Discover the Leading Manufacturer of Plexiglass: Unraveling the Industry's Giant

By:Admin

Introduction:

In recent years, the demand for transparent acrylic solutions has witnessed a significant growth owing to their versatility and durability. As a result, the biggest plexiglass company (brand name removed) has emerged as the premier manufacturer and supplier of these materials. With a committed focus on innovation and quality, {brand name} has garnered a reputation for producing cutting-edge solutions that cater to a diverse range of industries.

Company Overview:

Established in {year}, {brand name} has steadily grown to become a global leader in the manufacture of transparent acrylic solutions. The company's success can be attributed to its unwavering dedication to delivering excellence in their products and services. With state-of-the-art manufacturing facilities and a team of skilled professionals, {brand name} consistently pushes the boundaries of what is possible with acrylic.

Product Range and Expertise:

{Brand name}'s extensive product range covers various applications, including architecture, retail, automotive, marine, and many more. Their offerings include:

1. Architectural Solutions:

{Brand name} understands the importance of aesthetic appeal in architectural designs and offers a wide selection of transparent acrylic solutions. From windows and skylights to partitions and canopies, their products combine functionality and stunning visual impact, providing architects and designers with immense creative freedom.

2. Retail Solutions:

Recognizing the growing need for visually appealing displays, {brand name} provides solutions that enhance the visual merchandising experience. Their range of merchandising racks, display cases, and signage options are created with precision to elevate product visibility and brand identity.

3. Automotive Solutions:

In the automotive industry, {brand name} is known for its high-quality acrylic materials used in sunroofs, side windows, and headlight lenses. Their transparent solutions offer exceptional clarity and UV resistance, ensuring safety and an enhanced experience for drivers and passengers alike.

4. Marine Solutions:

Given the unique challenges faced by the marine industry, {brand name} has developed specialized transparent acrylic products that are resistant to saltwater, UV rays, and extreme weather conditions. These include windows, shields, and deck hatches that enhance both comfort and safety for marine vessels.

5. Customized Solutions:

One of {brand name}'s main strengths lies in their ability to collaboratively develop tailored solutions for their clients' specific needs. Through their efficient design and production process, they offer personalized transparent acrylic solutions to various industries, such as aviation, electronic displays, medical equipment, and more.

Commitment to Sustainability:

In addition to its commitment to quality, {brand name} places great importance on sustainable production practices. They continuously invest in research and development to reduce their environmental impact. With a focus on recycling and minimizing waste, they strive to ensure that the production and use of their acrylic solutions promote a greener future.

Future Endeavors and Global Reach:

With a robust infrastructure and an ever-growing customer base, {brand name} aims to further expand its global presence. The company has a strong commitment to research and development, continuously innovating to meet the evolving needs of its customers and stay at the forefront of the industry. {Brand name} is committed to forging long-term partnerships with its clients, offering unrivaled customer service, and ensuring premium quality transparent acrylic solutions worldwide.

Conclusion:

As the demand for transparent acrylic solutions continues to rise, {brand name} remains at the forefront, consistently delivering top-notch products catered to various industries. With their expertise, commitment to quality, and focus on sustainability, the company is well-positioned for continued growth and success. With the ability to customize solutions and a dedication to addressing the challenges faced by different industries, {brand name} is truly the leading manufacturer in the transparent acrylic industry.

