Discover the Benefits of Using Flat Top Pallets for Your Material Handling Needs

Flat Top Pallet Introduces Revolutionary Packaging Solution to Streamline Operations for BusinessesFor businesses looking to optimize their supply chain, Flat Top Pallet LLC has introduced a revolutionary packaging solution that further streamlines operations. With an emphasis on big box retail, the patented pallet can dramatically cut costs for shippers while improving logistics for the retailers themselves. The unique pallet design eliminates the need for unit load devices (ULDs) by utilizing oversized pallets. Thanks to the pallet's unique design, shippers can pack up to 150% more products into a truckload as opposed to a traditional pallet, effectively reducing transportation costs by up to 25%. The pallet's versatility also allows for quick de-stacking and easier loading, saving time and effort for workers.Made from durable, high-density polyethylene (HDPE) plastic, the Flat Top Pallet is superior to traditional wood pallets in volume capacity and durability. Moreover, unlike traditional wood pallets that can splinter and break, the Flat Top Pallet is long-lasting, with a lifespan of up to 10 years. This reduction in downtime and repair costs makes it an ideal choice for businesses looking to achieve efficiency and sustainability.With a goal of sustainability in mind, Flat Top Pallet emphasizes its eco-friendly manufacturing processes. The company uses 100% recycled, post-consumer materials and also recycles all manufacturing waste, reducing its carbon footprint. In addition to eliminating the need for ULDs, the company's patented design prevents product damage in transit and protects the environment by cutting down on the need for petroleum-based protective products.Andy Smith, the CEO of Flat Top Pallet, commented, "Our enhanced, durable design, combined with the unique production process we employ, makes our pallet the first choice for businesses looking to optimize their supply chains. Our customers are looking for long-lasting durability and the ability to transport more products on fewer trips. We are committed to continually innovating our designs to meet these demands."The Flat Top Pallet is available in footprints ranging from 40x48 to 48x80, with customized follow-up and maintenance services to ensure a seamless customer experience. Flat Top Pallet also works closely with logistics providers and warehousing professionals to create full-service shipping solutions tailored to each client's specific needs.The pallet is already in use with major retailers across the country, including Walmart, Target, and Home Depot. The retailers are already seeing the benefits with the pallet helping them to reduce storage and transportation costs and increase revenue, due to the increase in load size.Flat Top Pallet is the latest organization to embrace a greener approach to business, recognizing that improving supply chain efficiency goes hand-in-hand with sustainability. The company's innovative pallet design is set to revolutionize operations for businesses of all sizes.In conclusion, the Flat Top Pallet LLC is set to shake up the pallet industry with its innovative and cost-effective pallets. The unique design offers a practical and groundbreaking solution for businesses looking to reduce transportation costs and streamline the supply chain. With its high-density polyethylene plastic and top-of-the-line manufacturing process, the Flat Top Pallet is built to last and offer customers a conscious choice of an eco-friendly alternative. As businesses around the country continue to prioritize sustainability, Flat Top Pallet LLC is poised to become an integral part of the shift towards greener supply chain solutions.

