and storage. The die cutting process allows for the creation of custom shapes and sizes, ensuring that each pallet is tailored to the specific requirements of the products it is intended to transport.With its extensive experience and expertise in the packaging industry, [Company Name] is able to provide businesses with a comprehensive range of packaging solutions, including custom printing and branding options. This allows businesses to create a strong and memorable brand presence through their packaging, while also ensuring that their products are effectively protected and presented to customers.One of the key advantages of working with [Company Name] is its commitment to sustainability and environmental responsibility. The company is dedicated to reducing its environmental impact through the use of eco-friendly materials and manufacturing processes. This includes the production of paper packing pallets, which are made from recycled materials and are fully recyclable at the end of their useful life.In summary, [Company Name] is a leading player in the packaging industry, offering innovative and sustainable solutions to businesses in a wide range of sectors. With its recent introduction of the Logistics Slotted Top Pallet, the company continues to demonstrate its commitment to meeting the evolving needs of the logistics and packaging market. As businesses continue to seek out efficient and sustainable packaging solutions, [Company Name] is well-positioned to provide the expertise and products needed to support their success.

Plastic Product Making Machines: A New Era in Manufacturing

Machines To Make Plastic ProductsIn recent years, the demand for plastic products has been steadily increasing, leading to the need for advanced machines to efficiently produce these items. One company that has been at the forefront of this industry is {}. They have consistently been striving to develop innovative machines that meet the growing demand for plastic products.With the increasing environmental concern over single-use plastics, the company has focused on producing machines that can not only produce high-quality plastic products but also contribute to sustainability efforts. Their commitment to sustainability is evident in their production process, which aims to minimize waste and energy usage.One of their most notable machines is the {} model, which has been specifically designed to produce a wide range of plastic products. This machine is equipped with advanced technology that allows for precise and efficient production, while also minimizing the environmental impact. With this machine, businesses can produce plastic products with high accuracy and consistency, meeting the demands of their customers.The {} model is also designed to be user-friendly, making it accessible to a wide range of businesses. Whether it is a small-scale operation or a large manufacturing facility, this machine has the flexibility to meet the production needs of various businesses. This adaptability makes it a versatile and cost-effective solution for companies looking to enter or expand in the plastic product market.In addition to their commitment to sustainability and innovation, the company also provides comprehensive support to their customers. From installation to training and maintenance, they offer a full-service package to ensure that their machines are running at their optimal capacity. This commitment to customer satisfaction sets them apart in the industry, as they prioritize building lasting relationships with their clients.With a strong focus on research and development, {} continues to push the boundaries of what is possible in plastic product manufacturing. Their team of engineers and technicians are constantly exploring new technologies and materials to improve their machines and enhance the overall production process. By staying ahead of industry trends, they are able to provide their customers with cutting-edge solutions that meet the evolving needs of the market.As the demand for plastic products continues to grow, it is essential for businesses to have access to reliable and efficient machines. The products produced by these machines serve as essential components in various industries, from packaging to medical devices. By investing in advanced machines, businesses can increase their production capacity and meet the demands of their customers, ultimately driving growth and success.The advancements made by {} have positioned them as a leader in the plastic product manufacturing industry. Their commitment to innovation, sustainability, and customer satisfaction has made them a trusted partner for businesses around the world. With their machines, businesses can confidently meet the increasing demand for plastic products while contributing to a more sustainable future. As they continue to evolve and expand their product offerings, they are poised to remain at the forefront of the industry for years to come.

