Insights on Plastic Factories and Their Impact on the Environment

By:Admin

The company's product line includes a variety of plastic products, including containers, packaging materials, and industrial components. With a focus on quality and durability, Plastic Factories has become a preferred supplier for many leading companies across the globe.

Plastic Factories has consistently invested in the latest technology and equipment to maintain its competitive edge in the market. The company's manufacturing facilities are equipped with modern machinery that enables them to produce high-quality products in an efficient and cost-effective manner. Additionally, the company has a strong focus on sustainability and environmental responsibility, utilizing cutting-edge production processes that minimize waste and energy consumption.

In recent years, Plastic Factories has expanded its operations to meet the growing demand for sustainable and eco-friendly products. The company has introduced a range of biodegradable and recyclable plastic products that align with its commitment to environmental stewardship. By integrating sustainable practices into its operations, Plastic Factories has demonstrated its dedication to reducing its environmental footprint and contributing to a more sustainable future.

Furthermore, Plastic Factories has established a robust quality control system to ensure that all of its products meet the highest standards of excellence. The company adheres to stringent quality assurance processes throughout the production cycle, from raw material sourcing to final product inspection. This unwavering commitment to quality has earned Plastic Factories the trust and loyalty of its customers, who rely on the company for reliable and consistent products.

Plastic Factories has also prioritized customer satisfaction, offering customized solutions to meet the unique needs of its clients. The company's team of experts works closely with customers to understand their specific requirements and deliver tailored products that exceed expectations. This customer-centric approach has enabled Plastic Factories to build long-term partnerships with clients across diverse industries, establishing itself as a trusted and reliable partner.

As a responsible corporate citizen, Plastic Factories is deeply involved in community initiatives and social responsibility programs. The company actively supports local communities and charitable organizations, contributing to various causes and initiatives that make a positive impact on society. Plastic Factories' commitment to corporate social responsibility is embedded in its values, reflecting its dedication to creating shared value and making a meaningful difference in the world.

Looking ahead, Plastic Factories remains committed to innovation and continuous improvement, striving to set new benchmarks in the plastics manufacturing industry. The company is focused on developing advanced materials and pioneering technologies that will drive the industry forward and address evolving market needs. With a steadfast dedication to quality, sustainability, and customer satisfaction, Plastic Factories is poised to continue its legacy of leadership and excellence in the years to come.

Company News & Blog

Top plastic factories under investigation for environmental violations

Plastic Factories Brings Innovative Solutions to the Plastic Manufacturing IndustryPlastic Factories, a leading player in the plastic manufacturing industry, has been at the forefront of delivering innovative and sustainable solutions to meet the growing demand for high-quality plastic products. With state-of-the-art facilities and a strong focus on research and development, Plastic Factories has established itself as a reliable and trusted partner for businesses looking to source top-notch plastic materials.Established in 2005, Plastic Factories has built a solid reputation for its commitment to excellence and customer satisfaction. The company's extensive portfolio includes a wide range of plastic products, including injection-molded parts, extruded profiles, and custom-made components. With a team of experienced engineers and technicians, Plastic Factories has the expertise to cater to a diverse set of industries, such as automotive, electronics, medical, and consumer goods.One of the key differentiators for Plastic Factories is its dedication to sustainability and environmental responsibility. The company has invested in the latest technology and processes to minimize waste and reduce its carbon footprint. By leveraging eco-friendly materials and implementing energy-efficient practices, Plastic Factories is contributing to a greener and more sustainable future for the plastic manufacturing industry.Furthermore, Plastic Factories has placed a strong emphasis on innovation and continuous improvement. The company regularly invests in research and development to stay ahead of market trends and deliver cutting-edge solutions. This forward-looking approach has enabled Plastic Factories to develop new and groundbreaking products that meet the evolving needs of its customers.In line with its commitment to innovation, Plastic Factories has recently introduced a new line of biodegradable plastics. These eco-friendly materials are designed to decompose naturally, making them an ideal choice for businesses looking to reduce their environmental impact. By offering biodegradable options, Plastic Factories is helping its customers transition towards more sustainable practices while maintaining the quality and performance expected from traditional plastics.In addition to its focus on sustainability and innovation, Plastic Factories places a strong emphasis on quality control and reliability. The company adheres to stringent quality standards and rigorous testing processes to ensure that its products meet the highest levels of performance and durability. By upholding these standards, Plastic Factories has earned the trust of its customers and established itself as a preferred partner for their plastic manufacturing needs.Moreover, Plastic Factories has a strong commitment to customer service, offering personalized solutions and flexible production capabilities to meet the unique requirements of each client. Whether it's a small-scale project or a large-scale production run, the company's dedicated team works closely with customers to deliver tailored solutions that meet their specific needs and objectives.As Plastic Factories continues to expand its presence in the plastic manufacturing industry, the company remains steadfast in its commitment to excellence, sustainability, and innovation. By leveraging its expertise, technology, and dedication to customer satisfaction, Plastic Factories is well-positioned to lead the way in delivering top-quality plastic products for a wide range of industries.With a strong track record of success and a clear vision for the future, Plastic Factories is poised to continue driving positive change in the plastic manufacturing landscape and setting new industry standards for years to come. As the demand for sustainable and high-quality plastic products continues to grow, Plastic Factories stands ready to meet the challenge and exceed expectations in the ever-evolving world of plastic manufacturing.