Read More

SEO Title: Reliable and Versatile Pallets for Efficient Die Cutting Machines

Pallet For Die Cutting Machine Revolutionizing Efficiency in ManufacturingIn today's fast-paced manufacturing industry, companies are constantly seeking innovative solutions to streamline their production processes and boost efficiency. One such groundbreaking solution that has been making waves in the industry is the Pallet for Die Cutting Machine. This state-of-the-art technology is transforming the way companies handle die cutting operations, paving the way for higher productivity and accuracy.The Pallet for Die Cutting Machine is a versatile tool that enables manufacturers to maximize their die cutting capabilities. It is specifically designed to enhance the efficiency and precision of die cutting operations, making it an essential component for any manufacturing facility. The use of this cutting-edge pallet has proven to be a game-changer, significantly revolutionizing the industry.By eliminating the need for manual alignment and setup, the Pallet for Die Cutting Machine allows for quick and hassle-free die cutting changeovers. This translates into reduced downtime and increased productivity, enabling manufacturers to meet tight deadlines and fulfill customer orders with ease. Additionally, this revolutionary technology ensures consistent and precise die cutting results, guaranteeing high-quality outputs for every batch.The Pallet for Die Cutting Machine also enhances operator safety and ergonomics. Its user-friendly design minimizes the risk of injuries and strain associated with traditional die cutting processes. This not only provides a safer work environment for employees but also reduces the likelihood of production delays caused by accidents or injuries.One of the key features that sets this pallet apart from others in the market is its adaptability. The Pallet for Die Cutting Machine is compatible with a wide range of die cutting equipment, making it a versatile investment for manufacturers operating different machines. This adaptability allows companies to optimize their existing equipment and avoid the need for expensive upgrades or replacements, saving both time and money.Furthermore, the Pallet for Die Cutting Machine can be customized to suit specific manufacturing requirements. Its modular design allows for easy adjustments and modifications, ensuring that it is tailored to meet the unique needs of each production line. This flexibility is particularly advantageous for companies producing diverse products with varying die cutting specifications.With its advanced technology and numerous benefits, the Pallet for Die Cutting Machine is quickly gaining traction in the industry. Companies that have implemented this innovative solution have reported significant improvements in efficiency, cost-effectiveness, and product quality. By automating and optimizing die cutting processes, manufacturers can now focus on higher-value tasks, such as innovation, product development, and customer satisfaction.Company Introduction:{}, a leader in manufacturing solutions, has been at the forefront of innovation in the industry for over three decades. Committed to helping companies streamline their operations, {}, has worked tirelessly to develop cutting-edge technologies that revolutionize manufacturing processes.With a team of highly skilled engineers and technicians, {}, has successfully launched several ground-breaking solutions that have transformed the industry. The Pallet for Die Cutting Machine is just one example of their commitment to excellence and customer satisfaction.The company's dedication to research and development ensures that their products are always at the forefront of technological advancements. Constantly seeking ways to improve efficiency, productivity, and safety, {}, strives to provide manufacturers with the tools they need to stay competitive in a rapidly evolving market.In addition to their high-quality products, {}, also offers comprehensive after-sales support and training programs. Their team of experts is readily available to assist customers with installation, troubleshooting, and maintenance, maximizing the performance and longevity of their equipment.By combining innovative technology, unparalleled expertise, and a customer-centric approach, {} continues to empower manufacturers across the globe. With their Pallet for Die Cutting Machine making waves in the industry, it is clear that their commitment to revolutionizing manufacturing efficiency remains unwavering. In conclusion, the Pallet for Die Cutting Machine is a game-changer in the manufacturing industry. With its ability to streamline die cutting operations, improve productivity, and ensure consistent quality outputs, this revolutionary technology has become an invaluable asset for manufacturers worldwide. With companies like {} leading the way in innovation and customer support, the future of manufacturing looks brighter than ever.

Read More

Effective Methods to Prevent, Inhibit and Remediate Mold on Wood Pallets

Wooden pallets have been used in industries worldwide for transporting and storing goods for ages. They are economical, environmentally friendly, and reusable. However, one of the significant challenges that come with using wooden pallets is the growth of mold. Pallet mold can wreak havoc on the products being transported, leading to losses for the manufacturers.Mold growth on pallets is caused by various factors like humidity, temperature, and moisture content. Once mold growth starts, it can spread quickly, leading to a complete infestation that may render the pallets unusable. Manufacturers need to take steps to prevent, inhibit and remediate pallet mold to reduce losses and ensure product safety.Preventing Pallet MoldPreventing mold growth on wooden pallets requires manufacturers to be proactive in their approach. Here are some ways to prevent pallet mold:1. Dry pallets thoroughly: Before using wooden pallets, ensure they are thoroughly dry. Moisture is a significant contributor to mold growth, and ensuring the pallets are dry can prevent mold growth.2. Proper storage: If pallets are not in use, they should be stored in a dry, well-ventilated area. If stored outside, cover the pallets with a tarp to prevent water from getting in.3. Use mold-resistant pallets: Some pallets come specifically treated with chemicals like borates to inhibit mold growth.Inhibiting Pallet MoldManufacturers may not always be able to prevent mold growth on pallets. However, inhibiting mold growth can help reduce losses. Here are some ways to inhibit pallet mold:1. Regular cleaning: Regularly cleaning the pallets can inhibit mold growth. Use a mild cleaning solution to wash the pallets, then air dry them in a well-ventilated area.2. Use anti-microbial coatings: Anti-microbial coatings can be applied to pallets to inhibit mold growth. These coatings can be applied using a spray method or a dipping method.3. Use pallet covers: Pallet covers can be used to protect the pallets from moisture and humidity, inhibiting mold growth.Remediating Pallet MoldIf mold growth is detected on wooden pallets, remediation is necessary to prevent it from spreading. Here are some ways to remediate pallet mold:1. Surface cleaning: Use a mild cleaning solution and a brush to clean the pallet surface thoroughly. Then, air dry the pallets.2. Secondary cleaning: If the mold growth is extensive, secondary cleaning may be necessary. Use a stronger solution and a pressure washer to clean the pallets.3. Fumigation: Fumigation may be necessary for severe cases of mold growth. This involves sealing the pallets in an airtight space and using chemicals to kill the mold.In conclusion, pallet mold is a significant concern for manufacturers, but steps can be taken to prevent, inhibit and remediate it. By being proactive, manufacturers can prevent mold growth on their pallets. If mold growth occurs, inhibiting its spread and remediating it can help reduce losses and ensure product safety. Manufacturers should ensure they have a pallet mold prevention plan in place.

