Plastic Fabrication Companies: How to Choose the Right Manufacturer for Your Needs

By:Admin

Introduction:

Plastic fabrication is an integral part of numerous industries, ranging from construction and automotive to healthcare and packaging. The demand for high-quality plastic products has necessitated the development of reliable and innovative plastic fabrication companies. In this article, we will explore the latest trends in the plastic fabrication industry and their impact on the overall growth of the sector.

I. Technological Advancements Boost Efficiency and Precision

In recent years, plastic fabrication companies have embraced technological advancements to streamline their manufacturing processes. Advanced computer numerical control (CNC) machines enable precise and efficient cutting, shaping, and molding of plastic materials. These machines, combined with powerful simulation software, have revolutionized the design and production phases. With reduced production times and improved accuracy, plastic fabrication companies are able to meet the evolving needs of their clients.

II. Focus on Sustainable Practices and Materials

The growing concern for the environment has contributed to a shift in the practices and materials used by plastic fabrication companies. Increasingly, companies are adopting sustainable manufacturing practices such as recycling and reusing plastic waste generated during the fabrication process. Moreover, there is a growing preference for biodegradable and plant-based plastics as alternatives to traditional petroleum-based plastics. This shift towards sustainable practices not only aligns with environmental goals but also enhances the overall brand image of plastic fabrication companies.

III. Customization and Design Flexibility

One of the key trends in the plastic fabrication industry is the growing demand for custom-designed plastic products. Plastic fabrication companies are investing in design capabilities to cater to unique client requirements. With advancements in computer-aided design (CAD) software, these companies can work closely with clients to bring their concepts to life. Customization and design flexibility have allowed plastic fabrication companies to address diverse needs across industries, giving them a competitive edge in the market.

IV. Automating Assembly Processes

Automation and robotics are making their way into the plastic fabrication industry, offering increased efficiency and improved quality control. Automated assembly processes enable faster production cycles, reduce labor costs, and help minimize errors. Robotic systems are capable of handling complex tasks such as precise gluing, welding, and fastening, resulting in higher-quality end products. By embracing automation, plastic fabrication companies can optimize their operations to meet the ever-growing demand for plastic products.

V. Collaboration and Partnerships

To stay competitive in the dynamic plastic fabrication industry, companies are forging strategic partnerships and collaborations. Collaboration with material suppliers, component manufacturers, and industry experts enables companies to access specialized knowledge and resources. Joint efforts to develop innovative technologies and materials accelerate the pace of progress within the industry. These partnerships not only foster growth but also facilitate knowledge exchange and continuous improvement.

Conclusion:

The plastic fabrication industry is witnessing significant transformation as companies adopt new technologies, sustainable practices, and innovative design techniques. Technological advancements have increased efficiency and precision, enabling plastic fabrication companies to cater to diverse client requirements. Collaboration and partnerships have also played a crucial role in driving innovation and fostering growth. Moreover, the industry's commitment to sustainability is propelling the development of eco-friendly materials and practices. As the demand for plastic products continues to rise, plastic fabrication companies are well-positioned to leverage these trends and drive future growth.