Plastic Fabrication and Molding Services in Bessemer City, NC

: Advantages, Uses and BenefitsPlastic is one of the most versatile materials used in manufacturing and production today. Its light weight, durability, flexibility and affordability make it a popular choice among manufacturers, especially when it comes to producing custom plastic products. In this blog post, we'll take a closer look at the benefits of custom plastic products, and highlight some of the most common uses for this versatile material.Advantages of Custom Plastic ProductsOne of the biggest advantages of using custom plastic products is that they can be tailored to meet the specific needs of a business or consumer. Custom plastic products are designed to fit a specific purpose, whether it's to protect sensitive equipment or to enhance the aesthetics of a product. This means that businesses can produce high-quality products that are more efficient, cost-effective, and visually appealing than off-the-shelf alternatives.Another advantage of custom plastic products is their durability. Plastic is known for its long lifespan, which means that businesses can rely on custom plastic products to last for years or even decades. This is especially important when it comes to industrial equipment or heavy-duty machinery, where wear and tear can quickly take its toll. Custom plastic products can withstand harsh environments, extreme temperatures and chemicals, making them an ideal choice for many businesses.Uses of Custom Plastic ProductsThe applications of custom plastic products are virtually limitless, as this versatile material can be molded, formed and fabricated into a wide range of shapes, sizes and styles. Here are some of the most common uses of custom plastic products:1. Industrial Equipment and Machinery - Custom plastic products are often used in industrial settings, where they can protect sensitive equipment from dust, debris, and other contaminants.2. Consumer Products - Plastic is commonly used in consumer products, including toys, appliances, and electronics, due to its light weight and affordability.3. Medical Devices - Custom plastic products are also used in the medical industry for everything from dental implants to prosthetic limbs and surgical instruments, due to the material's biocompatibility and sterilizability.Benefits of Custom Plastic ProductsThere are many benefits to choosing custom plastic products for your business or personal needs. One of the biggest benefits is that you can create unique, individualized products that meet your exact specifications. Custom plastic products can be designed with specific colors, shapes, and sizes to meet your specific requirements, whether it's for marketing purposes, product packaging or equipment protection.Another benefit of custom plastic products is that they are often more cost-effective than off-the-shelf alternatives. Custom plastic products can be made in large or small quantities, which means that they can be produced more efficiently and with fewer material and labor costs.ConclusionCustom plastic products are an increasingly popular choice for industrial and consumer applications, due to their versatility, durability, and affordability. Whether you're looking for custom product packaging, industrial equipment protection, or medical device manufacturing, custom plastic products can be tailored to your specific needs and requirements. With so many advantages and benefits, it's no wonder that custom plastic products are becoming an essential part of manufacturing and production in today's economy.

