High-Quality Plastic Moulded Parts for Various Industries

By:Admin

Founded in 1995, Plastic Moulded Parts has a long history of providing top-notch plastic components to their clients. The company's state-of-the-art manufacturing facility is equipped with the latest technology and machinery, allowing them to produce a wide variety of plastic parts with precision and efficiency. Their team of skilled engineers and technicians is dedicated to delivering the highest quality products, and their commitment to continuous improvement ensures that they stay at the forefront of the industry.

One of Plastic Moulded Parts' key strengths is their ability to work closely with their clients to develop custom solutions that meet their specific needs. Whether it's a small batch of parts for a prototype or a large production run, Plastic Moulded Parts has the expertise and resources to deliver exceptional results. Their in-house design and engineering capabilities enable them to turn their clients' ideas into reality, and their streamlined production processes ensure that projects are completed on time and within budget.

In addition to their custom manufacturing services, Plastic Moulded Parts also offers a wide range of standard plastic components that are available for immediate delivery. Their extensive catalogue includes everything from simple brackets and fasteners to complex assemblies, providing their clients with a convenient one-stop shop for all of their plastic component needs. With a focus on quality and reliability, Plastic Moulded Parts has earned a reputation for delivering products that meet the highest standards of performance and durability.

Plastic Moulded Parts serves a diverse clientele that spans a variety of industries, including automotive, aerospace, medical, and consumer electronics. Their ability to provide innovative solutions for complex applications has made them a preferred supplier for many leading companies, and their commitment to excellence has earned them the trust and loyalty of their clients. Whether it's a multinational corporation or a small startup, Plastic Moulded Parts is dedicated to providing every client with the same level of attention and care.

Plastic Moulded Parts' dedication to sustainability is evident in their manufacturing practices, as they are committed to reducing their environmental impact. By utilizing cutting-edge materials and processes, they are able to minimize waste and energy consumption while maximizing efficiency. They also strive to develop new eco-friendly materials and technologies that will further reduce their carbon footprint, ensuring that they remain at the forefront of sustainable manufacturing practices.

Looking to the future, Plastic Moulded Parts is poised to continue their tradition of excellence and innovation. By investing in new technology, expanding their capabilities, and fostering strong partnerships with their clients, they are well-positioned to meet the evolving needs of the industry and maintain their leadership in the market. With a proven track record of success and a dedication to continuous improvement, Plastic Moulded Parts is a company that is truly shaping the future of plastic component manufacturing.

In conclusion, Plastic Moulded Parts stands as a shining example of a company that is dedicated to providing the highest quality products and services to their clients. With a focus on innovation, sustainability, and customer satisfaction, they have earned a reputation as a trusted partner for businesses across a wide range of industries. As they continue to push the boundaries of what is possible in plastic component manufacturing, Plastic Moulded Parts is poised to remain a leader in the industry for years to come.