Read More

30 Years of Experience in Environmentally Responsible Plastic Manufacturing

and Environmentally-Friendly Plastic Products.As consumers become increasingly aware of the impact of plastic on the environment, there is a growing demand for plastic products that are not only of the highest quality but are also environmentally friendly. This is where American plastic manufacturing companies like Polyfab Display come in – companies that are committed to producing high-quality plastic products while also being conscious of the environment.Polyfab Display is a plastic manufacturing company that has been in operation for over 30 years. Our company is dedicated to producing top-quality plastic products that meet the needs of our customers while also being kind to the environment. We understand that as a plastic manufacturer, we have a responsibility to minimize our environmental impact, and we take this responsibility very seriously.We have invested in the latest technology and manufacturing processes to ensure that our plastic products meet the highest industry standards for quality and environmental friendliness. We use energy-efficient equipment and processes to reduce our carbon footprint and minimize waste. We also recycle our plastic waste and encourage our customers to do the same, as part of our commitment to sustainability.At Polyfab Display, our focus is on creating durable, long-lasting plastic products that are designed to reduce waste and promote sustainability. Our products are made from a variety of environmentally-friendly materials, including recycled plastic, bioplastics, and low emission materials. These materials are carefully selected to ensure that they are free from harmful chemicals and do not have negative environmental impacts.Our plastic products are designed to be versatile and can be used in a variety of settings, including retail environments, trade shows, and events. We have a range of plastic products, including point of purchase displays, sign holders, and brochure holders, all of which can be customized to meet the unique needs of our customers.In addition to our commitment to the environment, we also prioritize customer satisfaction. We work closely with our customers to ensure that they receive the highest quality plastic products that meet their unique specifications. We pride ourselves on our exceptional customer service and are always happy to help our customers with their plastic product needs.In conclusion, American plastic manufacturing companies like Polyfab Display are leading the way in producing high-quality plastic products that are also environmentally friendly. Our company is committed to minimizing our environmental impact while also providing top-quality plastic products that meet the unique needs of our customers. We believe that it is possible to have both quality and sustainability, and we strive to achieve this balance in everything we do.

Read More

High-Capacity, Versatile Plastic Pallets: Ideal for Export and Pharmaceutical Industries