Company News & Blog

Guide to Choosing the Best Material for Tote Bags

: How to Choose the Best Fabric for Custom Tote BagsCustom tote bags are a versatile and eco-friendly way to promote your brand or business. They can be used as promotional giveaways, swag bags at events, or even as retail packaging. Tote bags are available in a wide range of materials, each with its own unique properties and advantages. In this blog, we’ll explore the most common materials used for tote bags and help you choose the best fabric for your custom manufacturing needs in China.1. PolypropylenePolypropylene is a popular choice for custom tote bags because it is affordable, lightweight, and durable. It is also resistant to water, stains, and mildew. Polypropylene tote bags are easy to clean and can be reused multiple times. They are commonly used for grocery shopping, beach outings, and other outdoor activities. Polypropylene is also an excellent choice for custom manufacturing in China because it is easy to cut, sew, and print on.2. CottonCotton tote bags are a classic choice for promotional merchandise. They are soft, comfortable, and eco-friendly. Cotton is a natural fiber that is biodegradable and renewable. Cotton tote bags are ideal for carrying light items such as books, clothing, and accessories. They are also great for screen printing and embroidery. However, cotton is not water-resistant and can shrink if not cared for properly.3. PolyesterPolyester tote bags are durable, lightweight, and water-resistant. They are a popular choice for outdoor activities such as sports events and camping trips. Polyester is a synthetic fiber that is easy to clean and resistant to fading and wrinkles. Polyester tote bags can also be printed with vibrant colors and intricate designs. However, polyester is not biodegradable and can take hundreds of years to decompose.4. NylonNylon tote bags are similar to polyester bags in terms of properties and uses. They are lightweight, durable, and water-resistant. Nylon is a synthetic fiber that is easy to clean and resists shrinking and wrinkles. Nylon tote bags are ideal for travel, commuting, and outdoor activities. Nylon is also a popular choice for custom manufacturing in China because of its versatility and affordability.5. CanvasCanvas tote bags are thick and durable. They are ideal for carrying heavy items such as groceries and books. Canvas is a natural fiber that is biodegradable and renewable. Canvas tote bags are also easy to customize with screen printing and embroidery. However, canvas is not water-resistant and can be prone to staining.6. JuteJute tote bags are eco-friendly and biodegradable. Jute is a natural fiber that is renewable and sustainable. Jute tote bags are durable and can carry heavy items such as groceries and books. Jute is also easy to print on with vibrant colors and designs. However, jute is not water-resistant and can be prone to shrinking and stretching.7. PVCPVC tote bags are made from a synthetic material that is durable and water-resistant. PVC is easy to clean and resistant to stains and mildew. PVC tote bags are ideal for outdoor activities such as beach outings and camping trips. However, PVC is not biodegradable and can take hundreds of years to decompose. PVC also has a negative environmental impact, making it a less eco-friendly option.In conclusion, choosing the best fabric for your custom tote bags depends on your specific needs and preferences. If you are looking for an affordable and versatile option, polypropylene is a great choice. If you want a natural and eco-friendly option, cotton or jute may be ideal. If you need a water-resistant option for outdoor activities, polyester or nylon are perfect. PVC should be avoided if you want to minimize your environmental impact. Custom manufacturing in China offers a wide range of options for tote bags, so choose the fabric that best meets your criteria and brand image.

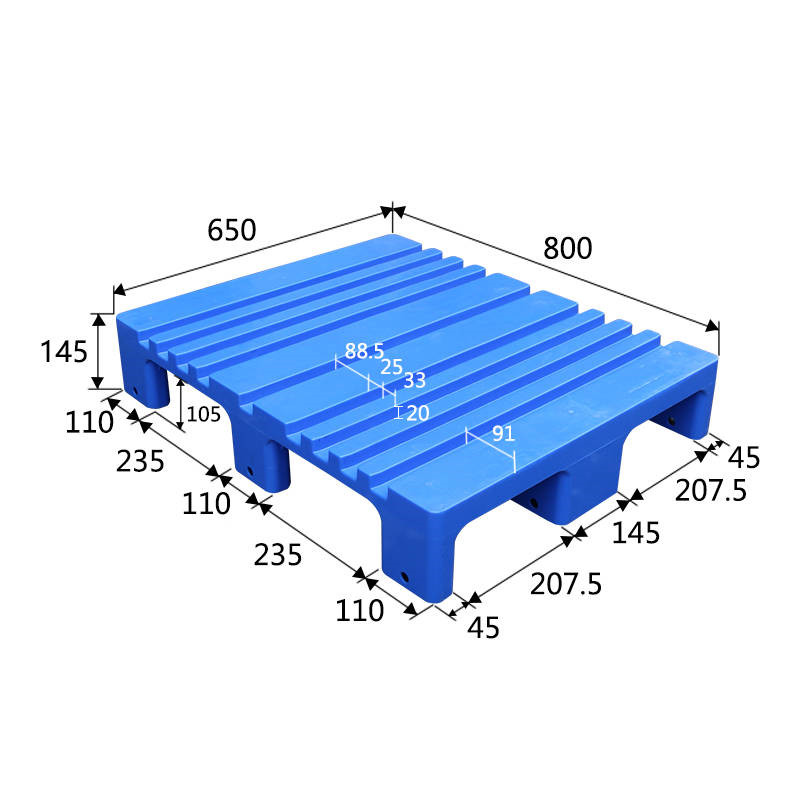

High-Quality, Durable Plastic Pallet for Efficient Running Operations - The Ultimate Guide