Company News & Blog

Plastic Pallets for Printing and Converting Industry Presses

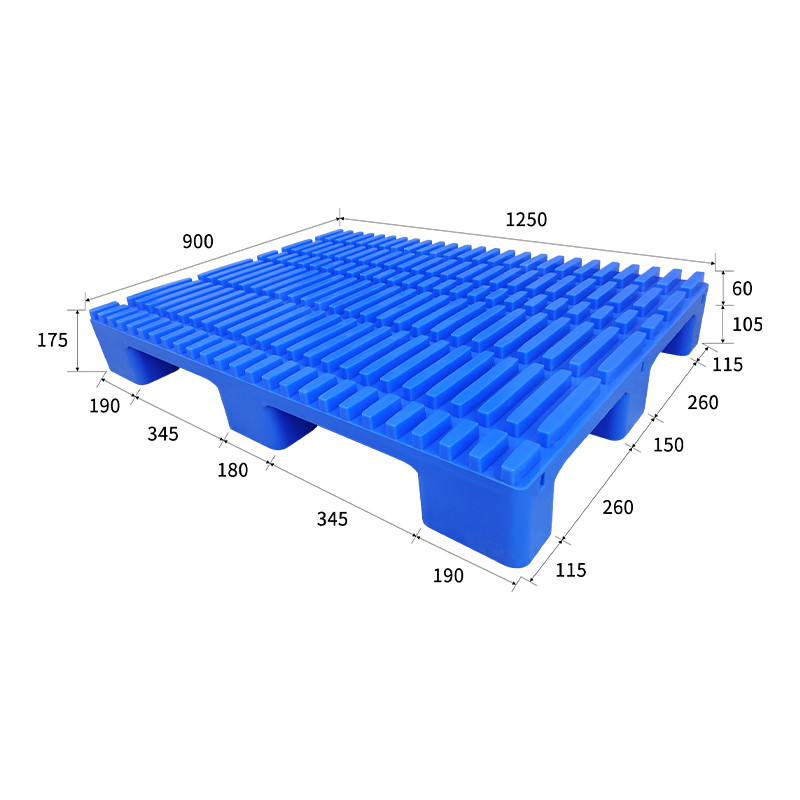

The printing and converting industry requires pallets that are specially designed to meet their unique needs. These industries demand pallets that are durable, lightweight, and easy to maneuver. Plastic press pallets, such as the Pallet XL 105, have become increasingly popular for companies in the printing industry.One of the primary benefits of plastic press pallets is their compatibility with many die cutting and printing presses. This makes them an ideal choice for companies that require frequent movement of materials during the printing process. Not only are these pallets sturdy and strong, but they also save time and labor by reducing the need for manual handling and loading.The Pallet XL 105 is a plastic pallet that has been designed specifically for the printing industry. Made from high-density polyethylene, this pallet is both lightweight and strong, with a maximum load capacity of 2,650 pounds. The pallet's size is also optimized for use with printing presses, measuring 44 inches by 52 inches.In addition to their durability and compatibility with printing equipment, plastic press pallets offer numerous other advantages over traditional wooden pallets. For one, they are resistant to moisture, mold, and pests, making them more hygienic and easier to maintain. Plastic pallets also have a longer lifespan than wooden pallets, which can break or splinter over time.Another advantage of plastic press pallets is their ease of cleaning and sanitizing. Many printing and converting facilities require strict hygiene standards, and plastic pallets can be quickly and easily sanitized with a pressure washer or steam cleaner. They are also less likely to harbor bacteria or other contaminants than wooden pallets.Overall, plastic press pallets like the Pallet XL 105 are an excellent choice for companies in the printing and converting industries. They offer durability, compatibility, and ease of use, while also being more hygienic and environmentally friendly than traditional wooden pallets. Whether you're moving materials around the shop floor or transporting products across the country, plastic press pallets are a reliable and cost-effective solution.

High-Quality Custom Plastic Injection Molding Made in America - Contact Us Today!

Custom Plastic Injection Molding: Innovative Solutions for Your Manufacturing NeedsPlastic injection molding is a manufacturing process that has revolutionized the way products are made. With its unparalleled precision, speed, and reliability, plastic injection molding offers businesses and individuals a cost-effective way to create complex, high-quality parts and products in large quantities.One of the most experienced, reliable, and innovative players in the global plastic injection molding industry is the Rodon Group, a Pennsylvania-based company that has been offering customized plastic injection molding services for over 60 years. As an ISO 9001:2015 certified company, the Rodon Group is committed to producing molded parts of the highest quality that meet or exceed the most demanding industry standards. By combining cutting-edge technology, state-of-the-art equipment, and a highly skilled team of engineers and technicians, the Rodon Group has established itself as a leader in the plastic injection molding industry.Customized Plastic Injection Molding ServicesThe Rodon Group is fully equipped to handle your custom plastic injection molding needs, no matter how complex or challenging they may be. With a wide range of injection molding machines ranging from 25 to 400 tons of clamping pressure, the Rodon Group can produce parts weighing from less than a gram to over 500 grams.Whether you need a small, intricate component or a larger, more complex part, the Rodon Group has the expertise to deliver customized plastic injection molding solutions to meet your specific requirements. With a focus on cost-effectiveness and quality assurance, the Rodon Group can help you produce high-quality plastic parts at a competitive price.The Benefits of Customized Plastic Injection MoldingCustomized plastic injection molding offers a wide range of benefits to businesses and individuals looking to create high-quality parts and products. Here are just a few key advantages of this process:1. Cost-effectiveness: Customized plastic injection molding is an affordable way to produce high-quality parts and products in large quantities. By utilizing high-volume production processes, the Rodon Group can help you enjoy significant cost savings.2. Quality assurance: With its precision and consistency, customized plastic injection molding is an ideal way to produce parts that meet the highest quality standards. Through its strict quality control processes, the Rodon Group ensures that every part it produces meets or exceeds its customers' expectations.3. Speed and efficiency: With its fast cycle times and high-volume production capabilities, customized plastic injection molding is an efficient way to produce parts in large quantities. By leveraging its cutting-edge technology and state-of-the-art equipment, the Rodon Group can help you improve your speed-to-market and response times.4. Design flexibility: With customized plastic injection molding, you can create parts that are highly detailed, complex, and aesthetically pleasing. Through its in-house design and engineering services, the Rodon Group can help you create parts that meet your unique specifications and requirements.Why Choose the Rodon Group?There are many reasons why the Rodon Group is the top choice for businesses and individuals looking for customized plastic injection molding services. Some of the key advantages of working with the Rodon Group include:1. Expertise: With over 60 years of experience in the plastic injection molding industry, the Rodon Group has the knowledge, skills, and expertise needed to deliver innovative and customized solutions to meet your manufacturing needs.2. Reliability: With a commitment to quality and service, the Rodon Group has established itself as a trusted and reliable partner for businesses and individuals looking for customized plastic injection molding services.3. Technology: The Rodon Group leverages the latest technology and equipment to produce parts that are precise, consistent, and of the highest quality.4. Customer service: The Rodon Group is dedicated to providing exceptional customer service and support, working closely with its customers to ensure their needs are met.Contact the Rodon Group TodayIf you're looking for customized plastic injection molding solutions that deliver precision, speed, and quality, look no further than the Rodon Group. With over 60 years of experience, cutting-edge technology, and a team of highly skilled engineers and technicians, the Rodon Group has the expertise and resources needed to help you produce high-quality plastic parts and products that meet your unique requirements. Contact the Rodon Group today to learn more about its customized plastic injection molding services.