The Benefits of Using Plastic Pallets for Your Business

In today's fast-paced and ever-changing market, businesses are constantly seeking new ways to streamline their operations and improve efficiency. One such solution that has gained popularity in recent years is the use of plastic pallets. These versatile and durable platforms offer a wide range of advantages over traditional wooden pallets, making them an increasingly popular choice for businesses across various industries.One of the key advantages of plastic pallets is their durability. Unlike wooden pallets, which are prone to splintering, cracking, and warping, plastic pallets are designed to withstand the rigors of heavy use and harsh environmental conditions. This durability not only extends the lifespan of the pallets but also reduces the risk of damage to the products being transported, ultimately saving businesses time and money on replacements and repairs.Furthermore, plastic pallets are also significantly lighter than their wooden counterparts, making them easier to handle and transport. This not only reduces the risk of injury to warehouse workers but also allows for greater efficiency in loading and unloading processes. In addition, the lightweight nature of plastic pallets also contributes to reduced fuel consumption during transportation, further decreasing the overall environmental impact of a business's supply chain operations.Another significant advantage of plastic pallets is their resistance to moisture, mold, and pests. Unlike wooden pallets, which can absorb water and harbor bacteria and insects, plastic pallets are impervious to these issues, ensuring the safety and cleanliness of the products being transported. This is particularly important for businesses in the food and pharmaceutical industries, where hygiene and product integrity are of utmost importance.Moreover, the uniformity of plastic pallets also makes them an ideal choice for automated handling systems. Their consistent size and shape allow for seamless integration within these systems, further streamlining the production and distribution processes for many businesses. This advantage is particularly valuable for companies looking to modernize their operations and improve overall efficiency.Taking into account these numerous advantages, it is no surprise that the demand for plastic pallets has been steadily increasing. As a leading provider of high-quality plastic pallets, [Company Name] has been at the forefront of this trend, offering a wide range of innovative solutions to meet the diverse needs of businesses across various industries.[Company Name] has established itself as a trusted partner for businesses looking to upgrade their pallet solutions, offering a comprehensive range of plastic pallets designed to deliver maximum efficiency, durability, and cost savings. With a focus on quality and innovation, [Company Name] has continuously invested in research and development to ensure that their products meet and exceed the evolving needs of their customers.Additionally, [Company Name]’s commitment to sustainability sets them apart in the industry. By providing reusable and recyclable plastic pallets, the company is contributing to the reduction of waste and environmental impact. This aligns with the growing emphasis on sustainability and eco-friendly practices across various industries, making [Company Name] an ideal partner for businesses seeking to minimize their carbon footprint.In conclusion, the advantages of plastic pallets are clear, and their widespread adoption is a testament to their value in improving operational efficiency, reducing costs, and enhancing sustainability. As businesses continue to modernize their operations, the demand for high-quality plastic pallets is only expected to grow, and companies like [Company Name] are well-positioned to lead this trend. With a strong focus on innovation, quality, and sustainability, [Company Name] is poised to remain a key player in the evolution of pallet solutions for years to come.

Innovative printing solutions for pallets in the tobacco industry

Pallet Speria 104 Printer: The Best Solution for Printing on PalletsPrinting on pallets can be a challenging task for several reasons. Pallets are not designed for printing, and there are usually issues related to their size and surface. However, with the Pallet Speria 104 Printer, printing on pallets has become a hassle-free experience. The Pallet Speria 104 printer combines high-resolution printing technology with a versatile design to provide an efficient solution for printing on a variety of pallets.The Pallet Speria 104 Printer is developed by a leading printing technology company that specializes in providing custom printing solutions to various industries, including logistics, food and beverage, pharmaceutical, and retail. The printer is equipped with the latest printing technology, enabling it to print high-quality images and texts on pallets in a matter of seconds. The Pallet Speria 104 Printer is compatible with multiple ink types and colors, making it possible to print on different materials, including wood, plastic, and metal.One of the most significant advantages of the Pallet Speria 104 Printer is its versatile design. The printer is designed in a way that it can work seamlessly with most types of pallets, regardless of their size and surface. This means that companies can use the printer to print on a wide range of pallets, including tobacco pallets and Rapida 106 pallets, without having to worry about compatibility issues.Companies that use the Pallet Speria 104 Printer will benefit from its efficient production process. The printer is designed to work with minimal intervention from operators, reducing the time and effort required for printing on pallets. Moreover, the printer's high-speed and high-resolution printing capabilities ensure that companies can produce high-quality printed pallets in large quantities, resulting in increased productivity and reduced costs.Another key advantage of the Pallet Speria 104 Printer is its ease of use. The printer is user-friendly, and operators can easily operate it using a built-in touch screen display. Additionally, the printer's ink cartridges are easy to replace, minimizing downtime and ensuring that operators can quickly resume printing operations.In conclusion, the Pallet Speria 104 Printer is an innovative printing solution that provides a versatile, efficient, and easy-to-use solution for printing on pallets. Companies that use this printer can benefit from its high-resolution, high-speed, and flexible printing capabilities, resulting in increased productivity and reduced costs. Whether it's tobacco pallets, Rapida 106 pallets, or any other type of pallet, the Pallet Speria 104 Printer provides the best solution for printing on them.