In today’s world, where sustainability and eco-friendliness have become the buzzwords, companies are looking for ways to reduce their carbon footprint and make their processes more environmentally friendly. Many companies are turning to plastic pallets for their logistics needs as they are durable, hygienic, and can be reused multiple times. One such company producing plastic pallets is the 6 Runners Plastic Pallet - a leading manufacturer and supplier of high-quality plastic pallets.The 6 Runners Plastic Pallet, which was established in 1966 in Japan, has become a popular choice for companies looking for durable and long-lasting logistics solutions. They offer a comprehensive range of plastic pallets that are suitable for various industries, including food, beverage, pharmaceuticals, and retail.The plastic pallets produced by the 6 Runners Plastic Pallet is made of high-density polyethylene (HDPE), which makes them sturdy and strong. They are designed to carry heavy loads and are resistant to wear and tear, making them ideal for long-term use. This makes them an excellent investment for companies that need reliable logistics solutions.Apart from being durable, the plastic pallets produced by the 6 Runners Plastic Pallet are also lightweight. This means that they are easy to handle and transport. Additionally, they are also easy to clean and maintain, making them a more hygienic option compared to wood or metal.The 6 Runners Plastic Pallet is committed to sustainability and reducing environmental impact. Their plastic pallets are made from 100% recyclable materials, which means that they can be reused and repurposed multiple times. This reduces waste and conserves natural resources. The company also ensures that their production processes are environmentally responsible and comply with all regulations and standards.The benefits of using plastic pallets from the 6 Runners Plastic Pallet are many. They are resistant to moisture, mould, and bacteria, which makes them ideal for industries such as food and pharmaceuticals, where hygiene is critical. They are also stackable, which means that they take up less space, making them an excellent option for companies with limited storage space.In addition to their standard range of plastic pallets, the 6 Runners Plastic Pallet also offers custom solutions to meet the specific needs of their clients. This includes pallets in various sizes, shapes, and colours. They also offer printing and branding services, which means that companies can customize their pallets with logos and other branding elements.The 6 Runners Plastic Pallet has a robust distribution network, which ensures that their plastic pallets are readily available to clients. Their products are distributed worldwide, and they have a strong presence in Asia, Europe, and North America. With over 50 years of experience in the industry, the 6 Runners Plastic Pallet has built a reputation for quality, reliability, and customer service.In conclusion, the plastic pallets produced by the 6 Runners Plastic Pallet offer a sustainable and environmentally friendly logistics solution. They are durable, lightweight, and hygienic, making them an ideal option for various industries. With their focus on sustainability and compliance with regulations, the 6 Runners Plastic Pallet is a trusted partner for companies looking for a reliable logistics solution.