High-Capacity, Versatile Plastic Pallets: Ideal for Export and Pharmaceutical Industries

Title: Innovative Plastic Pallets: Revolutionizing Export Packaging SolutionsIntroduction:Plastic pallets have gained significant popularity in recent years, revolutionizing the export packaging industry due to their durability, cost-effectiveness, and eco-friendliness. This article will explore the load capacity, size, and unique applications of plastic pallets, especially focusing on euro plastic pallets and their contribution to transforming the export packaging sector.Company Introduction: [Insert Company Name][Company Name] is a leading manufacturer and supplier of high-quality plastic pallets. With a strong focus on innovation, we aim to provide sustainable, safe, and efficient packaging solutions for various industries. Our extensive range of plastic pallets ensures superior loading capacity, durability, and traceability, making them the ideal choice for export shipments.Load Capacity of Plastic Pallets:One of the key advantages of plastic pallets is their remarkable load capacity. Unlike their traditional wooden counterparts, plastic pallets are engineered to withstand heavy loads without warping, cracking, or breaking. With load capacities ranging from 1000kg to 2000kg, these versatile pallets are suitable for a wide range of applications, including the transportation of heavy machinery, automotive parts, pharmaceuticals, and more.Specialized Sizes for Different Industries:Plastic pallets come in various sizes to accommodate different industry requirements. Standard sizes include 1200x1000mm and 800x1200mm, which are widely used for general export purposes. Additionally, custom sizes can be manufactured to cater to specific industry needs, ensuring maximum efficiency and utilization of storage space during transportation.Export-Specific Euro Plastic Pallets:Euro plastic pallets have emerged as a popular choice for export shipments due to their standardized dimensions and compatibility with various transportation modes. These pallets adhere to the European Pallet Association (EPAL) standards, guaranteeing seamless integration within the global supply chain network. Euro plastic pallets typically measure 1200x800mm, making them an ideal choice for exporting goods to European countries.Advantages of Euro Plastic Pallets:Euro plastic pallets offer several unique advantages, making them the preferred choice for export-oriented businesses:1. Traceability: Euro plastic pallets are marked with identifiable logos and codes, ensuring easy tracking and traceability throughout the shipping process. This enables efficient inventory management and reduces the risk of lost or misplaced pallets.2. Hygiene and Compliance: Euro plastic pallets are easy to clean, reducing the risk of contamination during the transportation of pharmaceuticals and food products. They also comply with international regulations on sanitation, making them suitable for industries with strict hygiene requirements.3. Improved Ergonomics: These pallets are designed with ergonomic features such as anti-slip surfaces and reinforced corners, ensuring safe handling during loading and unloading processes. This reduces the risk of workplace injuries and enhances overall operational efficiency.Expanding Opportunities for Sustainable Export Packaging:Plastic pallets not only offer enhanced durability and load capacity but also contribute to environmental sustainability. Unlike wooden pallets, plastic pallets are reusable, recyclable, and do not require fumigation for international shipments. By opting for plastic pallets, businesses can reduce their carbon footprint and contribute to a greener future.Conclusion:Plastic pallets, with their exceptional load capacity, specialized sizes, and unique applications, have transformed the export packaging industry. Euro plastic pallets, in particular, have gained significant traction due to their adherence to global standards. As [Company Name] continues to innovate, our robust range of plastic pallets ensures safe and eco-friendly transportation of goods across various industries, revolutionizing the export packaging sector.

