Top Slotted Pallets: The Ultimate Guide to Logistics and Warehouse Efficiency

By:Admin

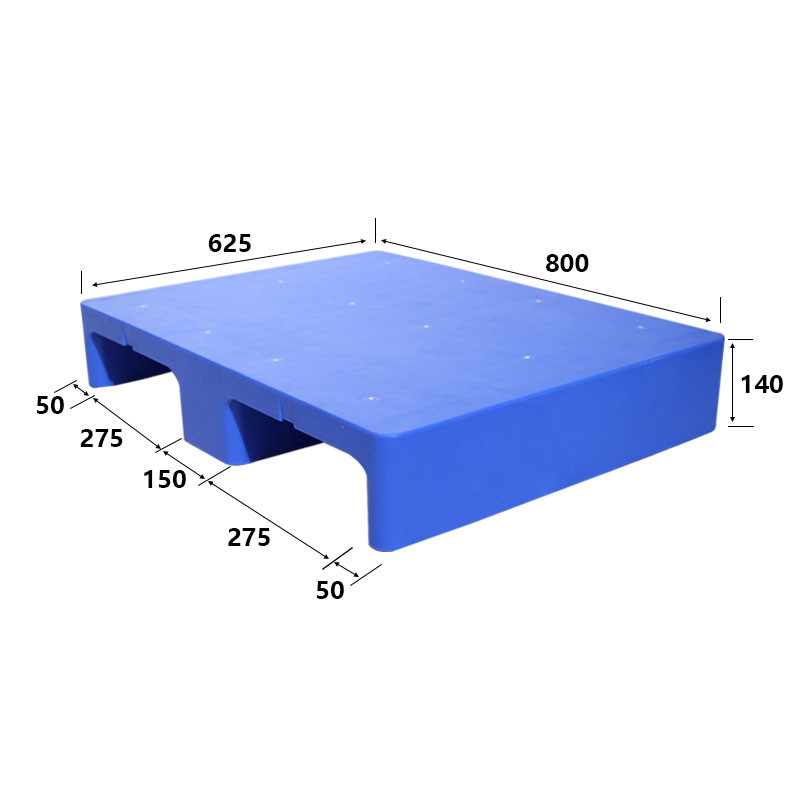

The Logistics Slotted Top Pallet is constructed using high-quality, durable materials and features a slotted top deck that allows for easy loading and unloading of goods. The slotted design also ensures optimal airflow, making it ideal for the storage of perishable goods. Additionally, the pallet’s reinforced structure enables it to withstand heavy loads and the rigors of daily use, making it a reliable and long-lasting solution for material handling needs.

This new pallet is part of [Company Name]’s commitment to providing innovative and efficient solutions for optimizing warehouse and distribution center operations. With a focus on maximizing space utilization and improving workflow efficiency, [Company Name] continues to develop products that address the evolving needs of the industry.

The Logistics Slotted Top Pallet is compatible with various material handling equipment, including forklifts, pallet jacks, and conveyor systems. This versatility makes it a practical and adaptable solution for a wide range of material handling applications. Whether used for storing goods in warehouses or for transporting items within a distribution center, the Logistics Slotted Top Pallet offers a reliable and convenient solution for optimizing material handling processes.

In addition to its functional design, the Logistics Slotted Top Pallet is also constructed with sustainability in mind. Made from recyclable materials, this pallet is an environmentally friendly option for companies looking to minimize their carbon footprint. By choosing the Logistics Slotted Top Pallet, businesses can align their material handling operations with their sustainability goals and contribute to a more environmentally conscious supply chain.

To further support its customers, [Company Name] offers customizable options for the Logistics Slotted Top Pallet, allowing businesses to tailor the pallet to their specific requirements. Whether it’s custom dimensions, load capacity, or color preferences, [Company Name] works closely with its clients to deliver pallet solutions that meet their unique needs.