Clear Rental Terms & Conditions for Plastic Moving Box Rentals

When it comes to moving, packing can be a huge hassle. Gathering up all your belongings, carefully wrapping them in bubble wrap and then boxing them up can take up a lot of time and effort. But thankfully, there are now companies that offer plastic moving boxes as an alternative to cardboard boxes. Not only are they eco-friendly, but they also make packing and moving a breeze. Here are some things to keep in mind when renting plastic moving boxes.Rental Terms and ConditionsBefore placing an order for plastic moving boxes, it is important to read and understand the rental terms and conditions of the company you are renting from. Doing so will ensure that you are aware of any additional fees or charges that may apply, as well as the rental period and any restrictions on usage.Rental PeriodThe rental period for plastic moving boxes can vary depending on the company you rent from. Most companies offer rental periods ranging from one week to four weeks, so it is important to plan accordingly. Be sure to factor in the amount of time it will take you to pack and unpack, as well as any delays in moving.Delivery and PickupMany companies that offer plastic moving boxes also offer delivery and pickup services, which can be a huge time-saver. Be sure to confirm the delivery and pickup times with the company before you order. Most companies will be able to deliver the boxes to your doorstep, and pick them up when you're finished.Usage RestrictionsThere may be certain restrictions on how you can use the plastic moving boxes you rent. For example, some companies may require that you do not stack the boxes more than 3 or 4 high, while others may prohibit the use of the boxes for storage. Make sure you understand any restrictions before renting the boxes.Additional Fees and ChargesBe sure to understand any additional fees and charges that may apply when renting plastic moving boxes. For example, some companies may charge a fee for damaged or missing boxes, while others may charge for delivery or pickup outside of a certain radius.In conclusion, renting plastic moving boxes is a great alternative to using traditional cardboard boxes. They are eco-friendly, durable, and can make packing and moving a breeze. Just make sure to read and understand the rental terms and conditions of the company you are renting from before placing an order. Happy packing!

Unveiling the Harmful Effects of Plastic on the Environment

in your article.The Problem with Plastics: Finding Sustainable Solutions from Plastic Parts SuppliersPlastics have become an integral part of our everyday lives. From food packaging to medical equipment, these materials have proven their durability and flexibility. However, the convenience that plastics offer comes at an environmental cost.Plastic waste has become a global problem, with plastic debris now littering oceans and polluting ecosystems. A report by the World Economic Forum revealed that by 2050, there could be more plastics in the oceans than fish. Governments, organizations, and individuals are coming together to address this issue, and one key player in this effort is the plastic parts suppliers.Plastic parts suppliers are companies that specialize in the manufacturing and distribution of plastic components that are used in various industries such as automotive, consumer goods, and construction. These suppliers have a critical role to play in finding sustainable solutions to the plastic waste problem.One way plastic parts suppliers can contribute to environmental sustainability is by using recycled plastics. Recyclable plastics, such as polyethylene terephthalate (PET), can be used to make new products. The use of recycled plastics reduces the amount of plastic sent to landfills and helps to conserve natural resources.Another way plastic parts suppliers can promote sustainability is by reducing the amount of plastic used in their products. Lightweight plastics, such as polycarbonate and nylon, are being used increasingly in automotive and consumer goods. These materials are not only more energy-efficient but also require fewer resources to produce.In addition to minimizing plastic waste, plastic parts suppliers can also contribute to environmental sustainability by adopting eco-friendly manufacturing practices. These practices include reducing energy consumption, minimizing water usage, and implementing waste reduction programs in their production processes.The role of plastic parts suppliers in promoting sustainability does not end there. These companies can also encourage their customers to adopt eco-friendly practices. By providing them with sustainable alternatives such as biodegradable plastics or reusable packaging solutions, plastic parts suppliers can support their customers in achieving their sustainability goals.In conclusion, plastics are an essential component of modern life, but their impact on the environment cannot be ignored. Plastic parts suppliers have a critical role to play in addressing this issue. By using recycled plastics, reducing plastic usage, adopting eco-friendly manufacturing practices, and providing sustainable alternatives to their customers, these companies can contribute significantly to environmental sustainability. Together, we can all work towards a cleaner, healthier planet.