New study reveals alarming levels of microplastic contamination in plastic parts

Plastic Parts Expands its Services in the Manufacturing IndustryPlastic Parts, a leading manufacturer of injection-molded plastic parts, is expanding its services to cater to the growing demands of the manufacturing industry. The company has been in the business for over 30 years and has developed a reputation for providing high-quality plastic parts to various industries. With the expansion, Plastic Parts aims to offer its clients a more comprehensive range of manufacturing solutions.The expansion includes the acquisition of state-of-the-art machinery and equipment, as well as the integration of advanced manufacturing techniques into its processes. The company has invested heavily in research and development to come up with innovative solutions that can meet the evolving needs of its clients. The expansion also involves the hiring of additional personnel, including engineers, technicians, and operators, to support the new services."We are thrilled to announce the expansion of our services, which is a testament to our commitment to providing our clients with the best manufacturing solutions possible," said the company's spokesperson. "With the newly acquired machinery and the integration of advanced manufacturing technologies, we are confident that we can provide our clients with faster turnaround times, improved product quality, and competitive pricing."Plastic Parts provides a wide range of manufacturing services, including custom plastic injection molding, overmolding, insert molding, and rapid prototyping. With the expansion, the company is now offering additional services that include CNC machining, 3D printing, and assembly and packaging services. The new services will enable Plastic Parts to offer a one-stop-shop solution for its clients, thus saving them time and costs associated with working with multiple manufacturers.CNC machining is a process that involves the use of computer-controlled machines to produce precise parts from a variety of materials, including plastics, metals, and composites. Plastic Parts' CNC machining services offer high precision and tight tolerances, making it suitable for producing complex parts with intricate geometries. The company's CNC machines are equipped with the latest software technology that allows for efficient and accurate production.3D printing, on the other hand, is a process that involves creating a physical object from a digital design file. The technology has been rapidly evolving over the years, and Plastic Parts has invested in the latest 3D printing technology to offer its clients the most advanced solutions available. The company's 3D printing services cater to clients who require small volumes of parts or who need to produce prototypes quickly.Assembly and packaging services are also a new addition to Plastic Parts' portfolio. The company's assembly services involve the integration of various components to create a finished product, while its packaging services involve the design and production of custom packaging that protects the product during shipping and storage. The services are designed to provide a complete end-to-end solution for clients who want to focus on their core business and leave the manufacturing to experts.Plastic Parts' expansion is timely, given the growing demand for high-quality manufacturing solutions. The company's new services will enable it to expand its reach to new markets and offer its existing clients a more comprehensive range of solutions. With its team of experienced engineers and technicians and its state-of-the-art facilities, Plastic Parts is well-positioned to meet the needs of its clients and stay ahead of the competition.In conclusion, Plastic Parts' expansion is a significant milestone in the company's journey to become a leader in the manufacturing industry. With the new services, the company is poised to provide its clients with faster turnaround times, improved quality, and competitive pricing. The expansion also demonstrates Plastic Parts' commitment to innovation and excellence and its focus on staying ahead of the curve. As the manufacturing industry continues to evolve, Plastic Parts is well-prepared to meet the challenges and seize the opportunities that come its way.