As a leader in the material handling industry, [Company Name] is dedicated to delivering products that combine functionality, durability, and sustainability. The introduction of the Logistics Slotted Top Pallet exemplifies the company’s commitment to innovation and its ability to provide practical solutions that drive operational excellence for its customers.

With the Logistics Slotted Top Pallet, [Company Name] continues to uphold its reputation as a trusted provider of high-quality material handling solutions. As the industry evolves and demands for efficient, sustainable solutions grow, [Company Name] remains at the forefront, continuously developing products that set new standards for material handling efficiency and performance.

In conclusion, the introduction of the Logistics Slotted Top Pallet reinforces [Company Name]’s position as a leader in the material handling industry. With its focus on functionality, durability, and sustainability, the Logistics Slotted Top Pallet is a valuable addition to [Company Name]’s product range, offering businesses a reliable and efficient solution for their material handling needs. As the industry continues to evolve, [Company Name] remains dedicated to providing innovative products that drive operational excellence and support the success of its customers.

Company News & Blog

Plastic manufacturing industry has potential to double employment and reduce import dependence: Minister Piyush Goyal

Plastic Industry Process: Understanding the Key FactorsThe plastic industry is one of the biggest contributors to the Indian economy. With an anticipated turnover of Rs 10 trillion in the next five years, the plastic manufacturing industry has huge potential for growth. In addition to generating immense employment opportunities, it can also help reduce the country’s import dependence. To achieve this goal, it is crucial to understand the plastic industry process and the critical factors that impact it.Plastic manufacturing starts with the collection of raw materials, which can be either virgin or recycled plastics. The first step in the process is polymerization, where monomers are joined together to form a polymer. This is followed by compounding, where additives such as colorants and stabilizers are added to the polymer to improve its properties. The third step is processing, including extrusion, injection molding, and blow molding, among others. Finally, the product is decorated, assembled, and packaged for shipment.The plastic industry process is influenced by many factors, including technology, raw materials, equipment, and regulations. The use of advanced technologies has revolutionized the plastic manufacturing industry, enabling it to produce high-quality and efficient products. Automation has also played a significant role in simplifying the manufacturing process, reducing costs, and improving efficiency.Another critical factor that impacts the plastic industry process is raw materials. The plastic manufacturing industry in India is dependent on imports for many of its raw materials. To reduce this dependence, the government has initiated several programs to promote the use of recycled plastics, which can significantly reduce the industry's carbon footprint.Equipment is another crucial factor in the plastic industry process. The right equipment can help optimize the manufacturing process and improve the quality of the final product. In India, the government has been providing subsidies and tax incentives to encourage the use of advanced manufacturing equipment. This has helped small and medium-scale industries improve their manufacturing processes, making them more competitive in the global market.Regulations are also a critical factor that impacts the plastic industry process. The government has implemented several regulations to mitigate the harmful effects of plastic on the environment. For instance, the government banned single-use plastic in the country, and it has been actively promoting sustainable manufacturing practices. This has encouraged the industry to adopt eco-friendly practices that align with the government's vision.In conclusion, the plastic industry process is complex and dependent on various factors. Understanding these factors is key to optimizing the process, reducing costs, and improving the quality of the final product. With the government's support, the plastic manufacturing industry has great potential to grow and contribute significantly to the Indian economy. It is critical to keep pace with global trends, technological advancements, and eco-friendly practices to remain competitive and sustainable.

