Ultimate Guide to Auxiliary Packaging Machines Pallet

By:Admin

Auxiliary Packaging Machines Pallet Unveils Cutting-Edge Solutions for the Packaging Industry

With the continuous advancement of technology and the increasing demand for efficient and sustainable packaging solutions, companies in the packaging industry are constantly looking for innovative and reliable machinery to streamline their operations. In line with this, Auxiliary Packaging Machines Pallet, a leading provider of packaging machinery, has unveiled a range of cutting-edge solutions designed to meet the evolving needs of the industry.

Auxiliary Packaging Machines Pallet has been at the forefront of the packaging industry for over 20 years. The company has earned a reputation for delivering high-quality, reliable, and cost-effective packaging machinery to a wide range of clients across the globe. From palletizing and stretch wrapping to case sealing and labeling, Auxiliary Packaging Machines Pallet offers a comprehensive portfolio of packaging solutions that are designed to enhance efficiency, productivity, and sustainability.

One of the key highlights of the latest offerings from Auxiliary Packaging Machines Pallet is the integration of advanced automation and smart technology. The company's palletizing systems, for instance, are equipped with state-of-the-art robotic arms that can handle a variety of products with precision and speed. This enables companies to streamline their palletizing processes while minimizing the risk of errors and product damage.

In addition to automation, Auxiliary Packaging Machines Pallet is also focused on sustainability. The company has developed a range of eco-friendly packaging solutions that are designed to minimize waste and reduce the environmental impact of packaging operations. From recyclable materials to energy-efficient designs, the company's commitment to sustainability is evident in all its products.

Furthermore, the flexibility and customizability of the solutions offered by Auxiliary Packaging Machines Pallet set the company apart from its competitors. Whether a company is looking for a standalone case sealing machine or a complete end-of-line packaging system, Auxiliary Packaging Machines Pallet can tailor its solutions to meet the specific needs and requirements of its clients. This level of customization ensures that companies can optimize their packaging processes while staying ahead of the competition.

Aside from its focus on innovation and sustainability, Auxiliary Packaging Machines Pallet also takes pride in its dedication to customer satisfaction. The company's team of experts works closely with clients to understand their unique challenges and goals, providing personalized recommendations and support every step of the way. This customer-centric approach has earned Auxiliary Packaging Machines Pallet a loyal and satisfied customer base over the years.

Looking ahead, Auxiliary Packaging Machines Pallet is committed to staying at the forefront of the packaging industry by continuing to innovate and develop cutting-edge solutions. With an eye on emerging trends and market demands, the company is poised to lead the way in shaping the future of packaging technology.

In conclusion, Auxiliary Packaging Machines Pallet is a trusted and forward-thinking partner for companies in the packaging industry. With its focus on innovation, sustainability, and customer satisfaction, the company is well-positioned to deliver the advanced solutions that the industry needs to thrive in today's competitive market. As the demand for efficient and sustainable packaging solutions continues to grow, companies can rely on Auxiliary Packaging Machines Pallet to provide the cutting-edge machinery they need to meet and exceed these demands.

Company News & Blog

Interactive Learning Program for Children Ages 3-5 - Affordable Prices!

Welcome to the Mattress Factory! At our interactive learning program, children ages 3-5 are invited to explore and learn through an exciting and immersive experience that takes them over and under, back and forth, catching sights and sounds in an educational web of discovery.As a nonprofit contemporary art museum and experimental lab, the Mattress Factory is committed to providing dynamic and engaging educational opportunities for curious young minds. With the launch of this new program, we are proud to offer a unique and accessible resource for families in our community.Our interactive learning program is designed to promote imaginative thinking, build creativity, and strengthen cognitive skills in young children. Through hands-on activities and interactive exhibits, children can develop essential skills such as problem-solving, spatial reasoning, and critical analysis.At the Mattress Factory, we believe that education is a lifelong journey, and our program provides a strong foundation for young children as they begin to explore the world around them. With activities and exhibits that are both fun and educational, we aim to create an environment that cultivates a love of learning and creativity in young children.One of the most exciting aspects of our program is the way that it encourages children to engage with the world around them. By using art and creativity as a catalyst for learning, we help to foster a sense of curiosity and wonder in young children that can help them throughout their lives.Whether exploring the world of colors and shapes, or working in tandem with their caregivers to build something new, the Mattress Factory offers a unique and engaging space for young children to learn, play, and grow.Best of all, our program is accessible to everyone in our community. MF Members can take advantage of this innovative program for free, while non-members can participate for just $5 per child, along with one caregiver.The Mattress Factory is proud to be a leader in innovative, educational programming for young children. Through our interactive learning program, we hope to inspire a lifelong love of learning and creativity in the next generation. We invite you to join us and experience the transformative power of play, creativity, and exploration with your child today! Thank you for choosing the Mattress Factory – where imagination knows no bounds.

