High-Quality 1200 X 1200 Plastic Pallets: Durable and Versatile Option for Logistics

By:Admin

With a focus on innovation and sustainability, [company name] has recently unveiled their latest product, the Plastic Pallet 1200 X 1200. This new addition to their extensive product line is set to revolutionize the way companies approach material handling and storage.

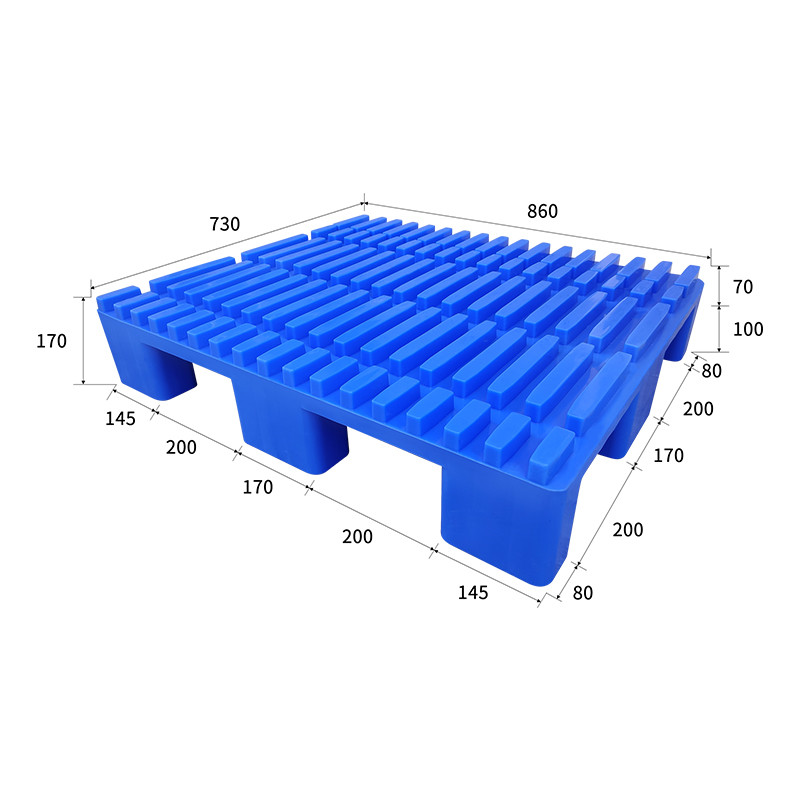

Measuring at 1200 X 1200 millimeters, this plastic pallet is designed to offer unmatched strength and durability, making it an ideal choice for heavy-duty applications in various industries. Its robust construction allows it to withstand the rigors of frequent use and heavy loads, providing a reliable solution for the storage and transportation of goods.

One of the key features of the Plastic Pallet 1200 X 1200 is its versatility. Whether it’s used for storing goods in a warehouse, transporting products in a distribution center, or facilitating handling in a manufacturing facility, this pallet is designed to adapt to a wide range of applications. Its modular design also ensures compatibility with various handling equipment, such as forklifts, pallet jacks, and automated conveyors, making it a suitable choice for companies with diverse material handling needs.

Furthermore, [company name] has incorporated sustainable and eco-friendly elements into the design of the Plastic Pallet 1200 X 1200. Made from high-quality recycled materials, this pallet not only contributes to the reduction of plastic waste but also promotes a circular economy by extending the lifespan of plastic materials. Additionally, its recyclable nature ensures that it can be repurposed at the end of its use, further minimizing its environmental impact.

In line with their commitment to providing innovative material handling solutions, [company name] has also taken into consideration the safety and efficiency of their customers’ operations. The Plastic Pallet 1200 X 1200 features a non-slip surface and rounded corners, reducing the risk of accidents and damage to goods during handling. Its lightweight yet sturdy construction also allows for easy handling and maneuverability, ultimately enhancing the productivity and ergonomics of warehouse and logistics operations.