Company News & Blog

Discover the Leading Manufacturer of Plexiglass: Unraveling the Industry's Giant

Title: Leading Manufacturer of High-Quality Transparent Acrylic Solutions, Company IntroductionIntroduction:In recent years, the demand for transparent acrylic solutions has witnessed a significant growth owing to their versatility and durability. As a result, the biggest plexiglass company (brand name removed) has emerged as the premier manufacturer and supplier of these materials. With a committed focus on innovation and quality, {brand name} has garnered a reputation for producing cutting-edge solutions that cater to a diverse range of industries.Company Overview:Established in {year}, {brand name} has steadily grown to become a global leader in the manufacture of transparent acrylic solutions. The company's success can be attributed to its unwavering dedication to delivering excellence in their products and services. With state-of-the-art manufacturing facilities and a team of skilled professionals, {brand name} consistently pushes the boundaries of what is possible with acrylic.Product Range and Expertise:{Brand name}'s extensive product range covers various applications, including architecture, retail, automotive, marine, and many more. Their offerings include:1. Architectural Solutions:{Brand name} understands the importance of aesthetic appeal in architectural designs and offers a wide selection of transparent acrylic solutions. From windows and skylights to partitions and canopies, their products combine functionality and stunning visual impact, providing architects and designers with immense creative freedom.2. Retail Solutions:Recognizing the growing need for visually appealing displays, {brand name} provides solutions that enhance the visual merchandising experience. Their range of merchandising racks, display cases, and signage options are created with precision to elevate product visibility and brand identity.3. Automotive Solutions:In the automotive industry, {brand name} is known for its high-quality acrylic materials used in sunroofs, side windows, and headlight lenses. Their transparent solutions offer exceptional clarity and UV resistance, ensuring safety and an enhanced experience for drivers and passengers alike.4. Marine Solutions:Given the unique challenges faced by the marine industry, {brand name} has developed specialized transparent acrylic products that are resistant to saltwater, UV rays, and extreme weather conditions. These include windows, shields, and deck hatches that enhance both comfort and safety for marine vessels.5. Customized Solutions:One of {brand name}'s main strengths lies in their ability to collaboratively develop tailored solutions for their clients' specific needs. Through their efficient design and production process, they offer personalized transparent acrylic solutions to various industries, such as aviation, electronic displays, medical equipment, and more.Commitment to Sustainability:In addition to its commitment to quality, {brand name} places great importance on sustainable production practices. They continuously invest in research and development to reduce their environmental impact. With a focus on recycling and minimizing waste, they strive to ensure that the production and use of their acrylic solutions promote a greener future.Future Endeavors and Global Reach:With a robust infrastructure and an ever-growing customer base, {brand name} aims to further expand its global presence. The company has a strong commitment to research and development, continuously innovating to meet the evolving needs of its customers and stay at the forefront of the industry. {Brand name} is committed to forging long-term partnerships with its clients, offering unrivaled customer service, and ensuring premium quality transparent acrylic solutions worldwide.Conclusion:As the demand for transparent acrylic solutions continues to rise, {brand name} remains at the forefront, consistently delivering top-notch products catered to various industries. With their expertise, commitment to quality, and focus on sustainability, the company is well-positioned for continued growth and success. With the ability to customize solutions and a dedication to addressing the challenges faced by different industries, {brand name} is truly the leading manufacturer in the transparent acrylic industry.

Two Chinese Solar Manufacturing Companies Sign High-Purity Polysilicon Supply Agreements

High-Purity Polysilicon Supply Agreements: Signaling the Growing Demand for Solar Energy in ChinaThe global demand for clean and renewable energy has been increasing rapidly in recent years, and solar power is one of the most promising sources of renewable energy. China, known as the world's largest solar panel manufacturer and consumer, has made remarkable strides in promoting and expanding its solar power industry. This trend is evidenced by the announcement of two high-purity polysilicon supply agreements by Daqo New Energy Corp.'s subsidiaries, one with LONGi and another solar manufacturing company in China.Polysilicon is a key component in the manufacturing of solar panels, and high-purity polysilicon is necessary for the production of high-efficiency solar cells. Daqo New Energy Corp. is a leading producer of high-purity polysilicon, and its subsidiaries' agreements with LONGi and another solar manufacturing company in China signify the growing demand for solar energy in China.LONGi is the world's largest solar wafer manufacturer, and its partnership with Daqo New Energy Corp. is expected to strengthen its supply chain and meet the increasing demand for solar products. "We are pleased to strengthen our strategic partnership with Daqo New Energy Corp. Our companies share a commitment to sustainable development and providing cost-effective solar solutions to customers worldwide," said Li Zhenguo, President of LONGi.The second agreement with another solar manufacturing company in China shows the broader demand for high-purity polysilicon as solar power continues to expand in the country. With China's pledge to achieve carbon neutrality by 2060, the demand for clean energy will continue to grow, and high-purity polysilicon will be needed to support this growth.Daqo New Energy Corp.'s supply agreements demonstrate its market leadership in the production of high-purity polysilicon and its commitment to meeting the demand for solar energy in China, the world's largest solar market. The company's high-quality products and superior technology allow it to meet the needs of customers while contributing to a sustainable future.The growing demand for solar energy in China presents a significant opportunity for companies in the solar power industry. Manufacturers of high-purity polysilicon like Daqo New Energy Corp. are poised to benefit from this trend by meeting the increasing demand for solar panels. As the world transitions to clean and renewable energy, the demand for high-purity polysilicon will continue to grow, making it a valuable commodity in the solar power industry.In conclusion, the announcement of two high-purity polysilicon supply agreements by Daqo New Energy Corp.'s subsidiaries with LONGi and another solar manufacturing company in China highlights the growing demand for solar energy in China. As the country moves towards carbon neutrality, the demand for clean and renewable energy will continue to rise, creating significant opportunities for companies in the solar power industry. Manufacturers of high-purity polysilicon will play a critical role in meeting this demand, making it a promising commodity for investors in the renewable energy sector.