Slow Food Philosophy: Bread Recipes, Nutrition Info and Farming Practices

Title: Embracing Slow Food Philosophy: Bread Recipes and Sustainable LifestylesIntroduction (100 words):In today's fast-paced world, it's easy to overlook the impact our food choices have on our health and the environment. However, by adopting a slow food philosophy, we can reconnect with the food we consume and make conscious decisions that promote sustainable living. This blog post aims to delve into the importance of slow food philosophy, present delicious bread recipes that reflect this mindset, and shed light on the detrimental use of plastic bread racks in the food industry.Understanding Slow Food Philosophy (200 words):The essence of slow food philosophy lies in savoring wholesome meals made from locally sourced, organic, and sustainable ingredients. By embracing this mindset, we advocate for fair and transparent farming practices. Slow food encourages us to take the time to connect with the origin of our food, its nutritional benefits, and the positive impact it has on our bodies. This approach fosters a profound appreciation for the flavors and cultural heritage associated with traditional recipes.Delicious Bread Recipes (300 words):1. Rustic Whole Grain Sourdough - Requiring only four ingredients, this recipe showcases the art of making bread from scratch. The long fermentation process of sourdough baking enhances flavor and promotes good gut health.2. Ancient Grain Ciabatta - Combining ancient grains like spelt, kamut, and einkorn, this ciabatta recipe offers a delightful twist on a classic bread. Ancient grains provide a variety of nutritional benefits while preserving biodiversity.3. Vegan Pumpkin Seed Loaf - Packed with essential nutrients, this vegan-friendly bread utilizes pumpkin seeds for a crunch and flavor boost. By eliminating animal products, we contribute to reducing our carbon footprint.The Plastic Bread Rack Problem (300 words):While our focus here is on nourishing and sustainable bread recipes, it is vital to acknowledge the concerning issue of plastic bread racks prevalent in the food industry. Plastic bread racks, although seemingly innocuous, contribute significantly to plastic pollution. These racks are often discarded after a single usage, ending up in landfills or polluting our oceans.Alternatives to Plastic Bread Racks (200 words):To combat this environmental problem, it is essential for bakeries and food establishments to explore sustainable alternatives to plastic bread racks. Some potential options include:1. Reusable Rack Systems: Investing in durable and long-lasting racks that can be easily cleaned and reused reduces plastic waste.2. Biodegradable Materials: Exploring packaging solutions crafted from biodegradable or compostable materials ensures they won't harm the environment in the long run.3. Creative Display Methods: Ditching conventional bread racks altogether and opting for more eco-friendly display options, such as wooden shelves or sustainable bamboo racks, adds a touch of uniqueness.Conclusion (100 words):Embracing the slow food philosophy not only promotes healthier and tastier eating habits but also serves as a reminder of our responsibility towards the environment. By enjoying bread recipes that prioritize sustainability, we contribute to minimizing our carbon footprint. Additionally, addressing the harmful use of plastic bread racks in the food industry is crucial to creating a greener future for generations to come. Let us remember: we are what we eat, so let's make sure we choose foods that nourish us while also protecting our planet.

High-Capacity, Versatile Plastic Pallets: Ideal for Export and Pharmaceutical Industries

Title: Innovative Plastic Pallets: Revolutionizing Export Packaging SolutionsIntroduction:Plastic pallets have gained significant popularity in recent years, revolutionizing the export packaging industry due to their durability, cost-effectiveness, and eco-friendliness. This article will explore the load capacity, size, and unique applications of plastic pallets, especially focusing on euro plastic pallets and their contribution to transforming the export packaging sector.Company Introduction: [Insert Company Name][Company Name] is a leading manufacturer and supplier of high-quality plastic pallets. With a strong focus on innovation, we aim to provide sustainable, safe, and efficient packaging solutions for various industries. Our extensive range of plastic pallets ensures superior loading capacity, durability, and traceability, making them the ideal choice for export shipments.Load Capacity of Plastic Pallets:One of the key advantages of plastic pallets is their remarkable load capacity. Unlike their traditional wooden counterparts, plastic pallets are engineered to withstand heavy loads without warping, cracking, or breaking. With load capacities ranging from 1000kg to 2000kg, these versatile pallets are suitable for a wide range of applications, including the transportation of heavy machinery, automotive parts, pharmaceuticals, and more.Specialized Sizes for Different Industries:Plastic pallets come in various sizes to accommodate different industry requirements. Standard sizes include 1200x1000mm and 800x1200mm, which are widely used for general export purposes. Additionally, custom sizes can be manufactured to cater to specific industry needs, ensuring maximum efficiency and utilization of storage space during transportation.Export-Specific Euro Plastic Pallets:Euro plastic pallets have emerged as a popular choice for export shipments due to their standardized dimensions and compatibility with various transportation modes. These pallets adhere to the European Pallet Association (EPAL) standards, guaranteeing seamless integration within the global supply chain network. Euro plastic pallets typically measure 1200x800mm, making them an ideal choice for exporting goods to European countries.Advantages of Euro Plastic Pallets:Euro plastic pallets offer several unique advantages, making them the preferred choice for export-oriented businesses:1. Traceability: Euro plastic pallets are marked with identifiable logos and codes, ensuring easy tracking and traceability throughout the shipping process. This enables efficient inventory management and reduces the risk of lost or misplaced pallets.2. Hygiene and Compliance: Euro plastic pallets are easy to clean, reducing the risk of contamination during the transportation of pharmaceuticals and food products. They also comply with international regulations on sanitation, making them suitable for industries with strict hygiene requirements.3. Improved Ergonomics: These pallets are designed with ergonomic features such as anti-slip surfaces and reinforced corners, ensuring safe handling during loading and unloading processes. This reduces the risk of workplace injuries and enhances overall operational efficiency.Expanding Opportunities for Sustainable Export Packaging:Plastic pallets not only offer enhanced durability and load capacity but also contribute to environmental sustainability. Unlike wooden pallets, plastic pallets are reusable, recyclable, and do not require fumigation for international shipments. By opting for plastic pallets, businesses can reduce their carbon footprint and contribute to a greener future.Conclusion:Plastic pallets, with their exceptional load capacity, specialized sizes, and unique applications, have transformed the export packaging industry. Euro plastic pallets, in particular, have gained significant traction due to their adherence to global standards. As [Company Name] continues to innovate, our robust range of plastic pallets ensures safe and eco-friendly transportation of goods across various industries, revolutionizing the export packaging sector.