Discover the Latest Developments in High-Quality Pallet Racks from China

Title: China's Dynamic Pallet Rack Industry Poised for Continued GrowthIntroduction:China has emerged as a global leader in various industries, with its vast manufacturing capabilities and thriving economy. Among the many sectors experiencing rapid growth, the pallet rack industry stands out as an essential component in meeting the warehousing and storage needs of businesses. Leading the charge in the market is China Pallet Rack, a renowned and innovative company dedicated to providing high-quality storage solutions. Incisive Company Overview:China Pallet Rack has garnered significant recognition over the years for its cutting-edge technology, superior products, and exceptional customer service. With a strong commitment to innovation and continuous improvement, the company has successfully established itself as a key player in the global pallet rack industry.With a diverse range of products, China Pallet Rack offers an extensive selection of pallet racking systems designed to maximize warehouse storage space and streamline inventory management. The company excels in manufacturing heavy-duty storage solutions that cater to various industries such as logistics, manufacturing, retail, and more. China Pallet Rack's core values prioritize safety, efficiency, and adaptability, ensuring their solutions are tailored to each client's specific needs. With an unwavering focus on quality control, the company employs stringent measures to ensure their products meet industry standards, making them a trusted choice for businesses worldwide.Unleashing New Technologies:As the pallet rack industry evolves, China Pallet Rack remains at the forefront by consistently investing in research and development. By embracing the latest technological advancements, the company continually introduces innovative storage solutions that address evolving industry demands.One notable breakthrough is the integration of intelligent automation systems into their pallet rack designs. By incorporating features such as automated retrieval systems, RFID tagging, and real-time inventory tracking, China Pallet Rack enhances efficiency, reduces human error, and improves overall warehouse productivity. These developments are instrumental in enabling businesses to stay competitive in an ever-evolving market.Global Expansion:The success of China Pallet Rack has not gone unnoticed, with the company rapidly expanding globally. They have established distribution networks in numerous countries, showcasing their commitment to serving a diverse range of clients worldwide. By partnering with local distributors, China Pallet Rack ensures seamless integration and prompt customer support, irrespective of geographical boundaries.Additionally, the company's dedication to sustainability is evident in its eco-friendly manufacturing processes. China Pallet Rack employs sustainable materials and implements energy-efficient practices in their production facilities, reducing their carbon footprint and contributing to a greener future.Industry Collaboration and Recognition:China Pallet Rack's dynamic growth can be attributed, in part, to its commitment to collaboration within the industry. By actively engaging in partnerships with warehousing and logistics organizations, the company gains valuable insights, allowing them to develop solutions that meet the evolving needs of their clients. Such collaboration not only enhances the quality of their products but also contributes to the overall growth of the pallet rack industry.Furthermore, China Pallet Rack's dedication to excellence has been widely recognized both within China and globally. The company has consistently won prestigious awards for their outstanding contributions and product innovation, solidifying their position as an industry leader.Conclusion:China Pallet Rack's relentless pursuit of excellence, commitment to innovation, and dedication to customer satisfaction have propelled them to the forefront of the pallet rack industry. With their advanced technologies, versatile product range, and global expansion strategies, the company is set to continue its remarkable growth trajectory. As China's manufacturing sector continues to thrive, the pallet rack industry, led by China Pallet Rack, will undoubtedly play a significant role in shaping the future of warehousing and storage solutions worldwide.

5 Benefits of Using Reusable Collapsible Crates for Farmers and Retailers

Folding Vegetable Crates Revolutionizing the Food IndustryFolding Vegetable Crates (FVC) have revolutionized the way the food industry transports and stores its products. These lightweight, foldable, and durable crates have become a go-to for many companies worldwide, cutting costs and making logistics easier than ever before.FVC, a company that specializes in producing these crates, was founded in 2011, with the goal to make transportation of goods more efficient and eco-friendly. The company's founders, who come from a background in agricultural logistics, saw the need for a crate that would be easy to handle, fold, and store when not in use, and FVC was born.The idea was simple, but the execution was groundbreaking. With advanced technology, FVC now produces high-quality plastic crates that are strong enough to hold heavy loads of produce and can be easily folded and stacked when not in use. This innovative design saves businesses money and storage space, making it an ideal choice for the food industry.The traditional wooden crates that were used in the past were bulky and heavy, which made transportation and storage a challenge. Moreover, they deteriorated over time, requiring frequent repairs and replacement, which added to the cost. FVC comes in handy, and that's why it's regarded as an eco-friendly option because of its reusability. FVC made of polypropylene represents the ideal solution. The crates hold a considerable weight, even when stacked on top of one another, and they are durable, easy to clean and sanitize. FVC crates are available in a variety of sizes, making them adaptable to various types of produce and companies' needs. They are water-resistant and can be safely used in harsh weather conditions, whether it's hot or cold. This feature means they can be used to load or store ice or products that require refrigeration without damage. The folding Vegetable crates are easy to fold and can be stacked in as little as one-third of the space of a traditional crate. This means companies can warehouse more product in a smaller space, freeing up storage room, and optimizing use of space. The space saved is always critical, especially in restaurants and supermarkets, where space is limited.The Folding Vegetable Crates save businesses money by cutting the cost of buying wooden crates, which are costly to replace and repair regularly. Plastic is also cheaper than metal, and with the long lifespan of the FVC crates, they are an affordable investment for any food business looking to cut costs and utilizes its resources well.FVC has become the go-to option for many companies worldwide, and their products have received high praise for their efficiency, durability, and convenience. FVC has made a remarkable impact on the food industry, producing an innovative solution to a problem that many companies have struggled with for years.With over ten years of experience producing high-quality vegetable crates, FVC has become a well-established and reputable company in their field. The company's commitment to innovation, customer satisfaction, and sustainability has earned them a loyal customer base worldwide.FVC has changed the food industry forever with its revolutionary folding vegetable crates. Almost all players in the industry now recognize that using FVC has become an excellent way to reduce storage and transportation costs while also promoting sustainability. The future of the food industry depends on innovative solutions like FVC that are eco-friendly, adaptable, and cost-efficient.