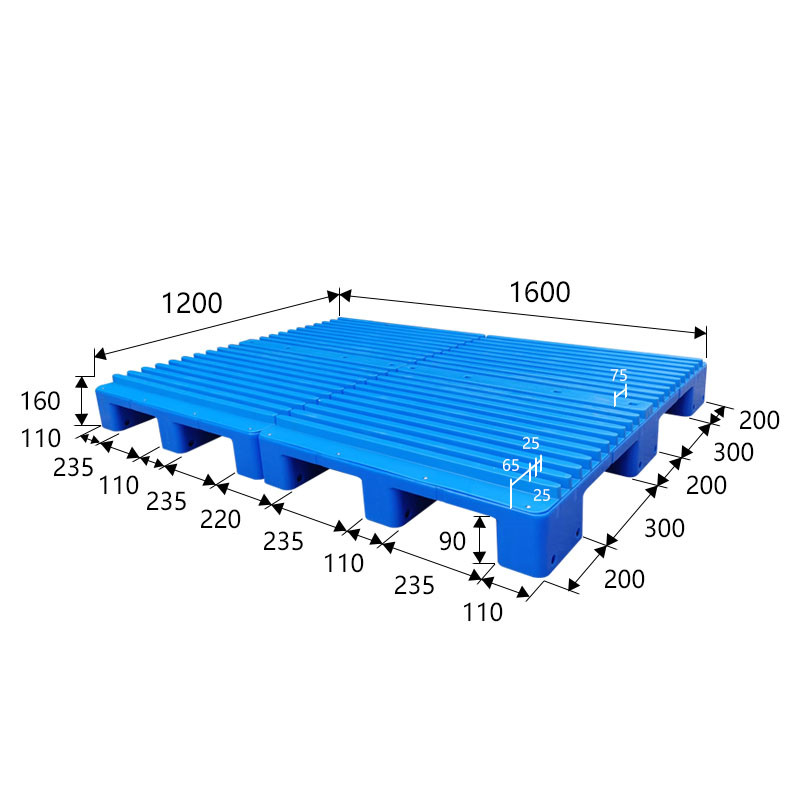

Title: Innovative Plastic Pallets: Revolutionizing Export Packaging SolutionsIntroduction:Plastic pallets have gained significant popularity in recent years, revolutionizing the export packaging industry due to their durability, cost-effectiveness, and eco-friendliness. This article will explore the load capacity, size, and unique applications of plastic pallets, especially focusing on euro plastic pallets and their contribution to transforming the export packaging sector.Company Introduction: [Insert Company Name][Company Name] is a leading manufacturer and supplier of high-quality plastic pallets. With a strong focus on innovation, we aim to provide sustainable, safe, and efficient packaging solutions for various industries. Our extensive range of plastic pallets ensures superior loading capacity, durability, and traceability, making them the ideal choice for export shipments.Load Capacity of Plastic Pallets:One of the key advantages of plastic pallets is their remarkable load capacity. Unlike their traditional wooden counterparts, plastic pallets are engineered to withstand heavy loads without warping, cracking, or breaking. With load capacities ranging from 1000kg to 2000kg, these versatile pallets are suitable for a wide range of applications, including the transportation of heavy machinery, automotive parts, pharmaceuticals, and more.Specialized Sizes for Different Industries:Plastic pallets come in various sizes to accommodate different industry requirements. Standard sizes include 1200x1000mm and 800x1200mm, which are widely used for general export purposes. Additionally, custom sizes can be manufactured to cater to specific industry needs, ensuring maximum efficiency and utilization of storage space during transportation.Export-Specific Euro Plastic Pallets:Euro plastic pallets have emerged as a popular choice for export shipments due to their standardized dimensions and compatibility with various transportation modes. These pallets adhere to the European Pallet Association (EPAL) standards, guaranteeing seamless integration within the global supply chain network. Euro plastic pallets typically measure 1200x800mm, making them an ideal choice for exporting goods to European countries.Advantages of Euro Plastic Pallets:Euro plastic pallets offer several unique advantages, making them the preferred choice for export-oriented businesses:1. Traceability: Euro plastic pallets are marked with identifiable logos and codes, ensuring easy tracking and traceability throughout the shipping process. This enables efficient inventory management and reduces the risk of lost or misplaced pallets.2. Hygiene and Compliance: Euro plastic pallets are easy to clean, reducing the risk of contamination during the transportation of pharmaceuticals and food products. They also comply with international regulations on sanitation, making them suitable for industries with strict hygiene requirements.3. Improved Ergonomics: These pallets are designed with ergonomic features such as anti-slip surfaces and reinforced corners, ensuring safe handling during loading and unloading processes. This reduces the risk of workplace injuries and enhances overall operational efficiency.Expanding Opportunities for Sustainable Export Packaging:Plastic pallets not only offer enhanced durability and load capacity but also contribute to environmental sustainability. Unlike wooden pallets, plastic pallets are reusable, recyclable, and do not require fumigation for international shipments. By opting for plastic pallets, businesses can reduce their carbon footprint and contribute to a greener future.Conclusion:Plastic pallets, with their exceptional load capacity, specialized sizes, and unique applications, have transformed the export packaging industry. Euro plastic pallets, in particular, have gained significant traction due to their adherence to global standards. As [Company Name] continues to innovate, our robust range of plastic pallets ensures safe and eco-friendly transportation of goods across various industries, revolutionizing the export packaging sector.