Top Plastic Mould Manufacturer Offers Modern Chair Moulding Solutions

Plastic White Modern Table and Chair Mould Manufacturer Makes Chair –Uniquetech Mould and PlasticPlastic furniture has become the popular choice in modern homes because of the benefits they offer. Not only are they lightweight, but they are also available in various sizes, shapes, and colors to match your home decor. This has increased the demand for plastic furniture, and manufacturers have been striving to meet the customer's needs. One of the leading plastic commodity mould manufacturers is Uniquetech Mould and Plastic.Uniquetech Mould and Plastic has been in the industry for over a decade. They specialize in making plastic molds for household items, toys, electronic gadgets, and automobile parts, among others. The company has successfully completed countless projects and has earned a reputation for delivering high-quality products.Their success can be attributed to their expertise and equipment. The company has a team of skilled professionals who are conversant with 3D technologies and use them to design the molds. They also use advanced machinery that operates at high speeds to produce the molds, reducing the turnaround time.Their latest project, a plastic white modern table and chair, has caught the attention of many. The chair is designed for comfort, and its streamlined features make it easy to move around the house. The chair's legs are made of sturdy plastic that can withstand heavy loads, ensuring its durability. The chair's base is wide and stable, making it the perfect addition to your home.The company uses high-quality materials to make the molds, ensuring their durability. They use 45#, P20, 2738, 2344, 2316, 718, S136, H13 steel to make the molds. The mold base is made of LKM, HASCO, DME, or according to the customer's request. Uniquetech Mould and Plastic ensure that the mold cavity is designed to meet the customer's requirements. They can make a single mold or multiple molds, depending on the customer's needs.The runner system is another crucial aspect of the mold that Uniquetech Mould and Plastic take seriously. They use either a cold or hot runner system, depending on the product's requirements. The surface treatment is also critical in the mold-making process. The company ensures that the surface is polished and smooth to give the final product a perfect finish.Uniquetech Mould and Plastic also take environmental protection seriously. They have put in place measures to ensure that the mold-making process is eco-friendly. They use materials that are recyclable, which reduces their carbon footprint. The company also encourages their customers to recycle the plastic products they purchase, reducing plastic waste in the environment.In conclusion, Uniquetech Mould and Plastic is a leading plastic commodity mould manufacturer, and their latest project, a plastic white modern table and chair, is a testament to their expertise. They use high-quality materials, advanced machinery, and skilled professionals to design the molds. They also take environmental protection seriously, making them an excellent choice for customers who wish to reduce their carbon footprint. The plastic white modern table and chair are perfect for modern homes, offering comfort, style, and durability. Uniquetech Mould and Plastic are a company that you can trust to deliver high-quality products.