Find Local Plastic Product Suppliers for Your Business

In recent years, the plastic product industry has seen significant growth, and with it, the demand for reliable, high-quality manufacturers. Among the top players in the market is a leading manufacturer of plastic products, with a reputation for excellent customer service and superior product quality.This manufacturer boasts years of experience in the production of plastic products, including packaging and containers for various industries. With state-of-the-art facilities and an experienced team of professionals, this company has emerged as a leading player in the plastic product industry, catering to the needs of customers across diverse sectors.The company’s product range includes a wide variety of packaging solutions, including airtight containers, pails, drums, jerry cans, and more. They also offer custom-designed packaging solutions to cater to the unique needs of their clients, ensuring that their products are packaged and delivered safely and in optimal condition.Apart from packaging solutions, the company also boasts expertise in manufacturing and delivering high-quality plastic products. With an extensive range of products in different sizes and shapes, they cater to the needs of various industries, including pharmaceuticals, food processing, agriculture, automotive, and household goods.The company’s core focus is on providing unparalleled value to its clients, by delivering top-quality products at competitive prices. Their products are designed to meet strict quality standards, and every item goes through rigorous quality checks to ensure they meet the required specifications.The company has invested in modern equipment to help them achieve their high-quality standards, including state-of-the-art injection molding machines, thermoforming machines, and extruders. Their production facilities are equipped with modern technology to help ensure that the products they deliver are of the highest quality, and they can execute orders of any size and complexity.The team behind this company is made up of highly skilled professionals who are passionate about delivering top-quality service to their clients. The company prides itself on its commitment to providing excellent customer service, and their team works closely with clients to help them identify their needs and provide the best solutions possible.Their expertise in the industry has helped them build long-term relationships with their clients, who rely on them for consistent and reliable delivery of high-quality products. They have established themselves as a trusted brand, thanks to their commitment to quality, timely delivery, and excellent customer service.Apart from their core business, the company also focuses on sustainability and environmental responsibility. They have implemented measures to reduce waste and recycle materials, reducing the environmental impact of their operations. As a socially responsible company, they are committed to ensuring that they are positively contributing to the community and environment.In conclusion, the plastic product industry is highly competitive, and for companies to emerge as trusted leaders, they must consistently deliver top-quality products and services. This leading manufacturer has achieved just that, thanks to their commitment to quality, industry expertise, and exceptional customer service. They are poised to continue their growth trajectory and maintain their position as a top player in the plastic product industry.