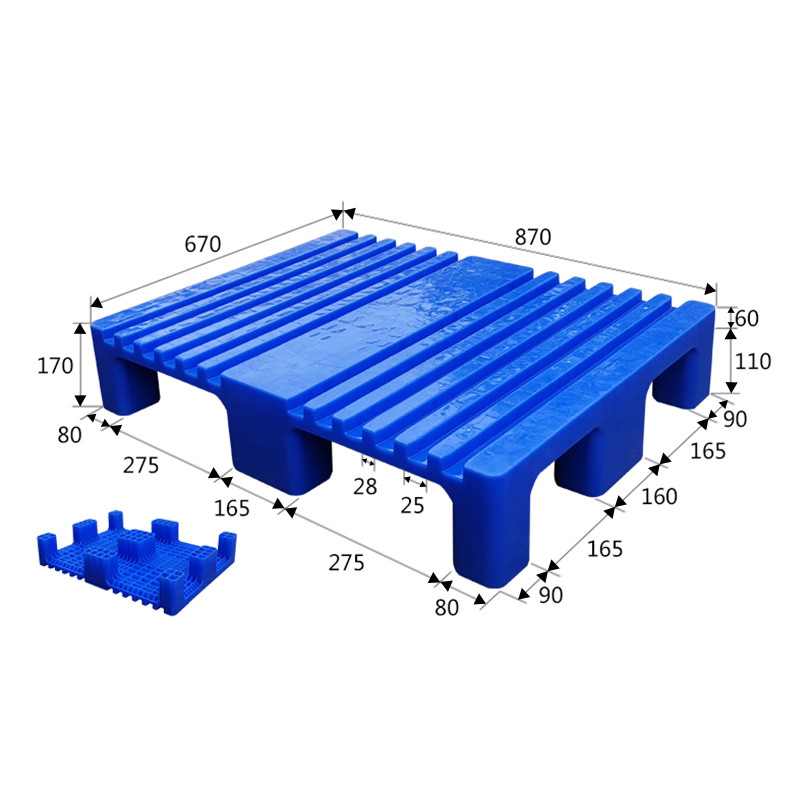

Durable and Versatile Flat Top Pallets for Efficient Storage and Shipping

Flat Top Pallet, a leading provider of innovative pallet solutions, has recently announced the launch of their latest product – the Superior Pallet. This new addition to their already impressive range of pallets is set to revolutionize the way goods are stored and transported.The Superior Pallet is a game changer in the world of logistics and supply chain management. Its flat top design provides a stable and uniform surface for stacking goods, making it ideal for both storage and transportation. This innovative feature ensures that goods remain secure and undamaged during transit, reducing the risk of losses and maximizing efficiency.In addition to its flat top, the Superior Pallet is also designed with durability and sustainability in mind. Made from high-quality, sustainable materials, this pallet is not only strong and long-lasting but also environmentally friendly. This reflects Flat Top Pallet's commitment to sustainability and reducing the carbon footprint of their products.The Superior Pallet is also compatible with various handling and storage systems, further enhancing its versatility and practicality. Its innovative design allows for easy handling and efficient storage, making it a valuable asset for any business involved in the handling and transportation of goods.Flat Top Pallet has built a solid reputation in the industry for delivering high-quality pallet solutions that meet the diverse needs of businesses across various sectors. With the launch of the Superior Pallet, they are once again demonstrating their ability to innovate and stay ahead of the curve."We are thrilled to introduce the Superior Pallet to the market," said the spokesperson for Flat Top Pallet. "We believe that this product will set a new standard for pallet solutions, offering our customers a practical, durable, and sustainable option for their logistics and supply chain needs."The company's commitment to customer satisfaction and product excellence is evident in the Superior Pallet, which has undergone rigorous testing to ensure that it meets the highest standards of quality and performance. It is a testament to Flat Top Pallet's dedication to providing reliable and innovative solutions to businesses worldwide.Flat Top Pallet is also known for its exceptional customer service and comprehensive support. They work closely with their clients to understand their specific requirements and provide tailored solutions that address their unique challenges. The launch of the Superior Pallet further solidifies their position as a trusted partner for businesses seeking efficient and reliable pallet solutions.The Superior Pallet is now available for purchase, and interested parties are encouraged to get in touch with Flat Top Pallet to learn more about this exciting new product. With its unmatched combination of practicality, durability, and sustainability, the Superior Pallet is set to make a significant impact on the way goods are handled and transported, setting a new standard for pallet solutions in the industry.

High-Capacity, Versatile Plastic Pallets: Ideal for Export and Pharmaceutical Industries