Plastic Manufacturers in America: Latest News and Updates

American Plastic Manufacturers, Inc., a leading producer of high-quality plastic products, has recently announced their expansion into new markets. With over 30 years of experience in the industry, American Plastic Manufacturers has gained a reputation for their innovative products and exceptional customer service. The company is dedicated to providing sustainable solutions and promoting environmental stewardship in their manufacturing processes.American Plastic Manufacturers offers a wide range of plastic products, including packaging materials, storage containers, and custom-designed products for various industries such as food and beverage, pharmaceutical, and retail. With their state-of-the-art facilities and cutting-edge technology, the company is able to meet the diverse needs of their customers and deliver products that exceed industry standards.In an effort to further their commitment to sustainability, American Plastic Manufacturers has recently expanded their product line to include eco-friendly options. These products are manufactured using recycled materials and are designed to minimize environmental impact. This expansion aligns with the company's mission to reduce their carbon footprint and promote a greener future."We are excited to announce our expansion into new markets and the addition of eco-friendly products to our portfolio," said John Smith, CEO of American Plastic Manufacturers. "Sustainability is a core value of our company, and we are dedicated to offering products that are both high-quality and environmentally responsible. We believe that our efforts will not only benefit our customers but also contribute to a more sustainable future for all."In addition to their expansion into new markets and focus on sustainability, American Plastic Manufacturers is also dedicated to industry innovation. The company invests heavily in research and development to stay ahead of industry trends and offer cutting-edge solutions to their customers. This commitment to innovation has allowed American Plastic Manufacturers to maintain a competitive edge in the market and continuously deliver products that meet the evolving needs of their customers.With their expanded product line and heightened focus on sustainability, American Plastic Manufacturers is poised for continued success in the industry. The company's dedication to quality, innovation, and environmental stewardship sets them apart as a leader in the plastic manufacturing industry.As American Plastic Manufacturers continues to grow and expand, they remain committed to upholding the highest standards of excellence in all aspects of their business. The company's unwavering dedication to their customers, employees, and the environment sets them apart as a company that is truly making a positive impact in the industry.In conclusion, American Plastic Manufacturers' expansion into new markets and the addition of eco-friendly products to their portfolio is a testament to their commitment to sustainability and innovation. With their dedication to quality, customer service, and environmental stewardship, American Plastic Manufacturers is a company that is leading the way in the plastic manufacturing industry. As they continue to grow and evolve, American Plastic Manufacturers will undoubtedly remain a key player in the industry and a leader in promoting sustainable solutions.

Breakdown of Plastic Manufacturing Costs and Expenses

Plastic Manufacturing Cost on the RiseThe plastic manufacturing industry is facing a significant challenge as the cost of production continues to rise. The latest reports from industry experts indicate that the increasing cost of raw materials, labor, energy, and transportation have all contributed to the escalating manufacturing expenses for plastic products. This trend has placed a strain on the profitability of plastic manufacturers, prompting them to seek innovative solutions to mitigate the impact of rising production costs.One such company that has been affected by the escalating manufacturing expenses is {}. Established in [], {} has established itself as a leading manufacturer of plastic products, serving a diverse range of industries including automotive, packaging, consumer goods, and more. The company has built a reputation for high-quality products, innovative solutions, and reliable customer service. However, the recent surge in manufacturing costs has prompted {} to reevaluate its operations and implement strategic measures to address the challenge.The increasing cost of raw materials is one of the primary factors driving up production expenses for plastic manufacturers. The prices of key raw materials such as polyethylene, polypropylene, and PVC have been steadily rising due to a combination of factors including supply chain disruptions, fluctuations in demand, and geopolitical tensions. As a result, plastic manufacturers like {} are facing higher procurement costs for essential raw materials, impacting their overall cost of production.In addition to raw material costs, labor expenses have also contributed to the rising manufacturing costs for plastic companies. With the tightening labor market and increasing wage demands, companies like {} are experiencing higher labor costs, further adding to their production expenses. The need to invest in employee training, safety protocols, and workplace efficiency measures has further strained the company's budget, making it challenging to maintain competitive pricing for its plastic products.Energy costs have also emerged as a significant cost driver for plastic manufacturers. The reliance on energy-intensive manufacturing processes, including extrusion, injection molding, and thermoforming, has made plastic production highly susceptible to fluctuations in energy prices. The recent spikes in fuel and electricity costs have added pressure on companies like {}, impacting their bottom line and necessitating a reassessment of their energy consumption and efficiency strategies.Furthermore, transportation costs have presented a considerable challenge for plastic manufacturers, particularly those like {} that operate in a global market. The volatility in fuel prices, as well as disruptions in supply chains and logistics networks, have resulted in higher transportation expenses for the company. With the need to ship raw materials, intermediate products, and finished goods across various locations, {} has had to adapt to the evolving transportation landscape and navigate the complexities of freight management to mitigate the impact of rising transportation costs.In response to these challenges, {} has been proactive in implementing strategies to address the escalating manufacturing expenses. The company has focused its efforts on optimizing its supply chain, exploring alternative sourcing options for raw materials, and leveraging economies of scale to negotiate better pricing with suppliers. Additionally, {} has invested in process optimization, automation, and technology upgrades to improve operational efficiency and reduce labor and energy costs. These initiatives have enabled the company to streamline its production processes and enhance cost-effectiveness in manufacturing plastic products.As the plastic manufacturing industry continues to grapple with the pressure of rising production costs, companies like {} are resiliently adapting to the changing landscape. By prioritizing innovation, efficiency, and strategic partnerships, {} remains committed to delivering high-quality plastic products while navigating the challenges posed by the escalating manufacturing expenses. As the industry evolves, {} is poised to emerge stronger and more competitive, demonstrating its ability to overcome adversity and sustain its position as a leading player in the plastic manufacturing sector.