Top Characteristics and Benefits of HDPE Plastic Pallets Revealed

Title: HDPE Plastic Pallets: A Sustainable and Versatile Solution in Modern Logistics Introduction (100 words):In today's fast-paced world, efficient and sustainable logistics solutions have become paramount for businesses seeking to streamline their operations. HDPE Plastic Pallets (brand withheld) offer a versatile, durable, and eco-friendly alternative to traditional wooden pallets. These pallets, made from high-density polyethylene (HDPE), possess several advantages such as increased longevity, resistance to moisture and chemicals, and ease of recycling. With their wide-ranging applications in various industries, HDPE Plastic Pallets are revolutionizing logistics practices globally, optimizing supply chain management, and reducing environmental footprint.Body:1. Exploring the Features and Benefits of HDPE Plastic Pallets (200 words):HDPE Plastic Pallets are designed to provide utmost reliability and durability in industrial settings. With their exceptional resistance to impact, moisture, and chemicals, these pallets are capable of withstanding demanding conditions, offering a longer lifespan compared to traditional wooden pallets. Moreover, HDPE Plastic Pallets are easier to clean and maintain, ensuring hygienic transportation of goods, particularly in industries such as food and pharmaceuticals. This feature significantly reduces the risk of cross-contamination and product damage, guaranteeing the integrity of the supply chain.The versatility of HDPE Plastic Pallets is another key feature that sets them apart. Their ability to be customized for various storage and transportation needs, including different sizes, shapes, and load capacities, make these pallets suitable for a wide range of applications across industries. From heavy machinery to delicate electronics, these pallets can securely and efficiently handle diverse products.Furthermore, the lightweight nature of HDPE Plastic Pallets offers businesses significant cost-saving advantages. Reduced weight means lower transportation costs, enhanced fuel efficiency, and minimal strain on workers when handling or manipulating the pallets. Additionally, HDPE Plastic Pallets do not harbor pests, fungi, or mold, decreasing the risk of product contamination and improving overall safety standards.2. Environmentally Friendly and Sustainable Solution (200 words):One of the most prominent benefits of HDPE Plastic Pallets is their positive impact on the environment. Unlike wooden pallets, which require frequent replacement due to degradation, HDPE Plastic Pallets have a longer lifespan and can be recycled into new pallets at the end of their useful life. This recycling process reduces waste generation while conserving resources.By adopting HDPE Plastic Pallets, companies can contribute significantly to reducing deforestation, as no trees are felled in the production of these pallets. This proactive step aligns with the growing global emphasis on sustainability and responsible sourcing.In addition to sustainability, HDPE Plastic Pallets also address safety concerns often associated with wooden pallets. Wooden pallets may have exposed nails or splinters, posing risks to workers and products. In contrast, HDPE Plastic Pallets are designed to be smooth, sturdy, and free of any protruding hazards, creating a safer work environment.3. Industry Applications and Global Adoption (200 words):HDPE Plastic Pallets have gained significant traction across a wide range of industries and countries. In the automotive sector, these pallets have proven to be an invaluable solution due to their load-bearing capacity, chemical resistance, and ability to withstand extreme temperatures. Similarly, in the food industry, the hygienic nature of HDPE Plastic Pallets makes them indispensable for the transportation of perishable goods and compliance with strict quality and safety standards.The pharmaceutical industry also greatly benefits from HDPE Plastic Pallets due to their inert nature, ensuring the integrity and safety of pharmaceutical products during transportation and storage. Other industries, such as retail, logistics, and agriculture, are also increasingly embracing HDPE Plastic Pallets for their durability, versatility, and sustainability credentials.In conclusion, HDPE Plastic Pallets are revolutionizing modern logistics practices by offering a sustainable, versatile, and durable alternative to traditional wooden pallets. These pallets enhance supply chain efficiency, reduce environmental footprint, and improve overall safety standards. With their wide-ranging applications across various industries, HDPE Plastic Pallets have become an essential component of modern-day logistics, ensuring seamless transportation of goods while minimizing the impact on the planet.

Discover the Top Steel Pallet Manufacturers in the Market

Steel Pallet Manufacturers, a leading company in the manufacturing of high-quality steel pallets, continues to revolutionize the logistics and supply chain industry. With their commitment to innovation, sustainability, and customer satisfaction, they have positioned themselves as a sought-after provider in the market.As the demand for efficient and eco-friendly packaging solutions grows, Steel Pallet Manufacturers has emerged as a reliable partner for companies across various sectors. By utilizing state-of-the-art technology and an unwavering focus on product excellence, they have established themselves as industry pioneers.Founded in {year}, Steel Pallet Manufacturers has always placed emphasis on maintaining robust relationships with their clients. They believe in collaborative partnerships that promote mutual growth and long-term success. By integrating client feedback into their design and manufacturing processes, they ensure their products address the unique requirements of each customer.One of the key differentiators of Steel Pallet Manufacturers is their commitment to sustainability. Recognizing the environmental impact of traditional packaging materials, the company aims to provide greener solutions that reduce waste and contribute to a circular economy. Their steel pallets are designed for reuse, reducing the need for single-use packaging options.Furthermore, Steel Pallet Manufacturers prioritizes energy efficiency in its manufacturing process. By implementing advanced technologies and best practices, they strive to minimize their carbon footprint and promote responsible production methods. This dedication to sustainability has positioned them as a preferred choice for companies looking to align with environmentally conscious partners.Steel Pallet Manufacturers' product range is diverse, catering to a wide variety of industries. Their steel pallets are renowned for their durability, dimensional accuracy, and ability to withstand heavy loads. Customization options allow clients to tailor the pallets to their unique needs, ensuring seamless integration into their operations.The company's commitment to innovation is evident in their continuous product development efforts. By staying up-to-date with the latest industry trends and advancements, Steel Pallet Manufacturers consistently introduces new features and designs to enhance their product offerings. This adaptability has cemented their reputation as a forward-thinking industry player.Steel Pallet Manufacturers' dedication to quality is proven through their strict quality control measures. Each pallet undergoes rigorous testing to ensure it meets the highest standards of strength, stability, and safety. The company complies with all relevant industry regulations and certifications, making them a reliable partner for any organization.Another aspect that sets Steel Pallet Manufacturers apart is their exceptional customer service. With a team of knowledgeable and experienced professionals, they provide comprehensive support throughout the entire customer journey. From initial inquiries to post-sales assistance, the company prioritizes prompt and efficient communication to foster strong client relationships.As Steel Pallet Manufacturers continues to grow, they are expanding their global presence. Their commitment to customer satisfaction, sustainability, and innovation has garnered international recognition, making them a preferred choice for companies seeking reliable packaging solutions.In conclusion, Steel Pallet Manufacturers' unwavering dedication to quality, sustainability, and customer satisfaction has positioned them as an industry leader. Through their innovative designs, commitment to environmental responsibility, and exceptional customer service, they continue to revolutionize the logistics and supply chain industry. As they consistently adapt to evolving customer needs and industry trends, Steel Pallet Manufacturers remains at the forefront of providing efficient and eco-friendly packaging solutions.