FDA-Approved Plastic Pallets at Great Prices: Lightweight, Nestable, and Recyclable Options Available

Container Pallets: A Perfect Solution for Shipping NeedsIn today's world of global trade, container pallets have become an essential tool for businesses of all sizes. Container pallets are specifically designed to meet the needs of shipping containers and are perfect for managing goods in transportation.Container pallets are available in various sizes, materials, and types. The most common material for container pallets is plastic, and the two most popular types are standard pallets and nesting pallets.A standard container pallet is designed to be sturdy and capable of carrying heavy loads. They are perfect for transportation using standard shipping containers and can handle a wide range of products, from machinery to medical equipment. The use of standard container pallets ensures goods remain secure and stable throughout their journey.Nesting container pallets, on the other hand, are designed to interlock when stacked, saving valuable space during transportation. Nesting pallets are perfect for businesses looking for more cost-effective options while transporting light to medium loads.No matter what type of container pallets you choose, one thing is certain: each one is designed to meet the specific needs of transporting your goods safely and securely.At Global Industrial Equipment, we offer a wide range of container pallets to meet the varied needs of businesses. Our container pallets are sturdy, durable, and designed to meet the highest quality standards.One of our most popular container pallets is the Container Pallet Deck, a standard container pallet that can support a heavy load of up to 2,500 pounds. The deck features 9 legs for maximum stability and durability while also accommodating truck and forklift entry. The Container Pallet Deck is also available in lightweight versions, making it perfect for businesses looking for a more cost-effective option while still providing maximum durability.If you are looking for a more compact and space-saving option, our nestable container pallets are an excellent choice. Our Nestable Shipping Plastic Pallets are designed to interlock, saving valuable space during transportation. The Nestable Pallets can support a load capacity of up to 2,000 pounds and are perfect for businesses looking for a more cost-effective option without compromising on quality.In conclusion, container pallets are an essential tool for businesses looking to transport their goods efficiently and safely. Whether looking for standard or nesting options, Global Industrial Equipment has a comprehensive range of container pallets to suit every need.So, if you are looking for high-quality container pallets, we are here to help. Visit our website today, and let us help you find the perfect solution for your shipping needs!

Unveiling the Harmful Effects of Plastic on the Environment

in your article.The Problem with Plastics: Finding Sustainable Solutions from Plastic Parts SuppliersPlastics have become an integral part of our everyday lives. From food packaging to medical equipment, these materials have proven their durability and flexibility. However, the convenience that plastics offer comes at an environmental cost.Plastic waste has become a global problem, with plastic debris now littering oceans and polluting ecosystems. A report by the World Economic Forum revealed that by 2050, there could be more plastics in the oceans than fish. Governments, organizations, and individuals are coming together to address this issue, and one key player in this effort is the plastic parts suppliers.Plastic parts suppliers are companies that specialize in the manufacturing and distribution of plastic components that are used in various industries such as automotive, consumer goods, and construction. These suppliers have a critical role to play in finding sustainable solutions to the plastic waste problem.One way plastic parts suppliers can contribute to environmental sustainability is by using recycled plastics. Recyclable plastics, such as polyethylene terephthalate (PET), can be used to make new products. The use of recycled plastics reduces the amount of plastic sent to landfills and helps to conserve natural resources.Another way plastic parts suppliers can promote sustainability is by reducing the amount of plastic used in their products. Lightweight plastics, such as polycarbonate and nylon, are being used increasingly in automotive and consumer goods. These materials are not only more energy-efficient but also require fewer resources to produce.In addition to minimizing plastic waste, plastic parts suppliers can also contribute to environmental sustainability by adopting eco-friendly manufacturing practices. These practices include reducing energy consumption, minimizing water usage, and implementing waste reduction programs in their production processes.The role of plastic parts suppliers in promoting sustainability does not end there. These companies can also encourage their customers to adopt eco-friendly practices. By providing them with sustainable alternatives such as biodegradable plastics or reusable packaging solutions, plastic parts suppliers can support their customers in achieving their sustainability goals.In conclusion, plastics are an essential component of modern life, but their impact on the environment cannot be ignored. Plastic parts suppliers have a critical role to play in addressing this issue. By using recycled plastics, reducing plastic usage, adopting eco-friendly manufacturing practices, and providing sustainable alternatives to their customers, these companies can contribute significantly to environmental sustainability. Together, we can all work towards a cleaner, healthier planet.