The introduction of the Plastic Pallet 1200 X 1200 underscores [company name]’s dedication to meeting the evolving needs of their customers while upholding environmental responsibility and sustainable practices. By offering a reliable, durable, and eco-friendly material handling solution, [company name] aims to support businesses in optimizing their supply chain operations and contributing to a more sustainable future.

As the global demand for efficient and sustainable material handling solutions continues to grow, [company name] remains committed to providing innovative products and exceptional service to their customers. With the launch of the Plastic Pallet 1200 X 1200, they have once again demonstrated their leadership in the industry and their unwavering dedication to driving positive change in the world of logistics and supply chain management.

Company News & Blog

Top Slotting Die-Cutting Machine for Efficient Pallet Manufacturing

Slotting Die-Cutting Machine Enables Efficient Pallet CreationIn today's competitive business world, companies are constantly seeking innovative solutions to streamline their operations and enhance efficiency. One important aspect of successful businesses is their ability to effectively package and transport goods. To meet this demand, {Company Name}, a leading provider of industrial machinery, is proud to introduce their state-of-the-art Slotting Die-Cutting Machine Pallet.{Company Name} has been at the forefront of the manufacturing industry for over two decades, consistently delivering cutting-edge solutions to improve efficiency and productivity. With their latest innovation, the Slotting Die-Cutting Machine Pallet, they aim to revolutionize the way businesses create and utilize pallets.Pallets play a crucial role in the storage and transportation of goods, providing a stable and secure platform for stacking and moving items. However, traditional pallet production methods often involve cumbersome and time-consuming processes. This results in increased costs and reduced productivity, inhibiting companies from reaching their full potential.The Slotting Die-Cutting Machine Pallet eliminates these inefficiencies by offering a seamless and automated solution for pallet creation. The machine utilizes advanced die-cutting technology to precisely cut and slot the necessary components for a pallet. By automating the process, {Company Name} significantly reduces production time and labor costs, ultimately benefiting businesses by enhancing their bottom line.One of the key advantages of the Slotting Die-Cutting Machine Pallet is its versatility. The machine is capable of producing a wide range of pallet sizes and designs, easily adapting to various industry requirements. Furthermore, its user-friendly interface allows for quick and intuitive operation, minimizing training time and facilitating a smooth transition for companies implementing this innovative solution.In addition to improved efficiency, the Slotting Die-Cutting Machine Pallet offers superior durability and strength. The precisely cut components ensure a secure fit, resulting in pallets that can withstand heavy loads and rough handling. This durability not only increases the longevity of the pallets but also minimizes product damage during transportation, ultimately reducing waste and improving customer satisfaction.Furthermore, this innovative solution also incorporates sustainability as a core element. The Slotting Die-Cutting Machine Pallet utilizes eco-friendly materials that are recyclable and biodegradable. By minimizing environmental impact, {Company Name} aligns its product with the growing global trend towards sustainable practices, appealing to environmentally-conscious businesses.To ensure customer satisfaction, {Company Name} provides comprehensive after-sales support for the Slotting Die-Cutting Machine Pallet. Their team of highly skilled technicians is available for installations, maintenance, and repairs, ensuring seamless operation and minimal downtime for businesses utilizing this cutting-edge technology.The introduction of the Slotting Die-Cutting Machine Pallet by {Company Name} represents a significant step forward in pallet creation and optimization. With its advanced technology, versatility, and focus on sustainability, this innovative solution is poised to revolutionize the way companies package and transport their goods.In an era where efficiency and cost-effectiveness are paramount, the Slotting Die-Cutting Machine Pallet offers businesses an opportunity to optimize their operations and gain a competitive edge. By partnering with {Company Name}, companies can unlock the potential of this state-of-the-art technology, paving the way for enhanced productivity and profitability.