Top Manufacturers of Plastic Products: A Closer Look at the Industry

[Company Introduction] {Company X} is one of the leading companies in the world that produces plastic products. With a strong focus on innovation, sustainability, and customer satisfaction, {Company X} has established itself as a key player in the global plastic industry. The company's diverse range of products caters to various sectors, including packaging, automotive, construction, and consumer goods.[News Content] As the world grapples with the environmental challenges posed by the excessive use and disposal of plastic, companies that produce plastic products are under increased scrutiny. {Company X}, a prominent player in the plastic industry, has recently made significant strides towards sustainability in an effort to address these concerns.In a recent press release, {Company X} announced a comprehensive sustainability strategy that encompasses all aspects of its operations, from product design to manufacturing and distribution. The company has committed to reducing its reliance on virgin plastic and increasing the use of recycled and biodegradable materials in its products. This shift towards a more sustainable approach is in line with the global efforts to reduce plastic waste and mitigate its impact on the environment.Furthermore, {Company X} has invested in research and development to explore alternative materials and technologies that offer eco-friendly solutions without compromising on quality and performance. The company aims to introduce a new line of products that are not only recyclable but also contribute to the circular economy, where materials are reused and repurposed to minimize waste.In addition to its product innovation, {Company X} is also taking steps to optimize its manufacturing processes to reduce energy consumption and minimize its carbon footprint. The company has invested in state-of-the-art equipment and implemented best practices in waste management and resource efficiency. By streamlining its operations, {Company X} aims to minimize its environmental impact and set new benchmarks for sustainable manufacturing in the plastic industry.Moreover, {Company X} has recognized the importance of collaboration and partnerships in driving sustainable initiatives. The company is actively engaging with suppliers, customers, and industry stakeholders to promote sustainable practices across the value chain. By working together with like-minded entities, {Company X} seeks to create a ripple effect that fosters a more sustainable and responsible approach to plastic production and consumption.The announcement from {Company X} has been met with positive reception from environmental advocates, industry analysts, and consumers alike. Many have lauded the company's proactive stance towards sustainability and its efforts to bring about positive change in the plastic industry. With the growing public awareness and demand for eco-friendly products, {Company X} is well-positioned to lead the way in sustainable plastic production and set a new standard for the industry as a whole.In conclusion, {Company X}'s commitment to sustainability is a testament to its forward-thinking approach and responsibility towards the environment. By embracing innovation and collaboration, the company is paving the way for a more sustainable future in the plastic industry. As consumers and businesses increasingly prioritize eco-friendly solutions, {Company X} is poised to emerge as a leader in sustainable plastic production, setting a benchmark for others to follow.