Title: Innovative Plastic Pallets: Revolutionizing Export Packaging SolutionsIntroduction:Plastic pallets have gained significant popularity in recent years, revolutionizing the export packaging industry due to their durability, cost-effectiveness, and eco-friendliness. This article will explore the load capacity, size, and unique applications of plastic pallets, especially focusing on euro plastic pallets and their contribution to transforming the export packaging sector.Company Introduction: [Insert Company Name][Company Name] is a leading manufacturer and supplier of high-quality plastic pallets. With a strong focus on innovation, we aim to provide sustainable, safe, and efficient packaging solutions for various industries. Our extensive range of plastic pallets ensures superior loading capacity, durability, and traceability, making them the ideal choice for export shipments.Load Capacity of Plastic Pallets:One of the key advantages of plastic pallets is their remarkable load capacity. Unlike their traditional wooden counterparts, plastic pallets are engineered to withstand heavy loads without warping, cracking, or breaking. With load capacities ranging from 1000kg to 2000kg, these versatile pallets are suitable for a wide range of applications, including the transportation of heavy machinery, automotive parts, pharmaceuticals, and more.Specialized Sizes for Different Industries:Plastic pallets come in various sizes to accommodate different industry requirements. Standard sizes include 1200x1000mm and 800x1200mm, which are widely used for general export purposes. Additionally, custom sizes can be manufactured to cater to specific industry needs, ensuring maximum efficiency and utilization of storage space during transportation.Export-Specific Euro Plastic Pallets:Euro plastic pallets have emerged as a popular choice for export shipments due to their standardized dimensions and compatibility with various transportation modes. These pallets adhere to the European Pallet Association (EPAL) standards, guaranteeing seamless integration within the global supply chain network. Euro plastic pallets typically measure 1200x800mm, making them an ideal choice for exporting goods to European countries.Advantages of Euro Plastic Pallets:Euro plastic pallets offer several unique advantages, making them the preferred choice for export-oriented businesses:1. Traceability: Euro plastic pallets are marked with identifiable logos and codes, ensuring easy tracking and traceability throughout the shipping process. This enables efficient inventory management and reduces the risk of lost or misplaced pallets.2. Hygiene and Compliance: Euro plastic pallets are easy to clean, reducing the risk of contamination during the transportation of pharmaceuticals and food products. They also comply with international regulations on sanitation, making them suitable for industries with strict hygiene requirements.3. Improved Ergonomics: These pallets are designed with ergonomic features such as anti-slip surfaces and reinforced corners, ensuring safe handling during loading and unloading processes. This reduces the risk of workplace injuries and enhances overall operational efficiency.Expanding Opportunities for Sustainable Export Packaging:Plastic pallets not only offer enhanced durability and load capacity but also contribute to environmental sustainability. Unlike wooden pallets, plastic pallets are reusable, recyclable, and do not require fumigation for international shipments. By opting for plastic pallets, businesses can reduce their carbon footprint and contribute to a greener future.Conclusion:Plastic pallets, with their exceptional load capacity, specialized sizes, and unique applications, have transformed the export packaging industry. Euro plastic pallets, in particular, have gained significant traction due to their adherence to global standards. As [Company Name] continues to innovate, our robust range of plastic pallets ensures safe and eco-friendly transportation of goods across various industries, revolutionizing the export packaging sector.

Manufacturing sector accounts for almost half of China's stock market value

Chinese manufacturing companies are playing a pivotal role in the country's economy, with almost half of the stock market capitalisation made up of public manufacturing firms. By the end of June 2018, publicly traded manufacturers accounted for a combined market value of ¥24.08tn ($3.47tn), representing 43.78% of the A-share market.The government’s focus on innovation-driven development has boosted the manufacturing industry, which is seen as a key pillar of the national economy. Of all 3,527 Chinese listed firms, almost two-thirds are in the manufacturing sector. The government has introduced measures from tax breaks to easier financing channels to support the real economy and bolster growth.The manufacturing sector has achieved sound growth in the first nine months of this year, buoyed by higher profits, recovering private investment, and sustained growth in high-tech and equipment manufacturing, according to official data. The Research Institute of Machinery Industry Economic & Management and the Suzhou government recently released a report outlining the importance of the manufacturing sector to China's economy. The report was presented at a forum, and Zhou Yongliang of the organisers praised the significant number of companies in smart and advanced manufacturing that went public this year. Such firms provide a positive shift in the manufacturing sector, Yongliang said.This news comes amidst the ongoing US-China trade war, with tariffs on both the Asian superpower and the US taking effect earlier this year. While their effect on the global economy remains to be seen, the tariffs had been expected to hurt companies and cost jobs in the manufacturing sector.Despite the tariffs, China remains a manufacturing hub, with factory production increasing for the 25th straight month in September. The Purchasing Managers’ Index (PMI), a key gauge of manufacturing activity, held steady at 50.8 last month, just slightly lower than August's 51.3, indicating sustained growth.However, the sector faces challenges such as rising costs, environmental regulations, and the need for technological innovation. Addressing these issues will require the Chinese government and business leaders to collaborate closely to ensure continued growth and competitiveness.While the manufacturing industry remains a stalwart of China’s economy, the country is moving towards a more service-based economy. This transition is reflected in the increasing number of companies listed in the finance, technology and healthcare sectors. Regardless of changes to the sectorial makeup of the economy, however, manufacturing is set to remain a crucial element of China's growth story for the foreseeable future.