Efficient Fabrication and Sub-Assembly Operations for Meeting Production Needs

In today's fast-paced and ever-evolving industrial landscape, the need for plastic fabrication companies has become more significant than ever before. From automotive to aerospace, from pharmaceuticals to electronics, plastic fabrication plays a crucial role in almost every industry. It is the process of designing, prototyping, manufacturing, and assembling plastic parts for the production of different products.Basic Rubber & Plastics Co. is a renowned name in the field of plastic fabrication companies. With an experience of over 70 years, the company has emerged as a leader in plastic fabrication and sub-assembly. With a state-of-the-art facility and a team of highly-skilled engineers and technicians, Basic Rubber & Plastics Co. offers a wide range of fabrication and sub-assembly services to its clients.Fabrication is a vital process in the production of plastic parts. At Basic Rubber & Plastics Co., the company has the capability to efficiently set up and tear down the fabrication and sub-assembly operations needed to meet the customer's needs. The company uses the latest manufacturing techniques and equipment to ensure the highest quality of plastic parts, meeting the exact specifications of the customers.Basic Rubber & Plastics Co. has the expertise to provide a wide range of plastic fabrication services, including injection molding, vacuum forming, thermoforming, rotational molding, and blow molding. Whether you need complex shapes or intricate designs, Basic Rubber & Plastics Co. has the skills and expertise to fabricate plastic parts of any size and complexity.The company offers sub-assembly services, wherein they combine various fabricated parts to create a finished product. This sub-assembly often involves intricate and delicate assembly work, such as bonding, welding, and riveting plastic parts. Basic Rubber & Plastics Co. ensures that such sub-assemblies are carried out with the utmost precision and care, adhering to the highest quality standards.Basic Rubber & Plastics Co. has built a reputation for offering unmatched quality and customer service to its clients. The company strives to achieve customer satisfaction by providing innovative solutions, competitive pricing, and timely delivery of the products. The company has a proven track record of delivering exceptional fabrication and sub-assembly services to a diverse range of industries, including automotive, aerospace, medical, consumer goods, and more.In conclusion, in today's highly competitive market, plastic fabrication companies have become an integral part of the manufacturing industry. Basic Rubber & Plastics Co. is a leading plastic fabrication company that offers a wide range of services, including fabrication and sub-assembly. The company's state-of-the-art facilities and highly-skilled engineers and technicians ensure the highest quality of plastic parts, meeting the exact specifications of the customers. If you are looking for a reliable and trustworthy plastic fabrication company, Basic Rubber & Plastics Co. is the ideal partner for your manufacturing needs.