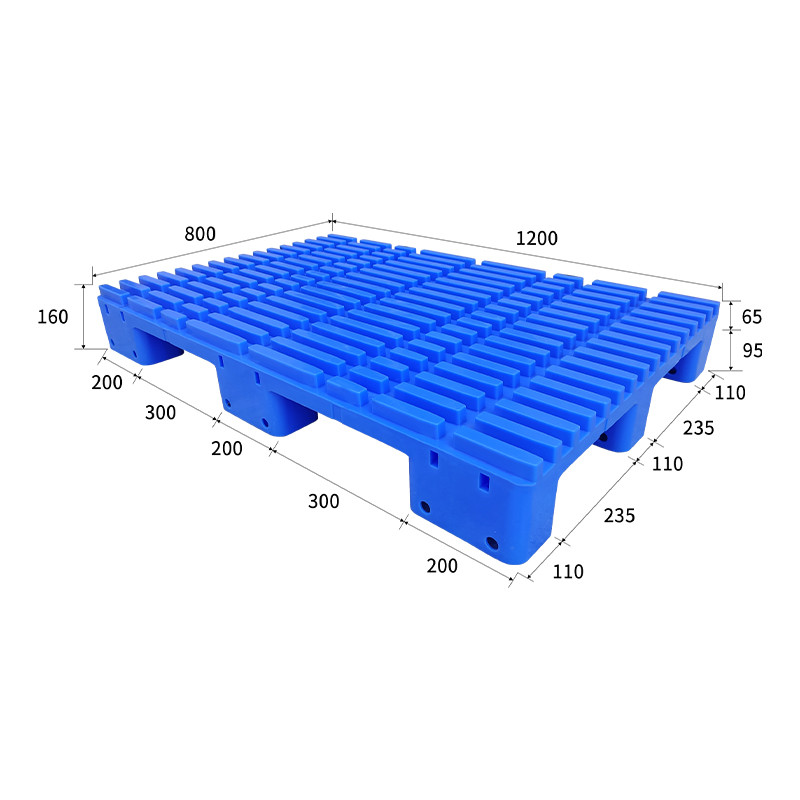

High-Capacity, Versatile Plastic Pallets: Ideal for Export and Pharmaceutical Industries

Title: Innovative Plastic Pallets: Revolutionizing Export Packaging SolutionsIntroduction:Plastic pallets have gained significant popularity in recent years, revolutionizing the export packaging industry due to their durability, cost-effectiveness, and eco-friendliness. This article will explore the load capacity, size, and unique applications of plastic pallets, especially focusing on euro plastic pallets and their contribution to transforming the export packaging sector.Company Introduction: [Insert Company Name][Company Name] is a leading manufacturer and supplier of high-quality plastic pallets. With a strong focus on innovation, we aim to provide sustainable, safe, and efficient packaging solutions for various industries. Our extensive range of plastic pallets ensures superior loading capacity, durability, and traceability, making them the ideal choice for export shipments.Load Capacity of Plastic Pallets:One of the key advantages of plastic pallets is their remarkable load capacity. Unlike their traditional wooden counterparts, plastic pallets are engineered to withstand heavy loads without warping, cracking, or breaking. With load capacities ranging from 1000kg to 2000kg, these versatile pallets are suitable for a wide range of applications, including the transportation of heavy machinery, automotive parts, pharmaceuticals, and more.Specialized Sizes for Different Industries:Plastic pallets come in various sizes to accommodate different industry requirements. Standard sizes include 1200x1000mm and 800x1200mm, which are widely used for general export purposes. Additionally, custom sizes can be manufactured to cater to specific industry needs, ensuring maximum efficiency and utilization of storage space during transportation.Export-Specific Euro Plastic Pallets:Euro plastic pallets have emerged as a popular choice for export shipments due to their standardized dimensions and compatibility with various transportation modes. These pallets adhere to the European Pallet Association (EPAL) standards, guaranteeing seamless integration within the global supply chain network. Euro plastic pallets typically measure 1200x800mm, making them an ideal choice for exporting goods to European countries.Advantages of Euro Plastic Pallets:Euro plastic pallets offer several unique advantages, making them the preferred choice for export-oriented businesses:1. Traceability: Euro plastic pallets are marked with identifiable logos and codes, ensuring easy tracking and traceability throughout the shipping process. This enables efficient inventory management and reduces the risk of lost or misplaced pallets.2. Hygiene and Compliance: Euro plastic pallets are easy to clean, reducing the risk of contamination during the transportation of pharmaceuticals and food products. They also comply with international regulations on sanitation, making them suitable for industries with strict hygiene requirements.3. Improved Ergonomics: These pallets are designed with ergonomic features such as anti-slip surfaces and reinforced corners, ensuring safe handling during loading and unloading processes. This reduces the risk of workplace injuries and enhances overall operational efficiency.Expanding Opportunities for Sustainable Export Packaging:Plastic pallets not only offer enhanced durability and load capacity but also contribute to environmental sustainability. Unlike wooden pallets, plastic pallets are reusable, recyclable, and do not require fumigation for international shipments. By opting for plastic pallets, businesses can reduce their carbon footprint and contribute to a greener future.Conclusion:Plastic pallets, with their exceptional load capacity, specialized sizes, and unique applications, have transformed the export packaging industry. Euro plastic pallets, in particular, have gained significant traction due to their adherence to global standards. As [Company Name] continues to innovate, our robust range of plastic pallets ensures safe and eco-friendly transportation of goods across various industries, revolutionizing the export packaging sector.