Plastic Fabrication and Molding Services in Bessemer City, NC

: Advantages, Uses and BenefitsPlastic is one of the most versatile materials used in manufacturing and production today. Its light weight, durability, flexibility and affordability make it a popular choice among manufacturers, especially when it comes to producing custom plastic products. In this blog post, we'll take a closer look at the benefits of custom plastic products, and highlight some of the most common uses for this versatile material.Advantages of Custom Plastic ProductsOne of the biggest advantages of using custom plastic products is that they can be tailored to meet the specific needs of a business or consumer. Custom plastic products are designed to fit a specific purpose, whether it's to protect sensitive equipment or to enhance the aesthetics of a product. This means that businesses can produce high-quality products that are more efficient, cost-effective, and visually appealing than off-the-shelf alternatives.Another advantage of custom plastic products is their durability. Plastic is known for its long lifespan, which means that businesses can rely on custom plastic products to last for years or even decades. This is especially important when it comes to industrial equipment or heavy-duty machinery, where wear and tear can quickly take its toll. Custom plastic products can withstand harsh environments, extreme temperatures and chemicals, making them an ideal choice for many businesses.Uses of Custom Plastic ProductsThe applications of custom plastic products are virtually limitless, as this versatile material can be molded, formed and fabricated into a wide range of shapes, sizes and styles. Here are some of the most common uses of custom plastic products:1. Industrial Equipment and Machinery - Custom plastic products are often used in industrial settings, where they can protect sensitive equipment from dust, debris, and other contaminants.2. Consumer Products - Plastic is commonly used in consumer products, including toys, appliances, and electronics, due to its light weight and affordability.3. Medical Devices - Custom plastic products are also used in the medical industry for everything from dental implants to prosthetic limbs and surgical instruments, due to the material's biocompatibility and sterilizability.Benefits of Custom Plastic ProductsThere are many benefits to choosing custom plastic products for your business or personal needs. One of the biggest benefits is that you can create unique, individualized products that meet your exact specifications. Custom plastic products can be designed with specific colors, shapes, and sizes to meet your specific requirements, whether it's for marketing purposes, product packaging or equipment protection.Another benefit of custom plastic products is that they are often more cost-effective than off-the-shelf alternatives. Custom plastic products can be made in large or small quantities, which means that they can be produced more efficiently and with fewer material and labor costs.ConclusionCustom plastic products are an increasingly popular choice for industrial and consumer applications, due to their versatility, durability, and affordability. Whether you're looking for custom product packaging, industrial equipment protection, or medical device manufacturing, custom plastic products can be tailored to your specific needs and requirements. With so many advantages and benefits, it's no wonder that custom plastic products are becoming an essential part of manufacturing and production in today's economy.

Automated Machines for Manufacturing Plastic Products

Machines To Make Plastic Products Expand [Company Name]’s Production Capabilities[Company Name] is a leading manufacturer in the plastic industry, specializing in the production of a wide range of plastic products for various industries. With a focus on innovation and advanced technology, [Company Name] is constantly investing in new equipment to improve its production capabilities and meet the growing demand for high-quality plastic products.The latest addition to [Company Name]’s production facilities is the introduction of cutting-edge machines to make plastic products. These state-of-the-art machines are designed to enhance the company’s manufacturing processes and increase its production capacity, allowing for the efficient production of a wider range of plastic products. With the installation of these machines, [Company Name] is set to further solidify its position as a leading provider of quality plastic products in the market.The new machines boast advanced features that enable precise and efficient manufacturing processes. Equipped with the latest technology, including computer-aided design and automated production capabilities, these machines are capable of producing complex plastic products with intricate designs and specifications. Additionally, the machines are designed to optimize the use of raw materials, reducing waste and increasing overall production efficiency.The investment in these machines is in line with [Company Name]’s commitment to quality and innovation. By leveraging the latest technology in plastic manufacturing, [Company Name] aims to offer its customers a wider range of high-quality plastic products that meet their specific requirements. The company is dedicated to maintaining the highest standards of excellence in its manufacturing processes, and the introduction of these new machines is a testament to that commitment.Moreover, with the addition of these advanced machines, [Company Name] is poised to expand its product offerings and enter new markets. The enhanced production capabilities will enable the company to cater to the evolving needs of various industries, including automotive, packaging, construction, and consumer goods. By diversifying its product portfolio, [Company Name] aims to further strengthen its position as a preferred supplier of plastic products in the global market.In addition to the expansion of its production capabilities, [Company Name] is also focused on sustainability and environmental responsibility. The new machines are designed to minimize the environmental impact of plastic production by optimizing energy usage and reducing waste. By adopting sustainable manufacturing practices, [Company Name] is committed to reducing its carbon footprint and contributing to a more sustainable future.The introduction of the new machines to make plastic products marks a significant milestone for [Company Name]. With a continued focus on innovation, quality, and sustainability, the company is well-positioned to meet the evolving needs of the market and maintain its leadership in the plastic industry. As [Company Name] continues to invest in advanced technology and manufacturing capabilities, its commitment to excellence remains unwavering, ensuring that its customers receive the highest quality plastic products for their diverse applications.