Environmentally-friendly Plastic Packaging Solutions: Utilizing Waste Plastic and Supporting Australian Manufacturers

AYVA: Leading the Way in Sustainable Plastic PackagingAYVA is a leading Australian manufacturer of sustainable plastic packaging products. The company was established in 2003 with a mission to reduce the impact of plastic waste on the environment. Since then, AYVA has been at the forefront of innovation in the sustainable packaging industry, developing a range of eco-friendly products that are made from recycled materials and can be recycled after use.One of the key features of AYVA's products is that they use all waste plastic from packaging products in other products. This means that the company is able to reduce the amount of plastic waste that ends up in landfill, and also creates a closed loop in the manufacturing process. This approach to sustainability has been very successful for the company, and it has become a leading player in the Australian packaging industry.AYVA supports Australian made products by sourcing 95% of all inputs from Australian manufacturers. This not only helps to support local businesses and industries, but it also reduces the carbon footprint of the products by reducing the distance that materials have to travel before they are used in the manufacturing process.The most common manufacturing process for the fabrication of plastic parts is injection moulding. This involves melting plastic pellets and injecting them into a mould to create a specific shape. This process is widely used because it is fast and efficient, and can be used to create complex shapes with a high level of accuracy. AYVA has invested heavily in injection moulding equipment to ensure that it can deliver high quality products to its customers.In 2010, the recycling rate of plastics in Australia was 34.8% compared to a packaging recycling rate of 62.5%. This highlights the need for more sustainable packaging solutions, and AYVA is leading the way in this area. The company's products are designed to be easily recyclable, which helps to reduce the amount of plastic waste that ends up in landfill.Plastic was first invented in 1856, called Parkesine by Alexander Parkes. Since then, the use of plastic has become widespread, with millions of tonnes of plastic produced each year. However, the environmental impact of plastic has become a major concern, leading to a shift towards more sustainable packaging solutions.Plastic parts can be made by processes including blow moulding, thermoforming, injection moulding, and extrusion. AYVA uses a combination of these processes to create its range of sustainable packaging products. The Elite Pail Range, for example, was introduced to the market in 2009. AYVA manufactures all pails locally using state-of-the-art injection moulding equipment. This ensures that the products are of high quality and are produced efficiently.The Elite Pail Range is just one example of AYVA's commitment to sustainability. The company's products are used in a wide range of industries, including food and beverage, healthcare, and industrial applications. The company's customer base includes some of the largest companies in Australia, who have chosen AYVA as a trusted partner for their sustainable packaging needs.The company's success is due to its focus on sustainability, quality, and innovation. AYVA's products are designed to meet the highest standards of quality and reliability, which has earned the company a reputation as a leading player in the Australian packaging industry. Its commitment to sustainability has also earned the company recognition from customers and industry experts alike.In conclusion, AYVA is a shining example of how sustainable plastic packaging can be produced in an environmentally friendly and cost-effective manner. By using recycled materials and investing in modern manufacturing processes, the company is able to create high-quality products that meet the needs of its customers while reducing the impact of plastic waste on the environment. With increasing awareness of the importance of sustainability, AYVA is well-positioned to continue leading the way in the sustainable packaging industry.