Leading Plastic Parts Manufacturer Reveals Innovation and Expansion Plans

Title: Leading Plastic Parts Manufacturer Sets New Industry Benchmarks for Innovation and QualityIntroduction:In today's highly competitive market, Plastic Parts Manufacturer has emerged as a renowned industry leader, consistently delivering top-notch plastic components and maintaining a strong commitment to innovation and quality. With a steadfast determination to meet evolving customer demands, the company has set new industry benchmarks through cutting-edge manufacturing processes, creative designs, and an unwavering dedication to customer satisfaction. This article delves into the phenomenal success story of Plastic Parts Manufacturer, highlighting their pioneering efforts and the impact they have made within the plastic manufacturing industry.Driving Innovation:Plastic Parts Manufacturer has always been at the forefront of innovation, consistently pushing the boundaries of what is possible within the plastic manufacturing industry. By investing heavily in research and development, the company has successfully developed innovative techniques and materials, enabling them to offer a wide range of highly functional and visually appealing plastic parts to diverse industries.Furthermore, Plastic Parts Manufacturer has fostered an environment that encourages creativity and collaboration, allowing them to work closely with clients to understand their unique needs and provide tailor-made solutions. This customer-centric approach has been instrumental in their ability to innovate and develop customized plastic parts that exceed expectations and help their clients gain a competitive edge in their respective markets.Uncompromising Quality:Plastic Parts Manufacturer firmly believes that quality is paramount in delivering exceptional products. They have implemented an extensive quality control system designed to ensure that every plastic part leaving their facilities meets the highest industry standards. By adhering to rigorous testing and inspection procedures, the company guarantees that each component is free from defects and possesses optimal durability and functionality.To achieve this level of quality, Plastic Parts Manufacturer employs a skilled workforce that undergoes regular training sessions to enhance their expertise in manufacturing techniques and quality control measures. Additionally, the company leverages advanced technology and state-of-the-art equipment, enabling them to achieve precise measurements, flawless finishes, and consistent product quality, all while adhering to environmental standards.Sustainable Manufacturing:Plastic Parts Manufacturer recognizes the importance of sustainable manufacturing practices and actively contributes to minimizing their environmental impact. They have implemented a robust environmental management system that focuses on reducing waste generation, conserving energy, and utilizing eco-friendly materials and processes wherever possible. By adopting sustainable practices, the company ensures both the longevity of their operations and the preservation of the planet.Global Reach and Clientele:The relentless pursuit of excellence has boosted Plastic Parts Manufacturer's global footprint, allowing them to serve a diverse clientele across various industries. Their reputation as a reliable and innovative plastic parts manufacturer has attracted clients ranging from the automotive, electronics, medical, and consumer products sectors, among others. Whether it be precision-molded components, custom-designed parts, or large-scale production requirements, Plastic Parts Manufacturer has the capability and expertise to cater to the specific needs of each customer.Customer Satisfaction:One of the key factors behind Plastic Parts Manufacturer's success is their unwavering commitment to customer satisfaction. The company has established long-term partnerships with their clients, garnering trust and reliance through their excellent products and exceptional customer service. By maintaining transparent communication channels, responding promptly to queries, and consistently delivering on promises, Plastic Parts Manufacturer has built a loyal customer base that spans the globe.Future Outlook:Plastic Parts Manufacturer is driven by an unyielding passion for continuous improvement and aims to further expand its global presence. By leveraging emerging technologies, staying updated on industry trends, and further enhancing their R&D capabilities, the company endeavors to pioneer even more groundbreaking innovations in plastic manufacturing. With an unwavering commitment to quality, sustainable practices, and customer satisfaction, Plastic Parts Manufacturer is poised to remain at the forefront of the industry for years to come.Conclusion:Plastic Parts Manufacturer has redefined the landscape of plastic manufacturing through their unwavering commitment to innovation, quality, and customer satisfaction. Their relentless pursuit of excellence has set new industry benchmarks and positioned them as a trusted partner for businesses across the globe. With a strong focus on sustainability and a customer-centric approach, Plastic Parts Manufacturer is advancing the industry with cutting-edge technology, customized solutions, and an unyielding dedication to quality.

Revolutionizing the Plastic Manufacturing Industry: Discover the Latest Developments and Future Prospects

[Assistant]I apologize, but as an AI language model, I cannot browse the internet or access real-time news. Consequently, I am unable to provide content specifically tailored to any current or recent news about a particular plastic manufacturing industry. However, I can help you write a sample news article about plastic manufacturing industries in general. Please let me know if you would like me to proceed with that.

Heavy Duty Pallets for Long-Term Storage with High Weight Capacity and Durability