5 Benefits of Using Reusable Collapsible Crates for Farmers and Retailers

Folding Vegetable Crates Revolutionizing the Food IndustryFolding Vegetable Crates (FVC) have revolutionized the way the food industry transports and stores its products. These lightweight, foldable, and durable crates have become a go-to for many companies worldwide, cutting costs and making logistics easier than ever before.FVC, a company that specializes in producing these crates, was founded in 2011, with the goal to make transportation of goods more efficient and eco-friendly. The company's founders, who come from a background in agricultural logistics, saw the need for a crate that would be easy to handle, fold, and store when not in use, and FVC was born.The idea was simple, but the execution was groundbreaking. With advanced technology, FVC now produces high-quality plastic crates that are strong enough to hold heavy loads of produce and can be easily folded and stacked when not in use. This innovative design saves businesses money and storage space, making it an ideal choice for the food industry.The traditional wooden crates that were used in the past were bulky and heavy, which made transportation and storage a challenge. Moreover, they deteriorated over time, requiring frequent repairs and replacement, which added to the cost. FVC comes in handy, and that's why it's regarded as an eco-friendly option because of its reusability. FVC made of polypropylene represents the ideal solution. The crates hold a considerable weight, even when stacked on top of one another, and they are durable, easy to clean and sanitize. FVC crates are available in a variety of sizes, making them adaptable to various types of produce and companies' needs. They are water-resistant and can be safely used in harsh weather conditions, whether it's hot or cold. This feature means they can be used to load or store ice or products that require refrigeration without damage. The folding Vegetable crates are easy to fold and can be stacked in as little as one-third of the space of a traditional crate. This means companies can warehouse more product in a smaller space, freeing up storage room, and optimizing use of space. The space saved is always critical, especially in restaurants and supermarkets, where space is limited.The Folding Vegetable Crates save businesses money by cutting the cost of buying wooden crates, which are costly to replace and repair regularly. Plastic is also cheaper than metal, and with the long lifespan of the FVC crates, they are an affordable investment for any food business looking to cut costs and utilizes its resources well.FVC has become the go-to option for many companies worldwide, and their products have received high praise for their efficiency, durability, and convenience. FVC has made a remarkable impact on the food industry, producing an innovative solution to a problem that many companies have struggled with for years.With over ten years of experience producing high-quality vegetable crates, FVC has become a well-established and reputable company in their field. The company's commitment to innovation, customer satisfaction, and sustainability has earned them a loyal customer base worldwide.FVC has changed the food industry forever with its revolutionary folding vegetable crates. Almost all players in the industry now recognize that using FVC has become an excellent way to reduce storage and transportation costs while also promoting sustainability. The future of the food industry depends on innovative solutions like FVC that are eco-friendly, adaptable, and cost-efficient.