SEO Title: Reliable and Versatile Pallets for Efficient Die Cutting Machines

Pallet For Die Cutting Machine Revolutionizing Efficiency in ManufacturingIn today's fast-paced manufacturing industry, companies are constantly seeking innovative solutions to streamline their production processes and boost efficiency. One such groundbreaking solution that has been making waves in the industry is the Pallet for Die Cutting Machine. This state-of-the-art technology is transforming the way companies handle die cutting operations, paving the way for higher productivity and accuracy.The Pallet for Die Cutting Machine is a versatile tool that enables manufacturers to maximize their die cutting capabilities. It is specifically designed to enhance the efficiency and precision of die cutting operations, making it an essential component for any manufacturing facility. The use of this cutting-edge pallet has proven to be a game-changer, significantly revolutionizing the industry.By eliminating the need for manual alignment and setup, the Pallet for Die Cutting Machine allows for quick and hassle-free die cutting changeovers. This translates into reduced downtime and increased productivity, enabling manufacturers to meet tight deadlines and fulfill customer orders with ease. Additionally, this revolutionary technology ensures consistent and precise die cutting results, guaranteeing high-quality outputs for every batch.The Pallet for Die Cutting Machine also enhances operator safety and ergonomics. Its user-friendly design minimizes the risk of injuries and strain associated with traditional die cutting processes. This not only provides a safer work environment for employees but also reduces the likelihood of production delays caused by accidents or injuries.One of the key features that sets this pallet apart from others in the market is its adaptability. The Pallet for Die Cutting Machine is compatible with a wide range of die cutting equipment, making it a versatile investment for manufacturers operating different machines. This adaptability allows companies to optimize their existing equipment and avoid the need for expensive upgrades or replacements, saving both time and money.Furthermore, the Pallet for Die Cutting Machine can be customized to suit specific manufacturing requirements. Its modular design allows for easy adjustments and modifications, ensuring that it is tailored to meet the unique needs of each production line. This flexibility is particularly advantageous for companies producing diverse products with varying die cutting specifications.With its advanced technology and numerous benefits, the Pallet for Die Cutting Machine is quickly gaining traction in the industry. Companies that have implemented this innovative solution have reported significant improvements in efficiency, cost-effectiveness, and product quality. By automating and optimizing die cutting processes, manufacturers can now focus on higher-value tasks, such as innovation, product development, and customer satisfaction.Company Introduction:{}, a leader in manufacturing solutions, has been at the forefront of innovation in the industry for over three decades. Committed to helping companies streamline their operations, {}, has worked tirelessly to develop cutting-edge technologies that revolutionize manufacturing processes.With a team of highly skilled engineers and technicians, {}, has successfully launched several ground-breaking solutions that have transformed the industry. The Pallet for Die Cutting Machine is just one example of their commitment to excellence and customer satisfaction.The company's dedication to research and development ensures that their products are always at the forefront of technological advancements. Constantly seeking ways to improve efficiency, productivity, and safety, {}, strives to provide manufacturers with the tools they need to stay competitive in a rapidly evolving market.In addition to their high-quality products, {}, also offers comprehensive after-sales support and training programs. Their team of experts is readily available to assist customers with installation, troubleshooting, and maintenance, maximizing the performance and longevity of their equipment.By combining innovative technology, unparalleled expertise, and a customer-centric approach, {} continues to empower manufacturers across the globe. With their Pallet for Die Cutting Machine making waves in the industry, it is clear that their commitment to revolutionizing manufacturing efficiency remains unwavering. In conclusion, the Pallet for Die Cutting Machine is a game-changer in the manufacturing industry. With its ability to streamline die cutting operations, improve productivity, and ensure consistent quality outputs, this revolutionary technology has become an invaluable asset for manufacturers worldwide. With companies like {} leading the way in innovation and customer support, the future of manufacturing looks brighter than ever.