Plastic manufacturing industry has potential to double employment and reduce import dependence: Minister Piyush Goyal

Plastic Industry Process: Understanding the Key FactorsThe plastic industry is one of the biggest contributors to the Indian economy. With an anticipated turnover of Rs 10 trillion in the next five years, the plastic manufacturing industry has huge potential for growth. In addition to generating immense employment opportunities, it can also help reduce the country’s import dependence. To achieve this goal, it is crucial to understand the plastic industry process and the critical factors that impact it.Plastic manufacturing starts with the collection of raw materials, which can be either virgin or recycled plastics. The first step in the process is polymerization, where monomers are joined together to form a polymer. This is followed by compounding, where additives such as colorants and stabilizers are added to the polymer to improve its properties. The third step is processing, including extrusion, injection molding, and blow molding, among others. Finally, the product is decorated, assembled, and packaged for shipment.The plastic industry process is influenced by many factors, including technology, raw materials, equipment, and regulations. The use of advanced technologies has revolutionized the plastic manufacturing industry, enabling it to produce high-quality and efficient products. Automation has also played a significant role in simplifying the manufacturing process, reducing costs, and improving efficiency.Another critical factor that impacts the plastic industry process is raw materials. The plastic manufacturing industry in India is dependent on imports for many of its raw materials. To reduce this dependence, the government has initiated several programs to promote the use of recycled plastics, which can significantly reduce the industry's carbon footprint.Equipment is another crucial factor in the plastic industry process. The right equipment can help optimize the manufacturing process and improve the quality of the final product. In India, the government has been providing subsidies and tax incentives to encourage the use of advanced manufacturing equipment. This has helped small and medium-scale industries improve their manufacturing processes, making them more competitive in the global market.Regulations are also a critical factor that impacts the plastic industry process. The government has implemented several regulations to mitigate the harmful effects of plastic on the environment. For instance, the government banned single-use plastic in the country, and it has been actively promoting sustainable manufacturing practices. This has encouraged the industry to adopt eco-friendly practices that align with the government's vision.In conclusion, the plastic industry process is complex and dependent on various factors. Understanding these factors is key to optimizing the process, reducing costs, and improving the quality of the final product. With the government's support, the plastic manufacturing industry has great potential to grow and contribute significantly to the Indian economy. It is critical to keep pace with global trends, technological advancements, and eco-friendly practices to remain competitive and sustainable.

Top Tips for Effective Pallet Management in Facilities Development and Operations