Discover Top Plastic Pallet Box Manufacturers for Efficient Storage Solutions

Plastic Pallet Box Manufacturers Continue to Innovate and Improve Efficiency in Logistics IndustryIn an increasingly globalized world, the logistics industry plays a crucial role in ensuring the smooth movement of goods and materials from one place to another. An essential component of this process is packaging, which must be reliable, durable, and efficient in order to protect the cargo and streamline the transportation process. Plastic pallet box manufacturers have emerged as key industry players, continuously innovating and improving their products to meet the demands of the logistics industry.As one of the leading plastic pallet box manufacturers, Company Name has played an instrumental role in providing the market with cutting-edge solutions. With their commitment to quality, durability, and sustainability, they have secured a strong position in the industry. By adapting to evolving market needs and leveraging the latest technological advancements, Company Name continues to revolutionize the way goods are packaged and transported.Company Name's plastic pallet boxes are renowned for their robust construction, high load capacity, and stackability, allowing for safe and efficient storage and shipping. The use of durable plastics ensures that these pallet boxes can endure the rigors of transportation, protecting the goods inside from damage and ensuring a seamless supply chain process. Additionally, their stackable design maximizes storage efficiency, enabling businesses to optimize their warehouse space and minimize operational costs.Furthermore, Company Name is committed to sustainability and environmental responsibility. They understand the importance of reducing waste and the impact of plastic on the environment. In response to this concern, they have developed a range of eco-friendly plastic pallet boxes made from recycled materials. These boxes not only provide the same high-quality performance but also contribute to the circular economy by reducing the reliance on virgin materials.Innovative features are a hallmark of Company Name's plastic pallet boxes. By incorporating state-of-the-art technologies such as RFID and GPS tracking systems, they enable businesses to have real-time visibility and control over their supply chain. This advanced tracking system allows for efficient inventory management, minimizing the risk of loss or theft, and ensuring timely delivery of goods to their destinations.Moreover, Company Name is deeply committed to meeting the diverse needs of their customers. They offer a wide range of pallet box sizes and configurations, customized to specific requirements. Whether it is for storing perishable goods, fragile items, or hazardous materials, Company Name has a solution that meets the industry standards and regulatory requirements.It is worth noting that Company Name's contribution extends beyond manufacturing outstanding pallet boxes. They have also established strong partnerships with logistics providers, distributors, and retailers to offer comprehensive end-to-end solutions. By collaborating with key stakeholders, they ensure that the entire supply chain is optimized for efficiency and cost-effectiveness.In conclusion, plastic pallet box manufacturers like Company Name play a pivotal role in the logistics industry's effective functioning. Their continuous innovation, commitment to quality, and environmental sustainability position them as industry leaders. By providing robust, reliable, and customizable packaging solutions, they enable businesses to streamline their operations, reduce costs, and ensure the safe transportation of goods. As the demand for efficient logistics solutions continues to grow, plastic pallet box manufacturers like Company Name will remain key players, propelling the industry forward with their ability to adapt and innovate.