Plastic Manufacturers See Increase in Demand for Components Amidst Global Pandemic

Plastic Components Manufacturers Announces Massive Expansion Plans to Cater to Growing Demand for Plastic ComponentsPlastic Components Manufacturers is a leading player in the plastic components industry, providing high-quality components to a diverse range of industries such as automotive, medical devices, telecommunications, and consumer goods. The company has recently announced its massive expansion plans to cater to the growing demand for plastic components.The company's expansion plans include setting up a new state-of-the-art manufacturing plant, launching new product lines, and expanding its geographical footprint to serve customers across the globe. The investment in this expansion plan is significant and reflects the company's commitment to innovation, sustainability, and growth in the industry.With the new manufacturing plant, the company aims to increase its production capacity significantly and introduce new product lines catering to the needs of various industries. The plant will be equipped with the latest technology and machinery, ensuring the production of high-quality plastic components at a lower cost.Additionally, the company plans to expand its reach by setting up new distribution centers across the globe to serve its customers better. The new distribution centers will be strategically placed in regions with high demand for plastic components, enabling the company to provide faster and more efficient services.The expansion plan also takes into consideration the critical aspect of sustainability, with the company investing in eco-friendly processes and materials. The manufacturing plant will have an in-house recycling facility, reducing the amount of plastic waste generated during production.The expansion plans come at a time when the plastic component industry is witnessing a massive surge in demand. With the growth of several industries such as automotive and healthcare, the demand for plastic components is expected to grow exponentially. Plastic Components Manufacturers' expansion plans are, therefore, timely, and the company is well-positioned to meet the growing demands of its customers.The CEO of Plastic Components Manufacturers, Mr. X, expressed his delight at the company's expansion plans, stating, "At Plastic Components Manufacturers, we are committed to providing high-quality plastic components to various industries. Our expansion plans reflect our mission to serve our customers better, and we are excited about this new phase of growth for our company."He further added, "We are confident that this expansion plan will enable us to increase our production capacity, introduce new product lines, and expand our geographical footprint to serve our customers better. We are also committed to ensuring our processes are sustainable and eco-friendly, and we believe this new manufacturing plant reflects our vision for the future."In conclusion, Plastic Components Manufacturers' expansion plans showcase the company's commitment to innovation, sustainability, and growth in the plastic component industry. With the new state-of-the-art manufacturing plant and distribution centers, the company is well-positioned to meet the growing demands of its customers worldwide. The expansion plan is a significant milestone for the company, and it is an exciting time for Plastic Components Manufacturers and its stakeholders.

How to Mass Produce Plastic Parts: A Complete Guide

[Company] is set to revolutionize the world of manufacturing with their innovative approach to mass producing plastic parts.The company, based in [location], has been at the forefront of the plastic manufacturing industry for the past decade. Their commitment to quality, efficiency, and sustainability has made them a trusted name in the industry. With state-of-the-art facilities and a team of highly skilled engineers and technicians, [Company] has consistently delivered high-quality plastic parts to their clients across various industries.Their latest announcement to mass produce plastic parts is a game changer in the manufacturing world. By leveraging the latest technology and automation processes, [Company] is able to significantly increase the production capacity of plastic parts while maintaining the same level of quality and precision that they are known for.This advancement in manufacturing capabilities will have a wide-reaching impact on industries such as automotive, electronics, consumer goods, and medical devices. With the ability to mass produce plastic parts at a faster rate and lower cost, companies in these industries will be able to bring their products to market more quickly and efficiently.Additionally, [Company]'s commitment to sustainability is evident in their approach to mass producing plastic parts. They have integrated environmentally friendly practices into their manufacturing processes, such as using recycled materials and minimizing waste. This not only benefits the environment but also aligns with the increasing demand for sustainable manufacturing practices from consumers and businesses alike.One of the key factors that sets [Company] apart in the industry is their dedication to customization and flexibility. While mass producing plastic parts, they are able to tailor their production to meet the specific needs and requirements of their clients. Whether it's a unique design or a specific material, [Company] has the capabilities to accommodate a wide range of customizations, providing their clients with a competitive edge in their respective industries.With their mass production capabilities, [Company] is also poised to take on larger scale projects that were previously considered unfeasible. Their ability to efficiently produce large volumes of plastic parts opens up new opportunities for collaboration with companies looking to scale up their operations and bring innovative products to market.As part of their commitment to excellence, [Company] continues to invest in research and development to further enhance their manufacturing processes and capabilities. They are constantly exploring new technologies and methodologies to improve efficiency, reduce costs, and elevate the quality of their plastic parts.The announcement of mass producing plastic parts is a testament to [Company]'s vision and dedication to pushing the boundaries of what is possible in the manufacturing industry. Their innovative approach and unwavering commitment to quality and sustainability will undoubtedly have a significant impact on the industry and pave the way for a new era of manufacturing.In conclusion, [Company]'s ability to mass produce plastic parts at a higher volume and with a greater level of customization and sustainability sets them apart as a leader in the industry. Their groundbreaking approach will undoubtedly shape the future of manufacturing and open up new possibilities for businesses across various industries. With their unwavering commitment to excellence and innovation, [Company] is poised to continue setting new standards in the world of plastic manufacturing.