Read More

Affordable and Convenient Plastic Boxes for Easy Moving

Plastic Boxes For Moving: An Ideal Solution for Relocation NeedsRelocating to a new place can be an exciting adventure, but it often comes with the daunting task of packing and moving belongings. In the past, cardboard boxes were the go-to option for packing, but they often come with their fair share of drawbacks. Fragility, limited reusability, and vulnerability to moisture are just some of the issues faced by those who opt for cardboard boxes. However, with the introduction of Plastic Boxes For Moving, these challenges have become a thing of the past.Plastic Boxes For Moving, brought to you by a renowned industry leader, are revolutionizing the way people approach relocation. These sturdy, durable, and eco-friendly plastic boxes offer a superior alternative to traditional cardboard boxes. The company behind this innovative solution has been a prominent player in the packaging industry for years, ensuring only the highest quality products are provided to customers.Their plastic boxes are specifically designed to withstand the rigors of moving. Constructed from high-grade, impact-resistant plastic, these boxes are far less likely to break or tear compared to their cardboard counterparts. This added durability provides customers with peace of mind, knowing that their valuable belongings are well-protected during transit. Additionally, the boxes' capacity to stack securely minimizes the risk of items being damaged due to instability.Moreover, the reusability of Plastic Boxes For Moving makes them an environmentally friendly choice. Unlike cardboard boxes that are often discarded after just one use, these plastic boxes can be reused multiple times, significantly reducing waste. This not only benefits the environment but also proves to be more cost-effective for customers in the long run. Furthermore, the company's commitment to sustainability extends beyond their products, as they actively take part in various eco-friendly initiatives.The features of Plastic Boxes For Moving extend beyond durability and reusability. Their design includes integrated handles that make lifting and carrying the boxes a breeze. This ergonomic design prevents unnecessary strain or injuries that can occur when handling heavy items. Additionally, the boxes' interlocking lids provide a secure seal, ensuring the safety and security of the contents during transportation.To make the packing and moving process even more convenient, the company offers various sizes of plastic boxes to cater to different storage needs. Whether it's for bulky furniture, delicate glassware, or small trinkets, customers will find the perfect box to accommodate their belongings. The versatility and adaptability of these plastic boxes make them an ideal solution for not only residential moves but also commercial relocations.In addition to providing plastic boxes, the company offers a range of complementary services to further simplify the moving process. These include box delivery and pickup services, saving customers from the hassle of acquiring and disposing of boxes themselves. With the option to have the boxes delivered right to their doorstep, customers can focus on other aspects of their move, knowing that the logistics of packing are taken care of.As Plastic Boxes For Moving gain popularity, customers are praising the efficiency and effectiveness of this innovative solution. Many have recognized the substantial advantages over traditional cardboard boxes, with increased peace of mind, reduced environmental impact, and enhanced convenience being among the top benefits experienced.In conclusion, Plastic Boxes For Moving have transformed the way people approach relocation by offering a durable, reusable, and eco-friendly alternative to traditional cardboard boxes. With their commitment to quality and sustainability, accompanied by a range of complementary services, the company behind these plastic boxes has become a trusted name in the industry. Whether it's a residential or commercial move, these plastic boxes provide an ideal solution for all relocation needs.

Read More

High-Quality, Durable Plastic Pallet for Efficient Running Operations - The Ultimate Guide