Must-Have Moving Boxes for a Smooth Relocation

Title: Efficient and Hassle-Free Moving Solutions with Superior Packing BoxesIntroduction:In today's fast-paced world, moving homes or offices has become an essential part of our lives. A reliable and efficient moving company can greatly ease the stress and challenges associated with such transitions. One notable player in this industry is "Boxes To Pack Moving," a renowned leader that specializes in providing top-quality packing boxes and moving solutions. With their dedication to excellence and exceptional customer service, the company has firmly established itself as a go-to option for individuals and businesses alike.State-of-the-Art Packing Boxes:Boxes To Pack Moving offers a comprehensive range of packing boxes for a variety of moving needs. Their top-of-the-line boxes are meticulously designed to ensure maximum durability and protection during transportation. Made from high-quality materials, these boxes provide excellent resistance to crushing and tears, safeguarding fragile items, valuables, and belongings of all sizes.The company's extensive selection includes boxes specifically tailored for books, clothing, kitchenware, electronics, artwork, and more. This wide variety enables customers to efficiently pack their possessions while ensuring utmost safety and organization. Moreover, every box is engineered with convenient handles for easy lifting and strategic labeling areas for efficient sorting and unpacking at the destination.Eco-Friendly Approach:Boxes To Pack Moving not only prioritizes customer satisfaction but also places great importance on environmental responsibility. In line with their vision of sustainable moving solutions, the company utilizes eco-friendly and recyclable materials in their packing boxes. This commitment helps reduce waste and minimizes the impact on the environment, making them an ideal choice for individuals and businesses seeking eco-conscious moving solutions.Customized Services:Understanding that each move is unique, Boxes To Pack Moving offers personalized services tailored to meet the specific requirements of their customers. They provide assistance in determining the quantity and types of packing boxes needed, ensuring a hassle-free and efficient packing experience. With their expertise, customers can optimize their moving process, making it smoother and more organized.Unwavering Commitment to Customer Satisfaction:Boxes To Pack Moving is committed to delivering exceptional customer service from the start till the end of the moving journey. Their knowledgeable and friendly staff are always available to address any concerns and provide expert guidance throughout the moving process.In addition to superior packing boxes, the company goes the extra mile to offer value-added services. They provide packing tutorials and tips on their website, helping customers pack fragile items, delicate electronics, and other specific belongings with precision and care. Boxes To Pack Moving also offers prompt delivery services, ensuring customers receive their packing boxes on time, regardless of the destination.Partnerships with Businesses:Recognizing the importance of seamless commercial moves, Boxes To Pack Moving has developed strategic partnerships with businesses of all sizes. By understanding the specific requirements and challenges faced by enterprises during relocations, the company offers customized solutions that enable businesses to resume their operations quickly and efficiently. Whether it's a small office or a multinational corporation, Boxes To Pack Moving works closely with their clients to deliver tailored packing and moving services that minimize disruptions and maximize efficiency.Conclusion:With their premium packing boxes, commitment to eco-friendly practices, personalized services, and dedication to customer satisfaction, Boxes To Pack Moving stands out as a reliable and trusted partner in the moving industry. For individuals and businesses alike, their high-quality packing solutions ensure a smooth and hassle-free transition to new premises. Whether it's a local move or long-distance relocation, Boxes To Pack Moving is the go-to choice for those seeking excellence, efficiency, and peace of mind.

Durable Composite Pallets Benefiting Businesses in Shipping and Storage Industries