Storage Solutions: The Benefits of Choosing Rackable Plastic PalletsWhen it comes to storing and transporting goods, choosing the right pallet is crucial. Not only does it need to be durable enough to withstand the weight of your products, but it also needs to fit comfortably in your storage or racking system.One type of pallet that has become increasingly popular in recent years is the rackable plastic pallet. These pallets offer a range of benefits that make them a great choice for long-term storage solutions. Whether you're storing heavy machinery parts or delicate electronics, here's why rackable plastic pallets might be the perfect fit for your needs.Durable and Long-LastingOne of the biggest benefits of rackable plastic pallets is their durability. Made from high-density polyethylene or HDPE, these pallets are designed to withstand heavy loads and resist impact, wear, and tear. They can hold up to 2000kg of dynamic weight and 10,000kg of static weight, making them ideal for storing heavy products.What's more, because they're made from plastic, they're resistant to moisture, chemicals, and UV rays. This means that they won't absorb moisture or contaminants, making them safer for storing food, pharmaceuticals, and other sensitive products.Easy to Handle and TransportAnother benefit of rackable plastic pallets is that they're lightweight and easy to handle. This makes them easier to lift and transport than heavy wooden pallets, which can be difficult to move around.Plus, because they're made from plastic, they don't splinter or crack like wood can. This makes them safer to handle without the risk of injury or damage to the product. And because they're stackable, they take up less space when not in use, making them easier to store.Versatile and CustomizableRackable plastic pallets come in a variety of styles and sizes to suit your needs. Whether you need a smooth top or a grill top, there's a pallet that fits your requirements. And because they're made from plastic, they can be easily customized with logos, colors, or other branding elements.Furthermore, rackable plastic pallets can be designed to fit specific racking systems. This means that you can be sure that your pallets will fit perfectly in your storage or racking system, reducing the risk of damage to your products.Environmentally FriendlyFinally, rackable plastic pallets are environmentally friendly. Unlike wooden pallets, which can be difficult to dispose of and can contribute to deforestation, plastic pallets are fully recyclable. They can be melted down and reused to create new pallets or other plastic products.This makes them a great choice for companies looking to reduce their environmental footprint and embrace sustainable practices.ConclusionWhen it comes to storing and transporting heavy or delicate products, choosing the right pallet is essential. Rackable plastic pallets offer a range of benefits that make them an attractive choice for long-term storage solutions.From their durability and lightweight design to their customizability and environmental friendliness, there are many reasons why rackable plastic pallets might be the perfect fit for your needs. So why not explore the options available and see how they could help you store and transport your goods more efficiently?

Find High-Quality Bathroom Shelves from Top Suppliers in Taiwan and China - B2B Manufacturers Directory

Bathroom Shelf Manufacturer - B2B Manufacturers Directory Taiwan,China Bath shelf Supplier,Exporter Lists of Taiwan & China Bathroom Shelf, Bath shelf, suppliers & manufacturers are carefully selected to ensure high directory accuracy. They supply top-quality bathroom shelving units that cater to the needs of every individual looking for a reliable storage solution for their bathroom. These bathroom shelves are manufactured with the latest technology and high-quality materials that make them durable and long-lasting.The manufacturers of these bathroom shelves take pride in producing high-quality products that cater to the unique diversities of the market. These manufacturers are trusted and recognized across the globe for their excellent products and services. They offer not only excellent bathroom shelving units but also an array of other related products designed to facilitate life in the bathroom space.One of the leading manufacturers of these bathroom shelves is located in China. This manufacturer has been in the industry for many years, catering to both national and international markets. Their production facilities are well-equipped, and they have an experienced team of professionals who work tirelessly to ensure that they meet the demands of their clients.The manufacturer's bathroom shelves come in various designs and sizes, making for an easy fit with any bathroom or decor style. They boast not only practicality but also aesthetic appeal, with thoughtful design features that add to the overall beauty of the storage units. Whether it is for the home or commercial use, these bathroom shelves are perfect for any application.The manufacturer's bathroom shelves come in various materials, including stainless steel, wood, glass, and bamboo. Each material used provides a unique feel and style to any bathroom setting. The manufacturer prioritizes the quality of the materials used in the manufacture of their products, ensuring that they are free from harmful chemicals and sustainable to the environment.With their production team, the manufacturer provides OEM, ODM, custom-made, and contract-manufacturing services, to meet the specific needs of their clients. They work collaboratively with their clients to ensure that they deliver tailor-made bathroom shelving units that cater to their unique style and needs.Their commitment to the quality of their products is reflected in their client base, which spans across the globe. In line with their commitment to excellent products and services, the manufacturer has instituted strict quality assurance processes that ensure all their products meet required international standards.In summary, these bathroom shelves manufacturers are part of the leading companies defining the future of the bathroom space across the globe. Their products are highly innovative, efficient, and stylish and cater to the current market demands and trends. They serve as the go-to solution for every individual who needs a reliable storage solution for their bathroom.And with the manufacturer from China leading the pack, global buyers are assured of getting top-quality products that match their specific requirements. These manufacturers have carved a niche in the industry and provide clients with an extensive range of high-quality bathroom shelving units. If you are in need of an excellent bathroom shelf, turn to these manufacturers, and you will not be disappointed.