In today’s world, where sustainability and eco-friendliness have become the buzzwords, companies are looking for ways to reduce their carbon footprint and make their processes more environmentally friendly. Many companies are turning to plastic pallets for their logistics needs as they are durable, hygienic, and can be reused multiple times. One such company producing plastic pallets is the 6 Runners Plastic Pallet - a leading manufacturer and supplier of high-quality plastic pallets.The 6 Runners Plastic Pallet, which was established in 1966 in Japan, has become a popular choice for companies looking for durable and long-lasting logistics solutions. They offer a comprehensive range of plastic pallets that are suitable for various industries, including food, beverage, pharmaceuticals, and retail.The plastic pallets produced by the 6 Runners Plastic Pallet is made of high-density polyethylene (HDPE), which makes them sturdy and strong. They are designed to carry heavy loads and are resistant to wear and tear, making them ideal for long-term use. This makes them an excellent investment for companies that need reliable logistics solutions.Apart from being durable, the plastic pallets produced by the 6 Runners Plastic Pallet are also lightweight. This means that they are easy to handle and transport. Additionally, they are also easy to clean and maintain, making them a more hygienic option compared to wood or metal.The 6 Runners Plastic Pallet is committed to sustainability and reducing environmental impact. Their plastic pallets are made from 100% recyclable materials, which means that they can be reused and repurposed multiple times. This reduces waste and conserves natural resources. The company also ensures that their production processes are environmentally responsible and comply with all regulations and standards.The benefits of using plastic pallets from the 6 Runners Plastic Pallet are many. They are resistant to moisture, mould, and bacteria, which makes them ideal for industries such as food and pharmaceuticals, where hygiene is critical. They are also stackable, which means that they take up less space, making them an excellent option for companies with limited storage space.In addition to their standard range of plastic pallets, the 6 Runners Plastic Pallet also offers custom solutions to meet the specific needs of their clients. This includes pallets in various sizes, shapes, and colours. They also offer printing and branding services, which means that companies can customize their pallets with logos and other branding elements.The 6 Runners Plastic Pallet has a robust distribution network, which ensures that their plastic pallets are readily available to clients. Their products are distributed worldwide, and they have a strong presence in Asia, Europe, and North America. With over 50 years of experience in the industry, the 6 Runners Plastic Pallet has built a reputation for quality, reliability, and customer service.In conclusion, the plastic pallets produced by the 6 Runners Plastic Pallet offer a sustainable and environmentally friendly logistics solution. They are durable, lightweight, and hygienic, making them an ideal option for various industries. With their focus on sustainability and compliance with regulations, the 6 Runners Plastic Pallet is a trusted partner for companies looking for a reliable logistics solution.

Read More

Plastic Press Pallets for Die Cutting and Printing Industries

Read More

Top Characteristics and Benefits of HDPE Plastic Pallets Revealed

Title: HDPE Plastic Pallets: A Sustainable and Versatile Solution in Modern Logistics Introduction (100 words):In today's fast-paced world, efficient and sustainable logistics solutions have become paramount for businesses seeking to streamline their operations. HDPE Plastic Pallets (brand withheld) offer a versatile, durable, and eco-friendly alternative to traditional wooden pallets. These pallets, made from high-density polyethylene (HDPE), possess several advantages such as increased longevity, resistance to moisture and chemicals, and ease of recycling. With their wide-ranging applications in various industries, HDPE Plastic Pallets are revolutionizing logistics practices globally, optimizing supply chain management, and reducing environmental footprint.Body:1. Exploring the Features and Benefits of HDPE Plastic Pallets (200 words):HDPE Plastic Pallets are designed to provide utmost reliability and durability in industrial settings. With their exceptional resistance to impact, moisture, and chemicals, these pallets are capable of withstanding demanding conditions, offering a longer lifespan compared to traditional wooden pallets. Moreover, HDPE Plastic Pallets are easier to clean and maintain, ensuring hygienic transportation of goods, particularly in industries such as food and pharmaceuticals. This feature significantly reduces the risk of cross-contamination and product damage, guaranteeing the integrity of the supply chain.The versatility of HDPE Plastic Pallets is another key feature that sets them apart. Their ability to be customized for various storage and transportation needs, including different sizes, shapes, and load capacities, make these pallets suitable for a wide range of applications across industries. From heavy machinery to delicate electronics, these pallets can securely and efficiently handle diverse products.Furthermore, the lightweight nature of HDPE Plastic Pallets offers businesses significant cost-saving advantages. Reduced weight means lower transportation costs, enhanced fuel efficiency, and minimal strain on workers when handling or manipulating the pallets. Additionally, HDPE Plastic Pallets do not harbor pests, fungi, or mold, decreasing the risk of product contamination and improving overall safety standards.2. Environmentally Friendly and Sustainable Solution (200 words):One of the most prominent benefits of HDPE Plastic Pallets is their positive impact on the environment. Unlike wooden pallets, which require frequent replacement due to degradation, HDPE Plastic Pallets have a longer lifespan and can be recycled into new pallets at the end of their useful life. This recycling process reduces waste generation while conserving resources.By adopting HDPE Plastic Pallets, companies can contribute significantly to reducing deforestation, as no trees are felled in the production of these pallets. This proactive step aligns with the growing global emphasis on sustainability and responsible sourcing.In addition to sustainability, HDPE Plastic Pallets also address safety concerns often associated with wooden pallets. Wooden pallets may have exposed nails or splinters, posing risks to workers and products. In contrast, HDPE Plastic Pallets are designed to be smooth, sturdy, and free of any protruding hazards, creating a safer work environment.3. Industry Applications and Global Adoption (200 words):HDPE Plastic Pallets have gained significant traction across a wide range of industries and countries. In the automotive sector, these pallets have proven to be an invaluable solution due to their load-bearing capacity, chemical resistance, and ability to withstand extreme temperatures. Similarly, in the food industry, the hygienic nature of HDPE Plastic Pallets makes them indispensable for the transportation of perishable goods and compliance with strict quality and safety standards.The pharmaceutical industry also greatly benefits from HDPE Plastic Pallets due to their inert nature, ensuring the integrity and safety of pharmaceutical products during transportation and storage. Other industries, such as retail, logistics, and agriculture, are also increasingly embracing HDPE Plastic Pallets for their durability, versatility, and sustainability credentials.In conclusion, HDPE Plastic Pallets are revolutionizing modern logistics practices by offering a sustainable, versatile, and durable alternative to traditional wooden pallets. These pallets enhance supply chain efficiency, reduce environmental footprint, and improve overall safety standards. With their wide-ranging applications across various industries, HDPE Plastic Pallets have become an essential component of modern-day logistics, ensuring seamless transportation of goods while minimizing the impact on the planet.