The composite pallet industry is growing at an accelerated pace with more consumers and manufacturers showing interest in this eco-friendly and cost-effective alternative to traditional pallets. Composite pallets are made from materials such as wood, plastic, and other recycled materials, making them both durable and sustainable. Among the leading players in this industry is a company that offers a wide range of composite pallet solutions that allow manufacturers to optimize their logistical processes.One of the major advantages of composite pallets is their low maintenance costs. They do not require as much upkeep as traditional wooden pallets, which can save businesses a considerable amount of time and money. Furthermore, composite pallets are extremely durable, ensuring that they can last a long time, even in tough manufacturing environments, and can withstand high-temperature conditions and exposure to chemicals.In addition to these benefits, composite pallets are also reusable, which significantly reduces waste and the environmental impact of the industry. Many businesses today are committed to sustainability and reducing their carbon footprint, and composite pallets are an excellent option for those who want to adopt more environmentally-friendly practices. The company behind the composite pallets takes pride in offering a product that aligns with the global effort to reduce waste and combat climate change.Another significant advantage of composite pallets is their scalability. The company’s composite pallets are designed to meet different types of logistical needs. They can be used for transporting items of different weights and sizes, making them versatile and practical. For instance, a business that wants to transport heavy machinery can use composite pallets as they can bear immense loads.Furthermore, the composite pallets come in different sizes and can be customized to suit each client's needs. With such a vast selection of composite pallets, manufacturers can choose the perfect option that aligns with their logistical needs and budget. The company's team of experts can work alongside clients to ensure that they get the best product for their requirements, even offering valuable insights based on decades of industry experience.In addition to the cost and environmental benefits, composite pallets also provide improved safety and hygiene standards. Unlike traditional wooden pallets that are prone to splintering and breakage, composite pallets are sturdy and have a smooth, non-slip surface that reduces the chances of accidents, thus improving employee safety. In addition, composite pallets are washable, and they don't hold on to moisture, which significantly reduces the risk of bacteria formation.As more businesses realize the benefits of composite pallets, the demand for these products will continue to grow. The company behind composite pallets is uniquely positioned to meet this growing demand through its innovative design, scalable and customizable products, and industry experience. Furthermore, the company’s high-quality standards ensure that clients receive a product that meets, if not exceeds, their expectations.In conclusion, composite pallets are becoming increasingly popular due to their cost-effectiveness, eco-friendly nature, improved safety, and hygiene qualities. On top of those qualities, the company's ability to provide scalable and customizable products and an experienced team of experts makes them the go-to option for manufacturers looking to optimize their logistics processes. As businesses look to reduce their expenses, as well as move towards sustainable practices, the composite pallets offered by the company serve as excellent options to achieve both of those goals.

Effective Methods to Prevent, Inhibit and Remediate Mold on Wood Pallets

Wooden pallets have been used in industries worldwide for transporting and storing goods for ages. They are economical, environmentally friendly, and reusable. However, one of the significant challenges that come with using wooden pallets is the growth of mold. Pallet mold can wreak havoc on the products being transported, leading to losses for the manufacturers.Mold growth on pallets is caused by various factors like humidity, temperature, and moisture content. Once mold growth starts, it can spread quickly, leading to a complete infestation that may render the pallets unusable. Manufacturers need to take steps to prevent, inhibit and remediate pallet mold to reduce losses and ensure product safety.Preventing Pallet MoldPreventing mold growth on wooden pallets requires manufacturers to be proactive in their approach. Here are some ways to prevent pallet mold:1. Dry pallets thoroughly: Before using wooden pallets, ensure they are thoroughly dry. Moisture is a significant contributor to mold growth, and ensuring the pallets are dry can prevent mold growth.2. Proper storage: If pallets are not in use, they should be stored in a dry, well-ventilated area. If stored outside, cover the pallets with a tarp to prevent water from getting in.3. Use mold-resistant pallets: Some pallets come specifically treated with chemicals like borates to inhibit mold growth.Inhibiting Pallet MoldManufacturers may not always be able to prevent mold growth on pallets. However, inhibiting mold growth can help reduce losses. Here are some ways to inhibit pallet mold:1. Regular cleaning: Regularly cleaning the pallets can inhibit mold growth. Use a mild cleaning solution to wash the pallets, then air dry them in a well-ventilated area.2. Use anti-microbial coatings: Anti-microbial coatings can be applied to pallets to inhibit mold growth. These coatings can be applied using a spray method or a dipping method.3. Use pallet covers: Pallet covers can be used to protect the pallets from moisture and humidity, inhibiting mold growth.Remediating Pallet MoldIf mold growth is detected on wooden pallets, remediation is necessary to prevent it from spreading. Here are some ways to remediate pallet mold:1. Surface cleaning: Use a mild cleaning solution and a brush to clean the pallet surface thoroughly. Then, air dry the pallets.2. Secondary cleaning: If the mold growth is extensive, secondary cleaning may be necessary. Use a stronger solution and a pressure washer to clean the pallets.3. Fumigation: Fumigation may be necessary for severe cases of mold growth. This involves sealing the pallets in an airtight space and using chemicals to kill the mold.In conclusion, pallet mold is a significant concern for manufacturers, but steps can be taken to prevent, inhibit and remediate it. By being proactive, manufacturers can prevent mold growth on their pallets. If mold growth occurs, inhibiting its spread and remediating it can help reduce losses and ensure product safety. Manufacturers should ensure they have a pallet mold prevention plan in place.