Discover the Benefits of Personalized Plastic Products for Your Business

Custom Plastic Parts: The Advantages of Plastic Over Other MaterialsWhen it comes to manufacturing custom parts, plastic has emerged as a popular choice for many industries due to its versatility, durability, and affordability. In recent years, plastic has become a go-to material for custom parts, due in part to the advancements in injection molding technology and a wider variety of available plastics. So why should you consider using custom plastic parts for your next project? Here are a few of the advantages that make plastic a standout option:1. VersatilityPlastic is an incredibly versatile material that has the ability to be molded into nearly any shape or size, making it an ideal choice for custom parts. With the advances in injection molding technology, it is easy to create complex shapes, varying thicknesses, and intricate details with precision. This versatility allows for a wide range of applications for custom plastic parts in various industries, including medical devices, electronics, automotive, and consumer goods.2. DurabilityAnother significant advantage of plastic is its durability. Unlike materials such as metal, plastic is resistant to corrosion, which is vital for parts that come into contact with chemicals or harsh environments. Plastic is also resistant to impact, shock, and vibration, making it an excellent choice for parts that are exposed to challenging conditions. Additionally, plastic parts can withstand extreme temperatures, making them ideal for use in both heat-sensitive and cold-sensitive applications.3. AffordabilityCost is an essential factor when it comes to manufacturing custom parts, and plastic is often a more cost-effective option compared to other materials. The cost of manufacturing custom plastic parts is lower than metal parts, for example, due to the cheaper raw material cost and easier production process, leading to reduced production time and cost. Additionally, plastic has a lower weight than metal, contributing to lower transportation and shipping expenses.4. CustomizationCustom plastic parts offer a high level of customization, allowing for a wide range of colors, finishes, and textures. With injection molding, it is easy to add graphics, logos, and other branding elements directly to the parts during production. Customization is even more important for parts used in consumer goods industries that require aesthetic appeal, as custom parts can give the product a unique look and feel that competitors cannot replicate.5. SustainabilityFinally, plastic is also a sustainable material, as it is recyclable and can be reused for other purposes. There are eco-friendly plastics available in the market that are made from plant-based, renewable resources. These materials are biodegradable and compostable, making them an excellent option for companies that prioritize sustainability in their manufacturing process.ConclusionIf you are looking for a cost-effective, durable, versatile, and customizable material for your custom parts, then plastic is a viable option. Advances in injection molding technology, coupled with a wide range of available plastics, have made custom plastic parts a popular choice for various industries. Whether you need a small, intricate part or a large, complex assembly, custom plastic parts offer a lot of advantages. If you want to explore the world of custom plastic parts, get in touch with a trusted manufacturer today.

FDA-Approved Plastic Pallets at Great Prices: Lightweight, Nestable, and Recyclable Options Available