Best Ways to Store and Transport Tobacco Pallets

Tobacco Pallet Company Revolutionizing the Tobacco IndustryIn recent years, the tobacco industry has seen a shift in packaging and transportation methods, largely due to the innovative solutions provided by Tobacco Pallet Company. This cutting-edge company has been at the forefront of revolutionizing the way tobacco products are handled and moved, providing efficient and sustainable solutions for tobacco manufacturers and distributors.Tobacco Pallet Company, based in the United States, has been a key player in the tobacco industry for over a decade. The company specializes in providing high-quality, sustainable pallets specifically designed for the transportation and distribution of tobacco products. By focusing on the unique needs of the tobacco industry, Tobacco Pallet Company has been able to develop innovative solutions that address the challenges faced by manufacturers and distributors in this sector.The company's pallets are designed to be durable, lightweight, and environmentally friendly, making them the ideal choice for the transportation of delicate tobacco products. In addition to their durability and sustainability, the pallets are also designed to optimize space, allowing for more efficient shipping and storage.One of the key advantages of Tobacco Pallet Company's pallets is their ability to withstand the rigorous demands of the tobacco industry. With strict regulations and quality control measures in place, it is essential for tobacco products to be transported and stored in a manner that ensures their integrity and freshness. The company's pallets are specifically designed to meet these requirements, providing a reliable and secure solution for the transportation of tobacco products.Moreover, Tobacco Pallet Company is committed to sustainability and environmental responsibility. The company's pallets are made from recycled materials, reducing their carbon footprint and contributing to a more sustainable supply chain for the tobacco industry. This commitment to sustainability has not gone unnoticed, as more and more tobacco manufacturers and distributors are seeking out Tobacco Pallet Company's solutions for their packaging and transportation needs.In addition to its innovative pallet solutions, Tobacco Pallet Company also offers a range of services to support the needs of the tobacco industry. From custom pallet design to efficient logistics management, the company works closely with its clients to ensure that their specific requirements are met. This personalized approach has garnered the company a reputation for excellence and reliability within the industry.As the tobacco industry continues to evolve, the demand for innovative and sustainable packaging and transportation solutions has never been greater. With its commitment to quality, sustainability, and customer satisfaction, Tobacco Pallet Company is well-positioned to meet these growing demands and continue to drive innovation in the industry.Through its dedication to providing cutting-edge solutions and unparalleled service, Tobacco Pallet Company has established itself as a leader in the tobacco industry. As the company looks to the future, it remains focused on developing new and innovative solutions that will further revolutionize the way tobacco products are handled and transported.In conclusion, Tobacco Pallet Company is a pioneering force in the tobacco industry, providing innovative, sustainable, and reliable solutions for the packaging and transportation of tobacco products. With its commitment to quality, sustainability, and customer satisfaction, the company is poised to continue driving innovation and setting new standards for the industry.

Affordable and Durable Moving Boxes for All Your Packing Needs

[Brand Name Removed] Introduces New and Improved Large Moving Boxes for Hassle-Free Relocations[date], [location] - With an aim to revolutionize the moving experience for individuals and businesses alike, [Brand Name Removed], a renowned provider of packaging solutions, is proud to announce the launch of their latest innovation - the all-new Large Moving Boxes. These boxes are set to revolutionize the way people pack and move, ensuring a hassle-free and organized relocation process.Moving can be a stressful and chaotic experience, with the safety of belongings and efficient packing being of paramount importance. [Brand Name Removed] understands these challenges and has developed the Large Moving Boxes as a game-changer in the industry. Made from premium quality materials, these boxes are sturdy, durable, and designed to handle even the heaviest items without compromising on safety.Measuring [dimensions], each of these Large Moving Boxes provides ample space for packing a variety of household and office items, enabling customers to streamline their relocation process. The boxes are also equipped with ergonomic handles, making them easy to carry and transport, reducing the risk of accidents or injuries during the move."One of our key priorities at [Brand Name Removed] has always been to simplify the moving experience for our customers," said [spokesperson], [title] at [Brand Name Removed]. "Our new and improved Large Moving Boxes are a reflection of that commitment. We have meticulously designed these boxes to cater to all packing needs, ensuring that our customers have a convenient and stress-free moving experience."To further enhance the convenience factor, [Brand Name Removed] has introduced unique features that set their Large Moving Boxes apart in the market. Each box comes with a secure closure system, including flaps and locks that ensure items stay in place during transit, minimizing the risk of damage. Additionally, the boxes are stackable, maximizing efficiency when it comes to both packing and unpacking.The eco-conscious choice is also an essential aspect of [Brand Name Removed]'s ethos. These Large Moving Boxes are made from 100% recycled and recyclable materials, emphasizing the company's commitment to sustainability. By opting for [Brand Name Removed]'s Large Moving Boxes, customers contribute to reducing their carbon footprint and promote a more environmentally friendly approach to moving.In addition to being an excellent solution for residential moves, these Large Moving Boxes are also designed to cater to the needs of businesses. Whether it's an office relocation, a retail store inventory transfer, or a company-wide move, [Brand Name Removed]'s boxes can accommodate a wide range of items, ensuring a smooth and systematic transition.To further support their customers in their moving journey, [Brand Name Removed] offers a comprehensive range of packaging supplies complementing the Large Moving Boxes. From bubble wrap and packing paper to tape and markers, customers can find everything they need under one roof, simplifying the process and saving both time and effort."We understand that moving is not just about boxes. It's about a range of packaging supplies that work cohesively to ensure a seamless experience," added [spokesperson]. "By providing our customers with a one-stop solution, we aim to make the moving process as easy and stress-free as possible."[Brand Name Removed] has added the Large Moving Boxes to their existing line of products, offering customers a versatile range of packaging solutions aimed at meeting their diverse needs. The company's commitment to customer satisfaction, quality, and sustainability has earned them a reputation as a leading provider in the industry.Whether it's a local move or a long-distance relocation, [Brand Name Removed]'s Large Moving Boxes are here to simplify and enhance the moving experience. With their innovative design and commitment to customer needs, [Brand Name Removed] ensures that every move becomes a step towards a more organized and efficient future.About [Brand Name Removed]:[Brand Name Removed] is a recognized provider of packaging solutions, specializing in innovative and eco-friendly products. With a dedication to designing high-quality and sustainable packaging materials, [Brand Name Removed] aims to deliver excellent customer service and make the moving experience hassle-free for individuals and businesses alike.