If you are involved in the logistics industry, then you must be familiar with pallets. Pallets are flat structures that are used as a base for stacking and transporting goods. They are one of the most essential components of modern warehousing and transportation. In this blog, we will talk about the importance of pallets and the role they play in facilities development and operations.Moving PalletsMoving pallets can be a daunting task, especially if you don't have the right equipment. A pallet jack or a forklift is required to move pallets around the warehouse. Additionally, moving pallets can be dangerous if the operator is not properly trained. Therefore, it is essential to ensure that your staff is trained and equipped to move pallets safely.Facilities DevelopmentFacilities development is one of the most critical aspects of the logistics industry. The organization of a warehouse or distribution center directly affects operational efficiency and profitability. When designing a warehouse, the question of pallet storage is a crucial consideration. A well-designed warehouse should be able to accommodate pallet racking systems that maximize storage space. Additionally, the layout of the warehouse should ensure that pallets are easily accessible to the operators.OperationsOperations are another critical aspect of the logistics industry that can be improved with pallets. The use of pallets in the warehouse significantly reduces material handling time. With the use of pallets, operators can easily load and unload goods from transportation vehicles, reducing the time required to move goods. Additionally, stacking pallets provides an efficient use of warehouse space.The use of pallets can also result in reduced damage to goods during transportation. Stacked pallets can provide a barrier between the goods and the vehicle's floor, reducing the likelihood of damage.ConclusionIn conclusion, pallets play a crucial role in facilities development and operations. The logistics industry heavily relies on pallets as a means of efficient storage and transportation. The use of pallets can provide numerous benefits, such as improved operational efficiency, increased safety, and reduced damage to goods. When designing a warehouse or distribution center, it is crucial to consider pallet storage and accessibility. In addition, it is vital to ensure that staff is appropriately trained to move pallets safely. Overall, pallets are an essential component of the logistics industry that cannot be overlooked.

New study reveals alarming levels of microplastic contamination in plastic parts

Plastic Parts Expands its Services in the Manufacturing IndustryPlastic Parts, a leading manufacturer of injection-molded plastic parts, is expanding its services to cater to the growing demands of the manufacturing industry. The company has been in the business for over 30 years and has developed a reputation for providing high-quality plastic parts to various industries. With the expansion, Plastic Parts aims to offer its clients a more comprehensive range of manufacturing solutions.The expansion includes the acquisition of state-of-the-art machinery and equipment, as well as the integration of advanced manufacturing techniques into its processes. The company has invested heavily in research and development to come up with innovative solutions that can meet the evolving needs of its clients. The expansion also involves the hiring of additional personnel, including engineers, technicians, and operators, to support the new services."We are thrilled to announce the expansion of our services, which is a testament to our commitment to providing our clients with the best manufacturing solutions possible," said the company's spokesperson. "With the newly acquired machinery and the integration of advanced manufacturing technologies, we are confident that we can provide our clients with faster turnaround times, improved product quality, and competitive pricing."Plastic Parts provides a wide range of manufacturing services, including custom plastic injection molding, overmolding, insert molding, and rapid prototyping. With the expansion, the company is now offering additional services that include CNC machining, 3D printing, and assembly and packaging services. The new services will enable Plastic Parts to offer a one-stop-shop solution for its clients, thus saving them time and costs associated with working with multiple manufacturers.CNC machining is a process that involves the use of computer-controlled machines to produce precise parts from a variety of materials, including plastics, metals, and composites. Plastic Parts' CNC machining services offer high precision and tight tolerances, making it suitable for producing complex parts with intricate geometries. The company's CNC machines are equipped with the latest software technology that allows for efficient and accurate production.3D printing, on the other hand, is a process that involves creating a physical object from a digital design file. The technology has been rapidly evolving over the years, and Plastic Parts has invested in the latest 3D printing technology to offer its clients the most advanced solutions available. The company's 3D printing services cater to clients who require small volumes of parts or who need to produce prototypes quickly.Assembly and packaging services are also a new addition to Plastic Parts' portfolio. The company's assembly services involve the integration of various components to create a finished product, while its packaging services involve the design and production of custom packaging that protects the product during shipping and storage. The services are designed to provide a complete end-to-end solution for clients who want to focus on their core business and leave the manufacturing to experts.Plastic Parts' expansion is timely, given the growing demand for high-quality manufacturing solutions. The company's new services will enable it to expand its reach to new markets and offer its existing clients a more comprehensive range of solutions. With its team of experienced engineers and technicians and its state-of-the-art facilities, Plastic Parts is well-positioned to meet the needs of its clients and stay ahead of the competition.In conclusion, Plastic Parts' expansion is a significant milestone in the company's journey to become a leader in the manufacturing industry. With the new services, the company is poised to provide its clients with faster turnaround times, improved quality, and competitive pricing. The expansion also demonstrates Plastic Parts' commitment to innovation and excellence and its focus on staying ahead of the curve. As the manufacturing industry continues to evolve, Plastic Parts is well-prepared to meet the challenges and seize the opportunities that come its way.