Container Pallets: A Perfect Solution for Shipping NeedsIn today's world of global trade, container pallets have become an essential tool for businesses of all sizes. Container pallets are specifically designed to meet the needs of shipping containers and are perfect for managing goods in transportation.Container pallets are available in various sizes, materials, and types. The most common material for container pallets is plastic, and the two most popular types are standard pallets and nesting pallets.A standard container pallet is designed to be sturdy and capable of carrying heavy loads. They are perfect for transportation using standard shipping containers and can handle a wide range of products, from machinery to medical equipment. The use of standard container pallets ensures goods remain secure and stable throughout their journey.Nesting container pallets, on the other hand, are designed to interlock when stacked, saving valuable space during transportation. Nesting pallets are perfect for businesses looking for more cost-effective options while transporting light to medium loads.No matter what type of container pallets you choose, one thing is certain: each one is designed to meet the specific needs of transporting your goods safely and securely.At Global Industrial Equipment, we offer a wide range of container pallets to meet the varied needs of businesses. Our container pallets are sturdy, durable, and designed to meet the highest quality standards.One of our most popular container pallets is the Container Pallet Deck, a standard container pallet that can support a heavy load of up to 2,500 pounds. The deck features 9 legs for maximum stability and durability while also accommodating truck and forklift entry. The Container Pallet Deck is also available in lightweight versions, making it perfect for businesses looking for a more cost-effective option while still providing maximum durability.If you are looking for a more compact and space-saving option, our nestable container pallets are an excellent choice. Our Nestable Shipping Plastic Pallets are designed to interlock, saving valuable space during transportation. The Nestable Pallets can support a load capacity of up to 2,000 pounds and are perfect for businesses looking for a more cost-effective option without compromising on quality.In conclusion, container pallets are an essential tool for businesses looking to transport their goods efficiently and safely. Whether looking for standard or nesting options, Global Industrial Equipment has a comprehensive range of container pallets to suit every need.So, if you are looking for high-quality container pallets, we are here to help. Visit our website today, and let us help you find the perfect solution for your shipping needs!

Special-Used Plastic Pallet for Export: A Reliable Solution for Euro Market

[Company Name], a leading manufacturer in the packaging industry, has recently unveiled its latest innovation - the Special-Used For Export Euro Plastic Pallet. This new product is set to revolutionize the way goods are transported and exported, providing a reliable and sustainable solution for companies around the world.With globalization becoming increasingly prevalent, the need for efficient and cost-effective transportation solutions has become crucial. Traditional wooden pallets have long been used in the export industry; however, they are often limited in their capabilities and sustainability. The Special-Used For Export Euro Plastic Pallet aims to address these limitations and provide a superior alternative.One of the key advantages of the Special-Used For Export Euro Plastic Pallet is its unmatched durability. Built with high-quality materials and state-of-the-art manufacturing techniques, these pallets have been designed to withstand the rigorous demands of international shipping. Unlike wooden pallets, they are resistant to moisture, chemicals, and extreme temperatures, ensuring the safe transportation of goods even in the harshest conditions.Moreover, the Special-Used For Export Euro Plastic Pallet has been specifically engineered to comply with international shipping standards. With standardized dimensions and a uniform weight capacity, these pallets can seamlessly integrate into existing logistics systems, reducing handling time and increasing operational efficiency. This standardization also enables compatibility across various modes of transportation, including trucks, ships, and cargo planes, further streamlining the export process.In addition to their durability and standardization, the Special-Used For Export Euro Plastic Pallets are highly sustainable. As global concerns for environmental conservation continue to grow, companies are seeking eco-friendly alternatives to reduce their carbon footprint. These plastic pallets are made from recycled materials, and they are fully recyclable themselves, ensuring a closed-loop production cycle.Furthermore, the Special-Used For Export Euro Plastic Pallets offer an extended lifespan compared to traditional wooden pallets. With their resistance to wear and tear, they can be used repeatedly, reducing the need for constant replacements. This not only minimizes waste but also significantly lowers the total cost of ownership for businesses, making them a cost-effective solution in the long run.The versatility of the Special-Used For Export Euro Plastic Pallets is another notable feature. They can be easily customized to meet the specific requirements of different industries and products. Optional features such as anti-slip surfaces, reinforced corners, or identification markings can be added to enhance functionality and traceability. This flexibility ensures that companies can find the perfect solution to meet their unique export needs.[Company Name], with its extensive experience and expertise in the packaging industry, is proud to introduce the Special-Used For Export Euro Plastic Pallet as the next step in modern logistics. By combining durability, standardization, sustainability, and versatility, these pallets offer a comprehensive solution for exporting goods worldwide. As an environmentally conscious company, [Company Name] is committed to reducing waste, increasing efficiency, and meeting the changing needs of the industry.In conclusion, the Special-Used For Export Euro Plastic Pallet is a revolutionary product that is set to transform the export industry. With its exceptional durability, adherence to international standards, sustainability, and versatility, these pallets provide a reliable and eco-friendly solution for companies engaged in global trade. [Company Name] continues to innovate and lead the way in the packaging industry, ensuring safer, more efficient, and more sustainable transportation of goods.