Massive Plastic Corporation Dominates Global Market

Title: Global Plastic Giant Propels Innovations Amidst Sustainability DriveIntroduction:In a bid to revolutionize the plastic industry and address the growing concerns of sustainability, the world's largest plastic company (Company X) continues to pave the way with groundbreaking advancements and initiatives. With a steadfast commitment to environmentally responsible practices, Company X seeks to promote a circular economy, reduce plastic waste, and prioritize the development of sustainable alternatives. This article explores the company's recent achievements, future goals, and its proactive approach towards shaping a greener future.Sustainable Practices and Innovations:Driven by a vision to mitigate the ecological impact of plastic manufacturing, Company X has implemented several sustainable practices and innovations. One notable initiative is the company's efforts to reduce its carbon footprint by transitioning to renewable energy sources. By investing in wind and solar energy, Company X aims to significantly decrease greenhouse gas emissions throughout its manufacturing processes.Furthermore, the company is undergoing a major transformation by prioritizing the use of recycled materials in their products. Through extensive research and development, Company X has successfully introduced innovative techniques that allow for the incorporation of recycled plastic into its manufacturing lines. This groundbreaking approach not only reduces the demand for virgin plastic but also diverts a substantial amount of plastic waste from entering landfills and oceans.Investing in Sustainable Alternatives:Recognizing the urgency to transition away from traditional plastic products, Company X is actively investing in the development of sustainable alternatives. The company has allocated significant resources towards the research and production of biodegradable and compostable plastics. These eco-friendly alternatives are designed to break down naturally, mitigating the long-lasting environmental impact caused by conventional plastics.Additionally, Company X has strategically partnered with leading research institutions and startups to explore innovative materials such as plant-based polymers and bio-plastics. By embracing these emerging technologies, the company aims to create an entire range of sustainable products that offer consumers a guilt-free choice for their everyday needs.Collaboration and Engagement:In a bid to drive collective change within the industry, Company X actively collaborates with governments, NGOs, and local communities. By fostering partnerships, the company seeks to influence policymakers towards implementing more sustainable regulations and encourage widespread adoption of eco-friendly practices.Moreover, Company X consistently engages with consumers by raising awareness about the importance of reducing plastic waste and encouraging responsible consumption. Through educational campaigns and community outreach programs, the company aims to empower individuals to make mindful choices and actively participate in the global effort to combat plastic pollution.Future Goals and Global Impact:As a global leader in plastic manufacturing, Company X understands its responsibility in spearheading sustainable solutions. Beyond its current initiatives, the company has set ambitious long-term goals, including the complete elimination of single-use plastics from its product line within the next decade.Looking beyond its own operations, Company X aims to inspire change across the entire plastics industry. By openly sharing its research and development findings, as well as collaborating with other companies, the company endeavors to foster an environment of knowledge sharing and cooperation, accelerating the global transition towards a more sustainable future.Conclusion:As the world's largest plastic company, Company X continues to make significant strides in revolutionizing the plastic industry towards a more sustainable and environmentally conscious future. By adopting innovative technologies, investing in sustainable alternatives, and encouraging collaboration, the company is demonstrating its commitment to reducing plastic waste and driving change globally. Through its proactive approach and determined efforts, Company X stands as a beacon of hope in redefining the plastic industry, paving the way for a more sustainable and responsible tomorrow.