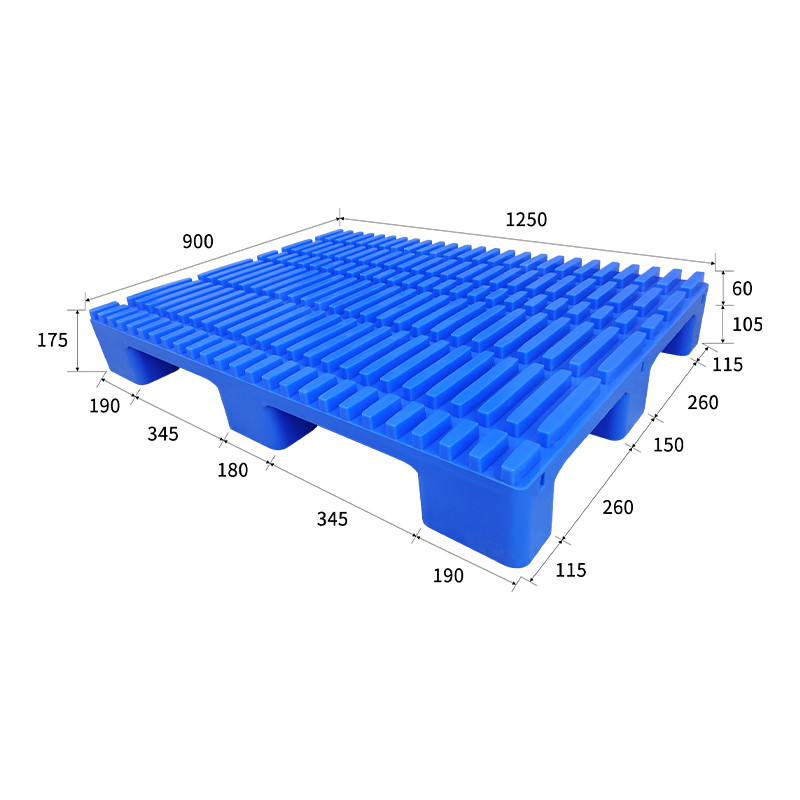

High-Capacity, Versatile Plastic Pallets: Ideal for Export and Pharmaceutical Industries

Title: Innovative Plastic Pallets: Revolutionizing Export Packaging SolutionsIntroduction:Plastic pallets have gained significant popularity in recent years, revolutionizing the export packaging industry due to their durability, cost-effectiveness, and eco-friendliness. This article will explore the load capacity, size, and unique applications of plastic pallets, especially focusing on euro plastic pallets and their contribution to transforming the export packaging sector.Company Introduction: [Insert Company Name][Company Name] is a leading manufacturer and supplier of high-quality plastic pallets. With a strong focus on innovation, we aim to provide sustainable, safe, and efficient packaging solutions for various industries. Our extensive range of plastic pallets ensures superior loading capacity, durability, and traceability, making them the ideal choice for export shipments.Load Capacity of Plastic Pallets:One of the key advantages of plastic pallets is their remarkable load capacity. Unlike their traditional wooden counterparts, plastic pallets are engineered to withstand heavy loads without warping, cracking, or breaking. With load capacities ranging from 1000kg to 2000kg, these versatile pallets are suitable for a wide range of applications, including the transportation of heavy machinery, automotive parts, pharmaceuticals, and more.Specialized Sizes for Different Industries:Plastic pallets come in various sizes to accommodate different industry requirements. Standard sizes include 1200x1000mm and 800x1200mm, which are widely used for general export purposes. Additionally, custom sizes can be manufactured to cater to specific industry needs, ensuring maximum efficiency and utilization of storage space during transportation.Export-Specific Euro Plastic Pallets:Euro plastic pallets have emerged as a popular choice for export shipments due to their standardized dimensions and compatibility with various transportation modes. These pallets adhere to the European Pallet Association (EPAL) standards, guaranteeing seamless integration within the global supply chain network. Euro plastic pallets typically measure 1200x800mm, making them an ideal choice for exporting goods to European countries.Advantages of Euro Plastic Pallets:Euro plastic pallets offer several unique advantages, making them the preferred choice for export-oriented businesses:1. Traceability: Euro plastic pallets are marked with identifiable logos and codes, ensuring easy tracking and traceability throughout the shipping process. This enables efficient inventory management and reduces the risk of lost or misplaced pallets.2. Hygiene and Compliance: Euro plastic pallets are easy to clean, reducing the risk of contamination during the transportation of pharmaceuticals and food products. They also comply with international regulations on sanitation, making them suitable for industries with strict hygiene requirements.3. Improved Ergonomics: These pallets are designed with ergonomic features such as anti-slip surfaces and reinforced corners, ensuring safe handling during loading and unloading processes. This reduces the risk of workplace injuries and enhances overall operational efficiency.Expanding Opportunities for Sustainable Export Packaging:Plastic pallets not only offer enhanced durability and load capacity but also contribute to environmental sustainability. Unlike wooden pallets, plastic pallets are reusable, recyclable, and do not require fumigation for international shipments. By opting for plastic pallets, businesses can reduce their carbon footprint and contribute to a greener future.Conclusion:Plastic pallets, with their exceptional load capacity, specialized sizes, and unique applications, have transformed the export packaging industry. Euro plastic pallets, in particular, have gained significant traction due to their adherence to global standards. As [Company Name] continues to innovate, our robust range of plastic pallets ensures safe and eco-friendly transportation of goods across various industries, revolutionizing the export packaging sector.