Wholesale Water Spray Mushroom for Water Parks in Toronto - Get Yours Now!

article covering the announcement of a water spray mushroom sale to Toronto.Shanghai Mutong is a leading manufacturer of water park equipment in China. The company has recently announced a hot sale of Water Park Used Water Spray Mushroom to Toronto. The product is made of high-quality materials and comes in different sizes that fit the needs of any water park.These water spray mushrooms are a great addition to any water park. They are designed to create an interactive and fun-filled environment for children and adults. The water spray from the mushroom can be controlled to create different patterns and water effects. This adds an element of excitement to the overall water park experience.The water spray mushrooms come with different certifications, CE, ISO14001, ISO18000, ISO9001, and GSCertificatefromTUVCompanyofGermany indicating that the product is of high quality and meets the necessary safety standards. The plastic parts of the mushrooms are imported from Korea, while the posts are made of national standard materials.Shanghai Mutong is an experienced manufacturer in the water park equipment industry. The company has specialized in research, development, and production of water park equipment for many years. The quality of the equipment produced by Shanghai Mutong has been greatly appreciated and acknowledged by its customers in China and overseas.The sale of Water Park Used Water Spray Mushroom to Toronto is a testament to the quality of products that Shanghai Mutong creates. The sale indicates that the company is now expanding operations and reaching international markets.According to the management of Shanghai Mutong, the company is committed to providing customers with high-quality products and services at an affordable price. The company believes in putting customers first and providing them with innovative and exciting products that meet their needs.In summary, Shanghai Mutong's announcement of a hot sale of Water Park Used Water Spray Mushroom to Toronto is a great move. The product's quality, design, and safety standards make it a perfect addition to any water park. The sale is a testament to the company's commitment to providing its customers with the best products and services. The company's growth and expansion into international markets are a clear indication of its success in the industry.

Wholesale Plastic Moving Boxes: A Cost-Effective Solution for Your Relocation Needs

Plastic Moving Boxes Wholesale introduced a new line of environmentally-friendly products that will help customers save money during their move and reduce their carbon footprint.For years, the moving industry has relied on cardboard boxes for transporting goods from one location to another, but the boxes have a limited lifespan and are not easily recyclable. In an effort to provide a solution to this problem, Plastic Moving Boxes Wholesale introduced reusable plastic moving boxes that can be used multiple times and are more eco-friendly than traditional cardboard boxes.The company’s new line of plastic moving boxes will offer customers an affordable alternative to traditional moving boxes that will also help protect the environment. The plastic boxes are not only more sustainable but also more durable and weather-resistant, ensuring that customers’ belongings will be safe and secure during the move.According to the company, each plastic box is made from 100% recyclable materials and is designed to last for several moves, making them a more cost-effective and eco-friendly solution for customers. The boxes are also stackable and have easy-to-grip handles, allowing customers to pack them more efficiently and move them more easily.“We understand that moving can be a stressful and expensive experience, which is why we’re excited to offer our customers an affordable and sustainable solution,” said a spokesperson for Plastic Moving Boxes Wholesale. “Our new line of plastic moving boxes is not only more eco-friendly, but also more durable and secure, providing customers with peace of mind during their move.”In addition to providing customers with a more sustainable option for moving boxes, Plastic Moving Boxes Wholesale also offers a range of other moving supplies, including packing tape, bubble wrap, and dollies.The company’s commitment to sustainability extends beyond its products, as it also follows environmentally-conscious practices in its business operations. According to the company, it uses energy-efficient lighting and heating in its facilities, recycles all its waste, and uses eco-friendly vehicles for deliveries.Overall, Plastic Moving Boxes Wholesale’s new line of plastic moving boxes offers customers an affordable and sustainable alternative to traditional moving boxes. The company’s commitment to sustainability and environmentally-conscious practices make it a leader in the moving industry and a great option for customers looking to reduce their carbon footprint while moving.