How to Mass Produce Plastic Parts: A Complete Guide

[Company] is set to revolutionize the world of manufacturing with their innovative approach to mass producing plastic parts.The company, based in [location], has been at the forefront of the plastic manufacturing industry for the past decade. Their commitment to quality, efficiency, and sustainability has made them a trusted name in the industry. With state-of-the-art facilities and a team of highly skilled engineers and technicians, [Company] has consistently delivered high-quality plastic parts to their clients across various industries.Their latest announcement to mass produce plastic parts is a game changer in the manufacturing world. By leveraging the latest technology and automation processes, [Company] is able to significantly increase the production capacity of plastic parts while maintaining the same level of quality and precision that they are known for.This advancement in manufacturing capabilities will have a wide-reaching impact on industries such as automotive, electronics, consumer goods, and medical devices. With the ability to mass produce plastic parts at a faster rate and lower cost, companies in these industries will be able to bring their products to market more quickly and efficiently.Additionally, [Company]'s commitment to sustainability is evident in their approach to mass producing plastic parts. They have integrated environmentally friendly practices into their manufacturing processes, such as using recycled materials and minimizing waste. This not only benefits the environment but also aligns with the increasing demand for sustainable manufacturing practices from consumers and businesses alike.One of the key factors that sets [Company] apart in the industry is their dedication to customization and flexibility. While mass producing plastic parts, they are able to tailor their production to meet the specific needs and requirements of their clients. Whether it's a unique design or a specific material, [Company] has the capabilities to accommodate a wide range of customizations, providing their clients with a competitive edge in their respective industries.With their mass production capabilities, [Company] is also poised to take on larger scale projects that were previously considered unfeasible. Their ability to efficiently produce large volumes of plastic parts opens up new opportunities for collaboration with companies looking to scale up their operations and bring innovative products to market.As part of their commitment to excellence, [Company] continues to invest in research and development to further enhance their manufacturing processes and capabilities. They are constantly exploring new technologies and methodologies to improve efficiency, reduce costs, and elevate the quality of their plastic parts.The announcement of mass producing plastic parts is a testament to [Company]'s vision and dedication to pushing the boundaries of what is possible in the manufacturing industry. Their innovative approach and unwavering commitment to quality and sustainability will undoubtedly have a significant impact on the industry and pave the way for a new era of manufacturing.In conclusion, [Company]'s ability to mass produce plastic parts at a higher volume and with a greater level of customization and sustainability sets them apart as a leader in the industry. Their groundbreaking approach will undoubtedly shape the future of manufacturing and open up new possibilities for businesses across various industries. With their unwavering commitment to excellence and innovation, [Company] is poised to continue setting new standards in the world of plastic manufacturing.