Plastic Pallets for Sale - Heavy Duty Industrial Used & New Bulk Skids | Affordable Lightweight and Durable Options Available

Title: Revolutionizing Industrial Logistics: Used Plastic Pallets for Sale at Unbeatable PricesIntroduction:In today's fast-paced industrial environment, efficiency and cost-effectiveness are key factors for businesses seeking success. With logistic operations being the backbone of numerous industries, the need for durable and reliable pallets cannot be overstated. Container Exchanger, a leading provider of used plastic pallets, is offering a game-changing solution for businesses by delivering lightweight and heavy-duty plastic pallets at unbeatable prices.Saving Money without Compromising Quality:Container Exchanger understands the challenges faced by businesses operating in industries such as warehousing, manufacturing, food processing, and retail, where pallets play a crucial role in streamlining operations. Recognizing the potential economic benefits of purchasing used plastic pallets without compromising on quality, they have become an industry leader offering affordable solutions that meet the increasing demands of a dynamic business environment.Unmatched Variety and Durability:Container Exchanger prides itself on offering a wide range of new and used plastic pallets that cater to the specific needs of various industries. Whether businesses require lightweight pallets for reduced shipping costs or heavy-duty pallets to withstand demanding loads, Container Exchanger provides a diverse selection suitable for all applications.Their extensive inventory of used plastic pallets is meticulously inspected and certified before being made available for sale, ensuring top-notch quality and longevity. By offering both new and used options, Container Exchanger accommodates businesses with varying budget constraints, providing immense cost savings without sacrificing durability and performance.Sustainability and Environmental Responsibility:Plastic pallets, being reusable and recyclable, are an eco-friendly alternative to traditional wood pallets. Container Exchanger's commitment to sustainability is evident in their emphasis on promoting the use of used plastic pallets. By reviving and repurposing pallets that have already been used, they contribute to reducing waste in landfills while minimizing the environmental footprint associated with manufacturing new pallets.Not only do businesses benefit from a cost-effective solution, but they also contribute to a greener future by choosing used plastic pallets. This is a win-win situation for companies seeking sustainability initiatives and cost reductions, while also aligning with their corporate social responsibility goals.Meeting the Unique Demands of Industrial Operations:Container Exchanger understands the nuances and specific requirements of various industries. Through their vast network of sellers nationwide, they ensure that businesses can access used plastic pallets suitable for nearly every industry, including pharmaceuticals, automotive, beverages, and more.With a focus on industrial-strength pallets, Container Exchanger ensures that their products can withstand the rigors of daily operations, including transportation, storage, and stacking. Their used plastic pallets offer exceptional strength, resistance to impact, and longevity, thereby reducing costly product damage and enhancing overall productivity.Unbeatable Pricing and Customer Support:Container Exchanger's commitment to customer satisfaction goes beyond providing cost-effective solutions. With a transparent pricing model and the lowest prices available on the market, they empower businesses to make smart investment choices whilst never compromising on quality.Additionally, their knowledgeable team of professionals is readily available to assist customers in selecting the most suitable pallets for their specific requirements. With years of industry experience, Container Exchanger's experts offer valuable insights and recommendations to ensure businesses make informed decisions that positively impact their operations.Conclusion:Container Exchanger's dedication to revolutionizing industrial logistics through their range of used plastic pallets provides businesses with a cost-effective, durable, and environmentally responsible solution. By addressing the varying needs of different industries and offering unbeatable pricing, they have established themselves as a trusted partner for businesses looking to optimize their supply chain operations.Embracing sustainability, while simultaneously reducing costs and enhancing operational efficiency, has never been easier. With Container Exchanger's lightweight and heavy-duty plastic pallets for sale, businesses can truly unlock substantial savings while contributing to a greener future.