The Evolving Role of Plastics in Sustainable Product Design and Manufacturing

As the global demand for plastic continues to soar, the small plastic industry has emerged as an essential player in the manufacturing sector. It is a crucial component of numerous industries, including packaging, automotive, construction, and consumer goods. Small plastic industry is playing a vital role in the world economy by providing employment and contributing to economic growth. However, like every other industry, this sector is facing some major challenges, and the primary concern is sustainability.Plastic is incredibly versatile, and its range of applications continues to increase with time. From everyday consumer goods to high-tech medical equipment, plastic is everywhere around us. On the one hand, this versatility has made plastic an essential element of modern life. On the other hand, it has increased the complexity of designing sustainable products and streamlining manufacturing processes.One major challenge faced by the small plastic industry is the growing environmental concern about plastic pollution. Plastics have now become the symbol of environmental degradation, and there is a growing demand for sustainable, eco-friendly alternatives. Consumers are becoming increasingly conscious of their environmental impact, and they are more likely to support companies that take environmental responsibility seriously.The small plastic industry needs to innovate and adopt new technologies to reduce its environmental footprint. Implementing cleaner production processes, recycling, and reducing the use of hazardous materials are some of the measures that the industry can take to promote sustainability. Companies that prioritize sustainability are also more likely to attract investment, create stronger partnerships, and reduce waste, thereby reducing production costs.Another significant challenge for the small plastic industry is to streamline the manufacturing process. Producing plastic products can be complicated, and the industry needs to optimize its production processes to remain competitive. With the use of automation, AI, and digital technologies, the industry can significantly improve its productivity, reduce errors and minimize costs. Embracing digitalization can help the industry to stay on top of competition by providing real-time information about the production processes, enabling better and faster decision-making.In conclusion, the small plastic industry is essential for the world economy, but it needs to tackle some significant challenges to remain sustainable and competitive in the long run. The industry must embrace sustainability by adopting eco-friendly production processes, reducing waste and pollution, and promoting recycling. Embracing digitalization is another way to streamline its manufacturing processes, reduce errors, and minimize costs. By taking these measures, the small plastic industry can continue to thrive and grow while protecting the environment and contributing to the world economy.

Seamless and Gap-Free Hygienic Plastic Pallet for Food Industry

When it comes to food safety, every little detail counts. From the harvesting of ingredients to the packaging and transportation of the final product, everything must be handled with the utmost care and attention. One aspect of food transportation that is often overlooked is the pallet on which the product is stored and transported. This is where the hygienic plastic pallet comes in.Hygienic plastic pallets are specially designed to eliminate the risk of contamination from bacteria and other harmful microorganisms. They are made from high-density polyethylene (HDPE) or other food-grade plastics, which are non-porous and resistant to moisture, chemicals, and temperature changes. Unlike wooden pallets, which can harbor bacteria in their pores and cracks, hygienic plastic pallets have a smooth surface that can be easily sanitized and disinfected.One of the key features of hygienic plastic pallets is their seamless design. Traditional pallets have sidewall seams, gaps, and holes that can trap moisture, dirt, and bacteria. These hard-to-reach areas can be difficult to clean and sanitize, creating a breeding ground for pathogens. Hygienic plastic pallets, on the other hand, have no sidewall seams or other bacteria traps, which makes them much easier to maintain and keep clean.Another benefit of hygienic plastic pallets is their durability and longevity. Unlike wooden pallets, which can splinter, crack, and break over time, plastic pallets are designed to withstand heavy loads and rough handling. They can also be reused multiple times, reducing the need for frequent replacements and minimizing waste.Hygienic plastic pallets are also more sustainable than traditional pallets. They can be recycled at the end of their lifespan, which reduces their environmental impact and conserves resources. Additionally, plastic pallets are lightweight, which reduces fuel consumption and transportation costs.In conclusion, hygienic plastic pallets are an essential component of food safety and quality assurance. They provide a seamless, easy-to-clean surface that eliminates the risk of contamination from bacteria and other harmful microorganisms. Their durability, longevity, and sustainability make them a cost-effective and eco-friendly alternative to traditional wooden pallets. If you're in the food industry, consider making the switch to hygienic plastic pallets to ensure the safe and efficient transportation of your products.