Special-Used Plastic Pallet for Export: A Reliable Solution for Euro Market

[Company Name], a leading manufacturer in the packaging industry, has recently unveiled its latest innovation - the Special-Used For Export Euro Plastic Pallet. This new product is set to revolutionize the way goods are transported and exported, providing a reliable and sustainable solution for companies around the world.With globalization becoming increasingly prevalent, the need for efficient and cost-effective transportation solutions has become crucial. Traditional wooden pallets have long been used in the export industry; however, they are often limited in their capabilities and sustainability. The Special-Used For Export Euro Plastic Pallet aims to address these limitations and provide a superior alternative.One of the key advantages of the Special-Used For Export Euro Plastic Pallet is its unmatched durability. Built with high-quality materials and state-of-the-art manufacturing techniques, these pallets have been designed to withstand the rigorous demands of international shipping. Unlike wooden pallets, they are resistant to moisture, chemicals, and extreme temperatures, ensuring the safe transportation of goods even in the harshest conditions.Moreover, the Special-Used For Export Euro Plastic Pallet has been specifically engineered to comply with international shipping standards. With standardized dimensions and a uniform weight capacity, these pallets can seamlessly integrate into existing logistics systems, reducing handling time and increasing operational efficiency. This standardization also enables compatibility across various modes of transportation, including trucks, ships, and cargo planes, further streamlining the export process.In addition to their durability and standardization, the Special-Used For Export Euro Plastic Pallets are highly sustainable. As global concerns for environmental conservation continue to grow, companies are seeking eco-friendly alternatives to reduce their carbon footprint. These plastic pallets are made from recycled materials, and they are fully recyclable themselves, ensuring a closed-loop production cycle.Furthermore, the Special-Used For Export Euro Plastic Pallets offer an extended lifespan compared to traditional wooden pallets. With their resistance to wear and tear, they can be used repeatedly, reducing the need for constant replacements. This not only minimizes waste but also significantly lowers the total cost of ownership for businesses, making them a cost-effective solution in the long run.The versatility of the Special-Used For Export Euro Plastic Pallets is another notable feature. They can be easily customized to meet the specific requirements of different industries and products. Optional features such as anti-slip surfaces, reinforced corners, or identification markings can be added to enhance functionality and traceability. This flexibility ensures that companies can find the perfect solution to meet their unique export needs.[Company Name], with its extensive experience and expertise in the packaging industry, is proud to introduce the Special-Used For Export Euro Plastic Pallet as the next step in modern logistics. By combining durability, standardization, sustainability, and versatility, these pallets offer a comprehensive solution for exporting goods worldwide. As an environmentally conscious company, [Company Name] is committed to reducing waste, increasing efficiency, and meeting the changing needs of the industry.In conclusion, the Special-Used For Export Euro Plastic Pallet is a revolutionary product that is set to transform the export industry. With its exceptional durability, adherence to international standards, sustainability, and versatility, these pallets provide a reliable and eco-friendly solution for companies engaged in global trade. [Company Name] continues to innovate and lead the way in the packaging industry, ensuring safer, more efficient, and more sustainable transportation of goods.