Two Chinese Solar Manufacturing Companies Sign High-Purity Polysilicon Supply Agreements

High-Purity Polysilicon Supply Agreements: Signaling the Growing Demand for Solar Energy in ChinaThe global demand for clean and renewable energy has been increasing rapidly in recent years, and solar power is one of the most promising sources of renewable energy. China, known as the world's largest solar panel manufacturer and consumer, has made remarkable strides in promoting and expanding its solar power industry. This trend is evidenced by the announcement of two high-purity polysilicon supply agreements by Daqo New Energy Corp.'s subsidiaries, one with LONGi and another solar manufacturing company in China.Polysilicon is a key component in the manufacturing of solar panels, and high-purity polysilicon is necessary for the production of high-efficiency solar cells. Daqo New Energy Corp. is a leading producer of high-purity polysilicon, and its subsidiaries' agreements with LONGi and another solar manufacturing company in China signify the growing demand for solar energy in China.LONGi is the world's largest solar wafer manufacturer, and its partnership with Daqo New Energy Corp. is expected to strengthen its supply chain and meet the increasing demand for solar products. "We are pleased to strengthen our strategic partnership with Daqo New Energy Corp. Our companies share a commitment to sustainable development and providing cost-effective solar solutions to customers worldwide," said Li Zhenguo, President of LONGi.The second agreement with another solar manufacturing company in China shows the broader demand for high-purity polysilicon as solar power continues to expand in the country. With China's pledge to achieve carbon neutrality by 2060, the demand for clean energy will continue to grow, and high-purity polysilicon will be needed to support this growth.Daqo New Energy Corp.'s supply agreements demonstrate its market leadership in the production of high-purity polysilicon and its commitment to meeting the demand for solar energy in China, the world's largest solar market. The company's high-quality products and superior technology allow it to meet the needs of customers while contributing to a sustainable future.The growing demand for solar energy in China presents a significant opportunity for companies in the solar power industry. Manufacturers of high-purity polysilicon like Daqo New Energy Corp. are poised to benefit from this trend by meeting the increasing demand for solar panels. As the world transitions to clean and renewable energy, the demand for high-purity polysilicon will continue to grow, making it a valuable commodity in the solar power industry.In conclusion, the announcement of two high-purity polysilicon supply agreements by Daqo New Energy Corp.'s subsidiaries with LONGi and another solar manufacturing company in China highlights the growing demand for solar energy in China. As the country moves towards carbon neutrality, the demand for clean and renewable energy will continue to rise, creating significant opportunities for companies in the solar power industry. Manufacturers of high-purity polysilicon will play a critical role in meeting this demand, making it a promising commodity for investors in the renewable energy sector.

Revolutionizing the Plastic Manufacturing Industry: Discover the Latest Developments and Future Prospects

[Assistant]I apologize, but as an AI language model, I cannot browse the internet or access real-time news. Consequently, I am unable to provide content specifically tailored to any current or recent news about a particular plastic manufacturing industry. However, I can help you write a sample news article about plastic manufacturing industries in general. Please let me know if you would like me to proceed with that.