Durable Plastic Storage Boxes with Secure Handles and Stackable Design - Perfect for Home, Garden, and Garage Use

Storage, Strata Heavy Duty Storage Boxes, and Durable Storage Boxes.Organizing your home, garage, or garden can be a real headache. You need reliable storage containers that can withstand wear and tear, and keep your belongings safe and secure. Strata's Heavy Duty Storage Boxes are the perfect solution for all your storage needs. These boxes are made from high-quality durable plastic, ensuring that they last for years to come.One of the key features of Strata's Heavy Duty Storage Boxes is their robustness and hard-wearing construction. They are designed to withstand heavy use, making them ideal for use in any environment. Whether you're storing tools in your garage, or keeping your garden supplies organized, these boxes are up to the task.Another great feature of these storage boxes is their strong yellow clip lock handles. The handles ensure that the box stays securely closed, protecting your belongings from damage or loss. You can stack these boxes too, making them ideal for small spaces. When the lids are attached, they also provide a compact storage solution that's easy to move around.Strata's Heavy Duty Storage Boxes are fully nestable, allowing you to save space when you're not using them. You can easily store them away until you need them again, without taking up too much space. Additionally, these boxes can be padlocked or cable-tied closed, providing extra security for your belongings.Overall, Strata's Heavy Duty Storage Boxes are the perfect solution for anyone looking for durable and reliable storage containers. Whether you're a homeowner, gardener, or DIY enthusiast, these boxes are sure to meet your needs. So, if you're looking for Heavy Duty Plastic Container Storage, Strata Heavy Duty Storage Boxes, or Durable Storage Boxes, then look no further than Strata's Heavy Duty Storage Boxes.

Plastic Fabrication Companies: How to Choose the Right Manufacturer for Your Needs