Top Plastic Manufacturers in the United States: Leading the Industry in Quality and Innovation

Plastic Manufacturers in the US Have Seen a Surge in DemandIn recent years, the demand for plastic products in the United States has been steadily increasing, leading to a surge in production for plastic manufacturers. As one of the leading plastic manufacturers in the country, {Company Name} has been at the forefront of this industry, catering to the growing needs of various sectors.{Company Name} has been a pivotal player in the realm of plastic manufacturing in the US. The company boasts a state-of-the-art production facility, equipped with the latest technology and machinery to ensure the highest quality of plastic products. With a dedicated team of experts and professionals, {Company Name} has been able to meet and exceed the expectations of their clients, solidifying their position as a trusted name in the industry.The recent surge in demand for plastic products in the US can be attributed to a variety of factors. With the growing popularity of e-commerce, the need for plastic packaging has risen significantly. Additionally, the construction and automotive industries have also contributed to the increased demand for plastic components and materials. As a result, plastic manufacturers like {Company Name} have seen a notable uptick in their production and sales.In response to the heightened demand, {Company Name} has ramped up its production efforts, streamlining its operations to meet the needs of its clients. This has involved implementing innovative manufacturing processes and adopting sustainable practices to ensure that the environment is not compromised in the process. Additionally, the company has put a strong emphasis on research and development, striving to create cutting-edge plastic products that are both durable and eco-friendly.The success of {Company Name} and other plastic manufacturers in the US can also be attributed to their ability to adapt to the ever-changing market dynamics. By staying abreast of the latest trends and technologies, these manufacturers have been able to stay ahead of the curve, catering to the evolving needs of their clients across various sectors.Furthermore, the COVID-19 pandemic has also had a significant impact on the plastic manufacturing industry. With the heightened focus on health and safety, there has been an increased demand for plastic products such as personal protective equipment, medical supplies, and packaging materials. {Company Name} has risen to the occasion, swiftly responding to these shifting market demands and ensuring that they are able to supply essential plastic products to those in need.In light of the current circumstances, {Company Name} has also made a concerted effort to give back to the community. By donating essential plastic products to healthcare facilities and frontline workers, the company has demonstrated its commitment to supporting the greater good during these challenging times.Looking ahead, the future of plastic manufacturing in the US appears to be promising. As the demand for plastic products continues to grow, manufacturers like {Company Name} are poised to play a crucial role in catering to the needs of various industries. By continuously innovating and adapting to the changing landscape, these manufacturers are well-positioned to thrive in an increasingly competitive market.In conclusion, the surge in demand for plastic products in the US has presented a significant opportunity for plastic manufacturers to showcase their capabilities and contribute to the growth of the industry. With their unwavering commitment to excellence and innovation, companies like {Company Name} are well-equipped to meet the evolving needs of their clients and deliver high-quality plastic products that satisfy a myriad of requirements.

Enchanting King Size Mattress Cover for Ultimate Bedroom Comfort

Mattress Pad, Waterproof King Size Mattress Cover, Memory Foam King Size Mattress Topper.Are you in need of a good night's sleep? Look no further than a king size mattress with the right accessories to ensure the ultimate comfort. One of the best investments you can make for your bed is a king size egg crate mattress pad. With 30 holes designed to cradle and support your body, this pad is perfect for those who suffer from pain or discomfort while sleeping.But protection is also essential in ensuring the longevity of your mattress, and that's where a waterproof king size mattress cover comes in. Not only does it shield against spills and stains, but it also protects from dust mites, bed bugs, and allergens that can cause health issues. Worry less about spills and stains with a waterproof cover that can be easily removed and washed.For those who prefer a little extra comfort, memory foam king size mattress toppers are an excellent option. With its ability to conform and support your body, a memory foam topper can greatly enhance the quality of your sleep. You'll wake up feeling refreshed and rejuvenated, ready to take on the day ahead.Overall, investing in the right accessories such as a king size egg crate mattress pad, waterproof mattress cover, and memory foam topper can make a significant difference in how you sleep. Not only will it provide added comfort, but it also ensures the protection of your mattress, creating a healthier sleeping environment. Take the first step towards your ultimate sleeping experience, starting with the right accessories for your king size mattress.