Read More

Two Chinese Solar Manufacturing Companies Sign High-Purity Polysilicon Supply Agreements

High-Purity Polysilicon Supply Agreements: Signaling the Growing Demand for Solar Energy in ChinaThe global demand for clean and renewable energy has been increasing rapidly in recent years, and solar power is one of the most promising sources of renewable energy. China, known as the world's largest solar panel manufacturer and consumer, has made remarkable strides in promoting and expanding its solar power industry. This trend is evidenced by the announcement of two high-purity polysilicon supply agreements by Daqo New Energy Corp.'s subsidiaries, one with LONGi and another solar manufacturing company in China.Polysilicon is a key component in the manufacturing of solar panels, and high-purity polysilicon is necessary for the production of high-efficiency solar cells. Daqo New Energy Corp. is a leading producer of high-purity polysilicon, and its subsidiaries' agreements with LONGi and another solar manufacturing company in China signify the growing demand for solar energy in China.LONGi is the world's largest solar wafer manufacturer, and its partnership with Daqo New Energy Corp. is expected to strengthen its supply chain and meet the increasing demand for solar products. "We are pleased to strengthen our strategic partnership with Daqo New Energy Corp. Our companies share a commitment to sustainable development and providing cost-effective solar solutions to customers worldwide," said Li Zhenguo, President of LONGi.The second agreement with another solar manufacturing company in China shows the broader demand for high-purity polysilicon as solar power continues to expand in the country. With China's pledge to achieve carbon neutrality by 2060, the demand for clean energy will continue to grow, and high-purity polysilicon will be needed to support this growth.Daqo New Energy Corp.'s supply agreements demonstrate its market leadership in the production of high-purity polysilicon and its commitment to meeting the demand for solar energy in China, the world's largest solar market. The company's high-quality products and superior technology allow it to meet the needs of customers while contributing to a sustainable future.The growing demand for solar energy in China presents a significant opportunity for companies in the solar power industry. Manufacturers of high-purity polysilicon like Daqo New Energy Corp. are poised to benefit from this trend by meeting the increasing demand for solar panels. As the world transitions to clean and renewable energy, the demand for high-purity polysilicon will continue to grow, making it a valuable commodity in the solar power industry.In conclusion, the announcement of two high-purity polysilicon supply agreements by Daqo New Energy Corp.'s subsidiaries with LONGi and another solar manufacturing company in China highlights the growing demand for solar energy in China. As the country moves towards carbon neutrality, the demand for clean and renewable energy will continue to rise, creating significant opportunities for companies in the solar power industry. Manufacturers of high-purity polysilicon will play a critical role in meeting this demand, making it a promising commodity for investors in the renewable energy sector.

Read More