Title: Emerging Trends in Plastic Fabrication Industry Pave the Way for Future GrowthIntroduction: Plastic fabrication is an integral part of numerous industries, ranging from construction and automotive to healthcare and packaging. The demand for high-quality plastic products has necessitated the development of reliable and innovative plastic fabrication companies. In this article, we will explore the latest trends in the plastic fabrication industry and their impact on the overall growth of the sector.I. Technological Advancements Boost Efficiency and Precision In recent years, plastic fabrication companies have embraced technological advancements to streamline their manufacturing processes. Advanced computer numerical control (CNC) machines enable precise and efficient cutting, shaping, and molding of plastic materials. These machines, combined with powerful simulation software, have revolutionized the design and production phases. With reduced production times and improved accuracy, plastic fabrication companies are able to meet the evolving needs of their clients.II. Focus on Sustainable Practices and MaterialsThe growing concern for the environment has contributed to a shift in the practices and materials used by plastic fabrication companies. Increasingly, companies are adopting sustainable manufacturing practices such as recycling and reusing plastic waste generated during the fabrication process. Moreover, there is a growing preference for biodegradable and plant-based plastics as alternatives to traditional petroleum-based plastics. This shift towards sustainable practices not only aligns with environmental goals but also enhances the overall brand image of plastic fabrication companies.III. Customization and Design FlexibilityOne of the key trends in the plastic fabrication industry is the growing demand for custom-designed plastic products. Plastic fabrication companies are investing in design capabilities to cater to unique client requirements. With advancements in computer-aided design (CAD) software, these companies can work closely with clients to bring their concepts to life. Customization and design flexibility have allowed plastic fabrication companies to address diverse needs across industries, giving them a competitive edge in the market.IV. Automating Assembly ProcessesAutomation and robotics are making their way into the plastic fabrication industry, offering increased efficiency and improved quality control. Automated assembly processes enable faster production cycles, reduce labor costs, and help minimize errors. Robotic systems are capable of handling complex tasks such as precise gluing, welding, and fastening, resulting in higher-quality end products. By embracing automation, plastic fabrication companies can optimize their operations to meet the ever-growing demand for plastic products.V. Collaboration and PartnershipsTo stay competitive in the dynamic plastic fabrication industry, companies are forging strategic partnerships and collaborations. Collaboration with material suppliers, component manufacturers, and industry experts enables companies to access specialized knowledge and resources. Joint efforts to develop innovative technologies and materials accelerate the pace of progress within the industry. These partnerships not only foster growth but also facilitate knowledge exchange and continuous improvement.Conclusion:The plastic fabrication industry is witnessing significant transformation as companies adopt new technologies, sustainable practices, and innovative design techniques. Technological advancements have increased efficiency and precision, enabling plastic fabrication companies to cater to diverse client requirements. Collaboration and partnerships have also played a crucial role in driving innovation and fostering growth. Moreover, the industry's commitment to sustainability is propelling the development of eco-friendly materials and practices. As the demand for plastic products continues to rise, plastic fabrication companies are well-positioned to leverage these trends and drive future growth.

Discover the Benefits of Personalized Plastic Products for Your Business

Custom Plastic Parts: The Advantages of Plastic Over Other MaterialsWhen it comes to manufacturing custom parts, plastic has emerged as a popular choice for many industries due to its versatility, durability, and affordability. In recent years, plastic has become a go-to material for custom parts, due in part to the advancements in injection molding technology and a wider variety of available plastics. So why should you consider using custom plastic parts for your next project? Here are a few of the advantages that make plastic a standout option:1. VersatilityPlastic is an incredibly versatile material that has the ability to be molded into nearly any shape or size, making it an ideal choice for custom parts. With the advances in injection molding technology, it is easy to create complex shapes, varying thicknesses, and intricate details with precision. This versatility allows for a wide range of applications for custom plastic parts in various industries, including medical devices, electronics, automotive, and consumer goods.2. DurabilityAnother significant advantage of plastic is its durability. Unlike materials such as metal, plastic is resistant to corrosion, which is vital for parts that come into contact with chemicals or harsh environments. Plastic is also resistant to impact, shock, and vibration, making it an excellent choice for parts that are exposed to challenging conditions. Additionally, plastic parts can withstand extreme temperatures, making them ideal for use in both heat-sensitive and cold-sensitive applications.3. AffordabilityCost is an essential factor when it comes to manufacturing custom parts, and plastic is often a more cost-effective option compared to other materials. The cost of manufacturing custom plastic parts is lower than metal parts, for example, due to the cheaper raw material cost and easier production process, leading to reduced production time and cost. Additionally, plastic has a lower weight than metal, contributing to lower transportation and shipping expenses.4. CustomizationCustom plastic parts offer a high level of customization, allowing for a wide range of colors, finishes, and textures. With injection molding, it is easy to add graphics, logos, and other branding elements directly to the parts during production. Customization is even more important for parts used in consumer goods industries that require aesthetic appeal, as custom parts can give the product a unique look and feel that competitors cannot replicate.5. SustainabilityFinally, plastic is also a sustainable material, as it is recyclable and can be reused for other purposes. There are eco-friendly plastics available in the market that are made from plant-based, renewable resources. These materials are biodegradable and compostable, making them an excellent option for companies that prioritize sustainability in their manufacturing process.ConclusionIf you are looking for a cost-effective, durable, versatile, and customizable material for your custom parts, then plastic is a viable option. Advances in injection molding technology, coupled with a wide range of available plastics, have made custom plastic parts a popular choice for various industries. Whether you need a small, intricate part or a large, complex assembly, custom plastic parts offer a lot of advantages. If you want to explore the world of custom plastic parts, get in touch with a trusted manufacturer today.