Plastic Produce Crates: An Essential Solution for Efficient Storage and Transportation

Title: Sustainable Solution: Plastic Produce Crates Revolutionize the MarketIntroduction:In a world where sustainability and environmental consciousness are becoming paramount, companies are seeking innovative approaches to reduce waste and promote eco-friendly practices. One such company is at the forefront of this movement, pioneering plastic produce crates that are revolutionizing the market. By offering a sustainable alternative to traditional packaging methods, these crates not only protect produce but also contribute to a greener future.Section 1: The Challenge of Traditional Packaging SolutionsFor decades, the produce industry has relied heavily on single-use packaging materials such as cardboard boxes and disposable plastics. Although these methods have been efficient, they have contributed significantly to landfill waste and environmental degradation. Recognizing the need for a solution that balanced functionality with long-term sustainability, {} (remove brand name if given) decided to engineer an eco-friendly alternative.Section 2: The Innovation: Plastic Produce CratesAddressing the shortcomings of traditional packaging, innovative plastic produce crates provide a reusable and durable solution with a significantly lower environmental footprint. Made from recycled and recyclable materials, these crates reduce waste generation while ensuring the safe transportation and storage of fruits and vegetables.Section 3: Promoting SustainabilityThis groundbreaking product offers numerous environmental benefits. Firstly, its reusability reduces the demand for single-use packaging materials, minimizing the strain on natural resources. Additionally, these crates can be recycled at the end of their lifecycle, further reducing waste. When compared to traditional packaging, such as cardboard boxes, the lifespan and durability of plastic crates reduce the need for frequent replacements and contribute to overall resource conservation.Section 4: Enhanced Food SafetyApart from environmental advantages, plastic produce crates prioritize food safety. Built with features like smooth surfaces and rounded corners, the crates prevent damage to produce during transit. This reduces the likelihood of contamination and loss, ensuring consumers receive fresh and healthy products. Furthermore, the crates' sturdy design minimizes the risk of collapsed packaging, adding an extra layer of safety during transportation.Section 5: Cost-Efficiency and LogisticsPlastic produce crates not only benefit the environment and food safety but also provide substantial advantages in terms of cost-efficiency and logistics. Due to their sturdy construction, these crates last longer than traditional packaging, resulting in fewer replacements and increased savings for businesses. The standardized dimensions allow for easy stacking, optimizing storage space and simplifying logistical operations. Furthermore, these crates can be easily cleaned and disinfected, reducing the chances of bacterial contamination.Section 6: Widespread AdoptionThe eco-friendly appeal and practicality of plastic produce crates have garnered attention from retailers, distributors, and producers alike. Key players in the industry are embracing this sustainable solution, recognizing its potential to reduce environmental impact and meet consumer demands for sustainable packaging. As the momentum continues to grow, several leading supermarkets and grocery chains have already implemented the use of these crates.Section 7: Supporting a Circular EconomyBy choosing to use plastic produce crates, companies are actively participating in the circular economy by reducing waste and promoting a sustainable business model. The ability to reuse, recycle, and extend the life cycle of these crates aligns with the principles of a circular economy, where materials are reused and repurposed, reducing the burden on landfills and minimizing the consumption of virgin resources.Conclusion:The introduction of plastic produce crates marks a significant step towards a sustainable future in the packaging industry. These environmentally-friendly alternatives are reshaping the market by promoting eco-conscious practices, reducing waste, and ensuring the safe transportation of produce. As the demand for sustainable packaging solutions continues to rise, the adoption of plastic produce crates provides a promising pathway for building a greener and more efficient supply chain.