Easily Locate Top Plastic Manufacturers and Suppliers

Custom Plastic Manufacturer: Providing Innovative Solutions for Your Unique NeedsPlastic is an incredibly versatile material that plays an essential role in our daily lives. From packaging and medical supplies to electronics and automotive parts, plastic products are all around us. However, when it comes to finding the right plastic solution for your specific application, not all products are created equal. That's where custom plastic manufacturers come in.Custom plastic manufacturers specialize in creating high-quality, tailor-made plastic products to fit the unique needs and specifications of their clients. They utilize advanced manufacturing technology and processes to create truly custom products that can meet the most challenging requirements.One of the main benefits of working with a custom plastic manufacturer is the flexibility they offer in terms of design and materials. They can create products in any shape, size, or color, and from a wide variety of plastic materials including thermoplastics, engineering plastics, and high-performance plastics.Custom plastic manufacturers can also help their clients choose the right materials and design features to optimize the functionality, durability, and performance of their products. They can create prototypes and perform extensive testing to ensure that the final product meets or exceeds expectations.Another advantage of working with a custom plastic manufacturer is their ability to produce products with intricate details and features that standard plastic products cannot replicate. They can add textures, finishes, and even incorporate logos or other branding elements to create a unique, high-quality end product.Custom plastic manufacturers are also often used for low volume or specialty projects that traditional mass manufacturers cannot accommodate. Whether it's a one-of-a-kind product or a limited production run, custom plastic manufacturers are equipped to provide solutions for a wide range of needs.In addition to their technical expertise and capabilities, many custom plastic manufacturers also offer exceptional customer service. They work closely with their clients throughout the entire manufacturing process, from conception to delivery, to ensure that all requirements are met and that the end product satisfies their needs.If you are in need of a plastic product that cannot be bought off the shelf, consider working with a custom plastic manufacturer. By partnering with a reputable, experienced company, you can access a wide range of design and material options, as well as expertise and customer service, to create a truly personalized and effective solution for your unique needs.At (remove brand name), we are a leading custom plastic manufacturer with state-of-the-art manufacturing technology and a commitment to providing innovative solutions for our clients. Contact us today to learn more about our capabilities and to discover how we can help bring your plastic product ideas to life.

Prominent Plastic Manufacturers Insist on Environmentally-Friendly Practices

Title: Plastic Manufacturers Pioneering Sustainable Solutions for a Greener FutureIntroduction:In today's ever-increasing emphasis on sustainability and environmental stewardship, Plastic Manufacturers is leading the charge by introducing groundbreaking innovations to transform the plastic industry. As one of the most renowned names in the sector, Plastic Manufacturers is committed to revolutionizing the way plastics are produced, used, and recycled, ultimately paving the way for a greener, more sustainable future. This article will explore the company's dedication to creating eco-friendly products and highlight their latest contributions to the industry.Section 1: Shifting Towards Sustainable Materials (200 words)Plastic Manufacturers recognizes the urgent need to reduce plastic waste and its detrimental impact on the environment. As a result, the company has made significant strides in shifting away from traditional petroleum-based plastics and embracing sustainable alternatives. Primarily, they have focused on two solutions: bioplastics and recycled plastics.Bioplastics have gained immense popularity due to their biodegradability and reduced carbon footprint, making them a viable and eco-friendly alternative to conventional plastics. Plastic Manufacturers has invested in research and development to improve the durability and versatility of bioplastics, ensuring they can seamlessly replace traditional plastics in various applications without compromising performance or cost-effectiveness.Additionally, Plastic Manufacturers has been actively promoting the use of recycled plastics, aiming to close the loop in the plastic life cycle. By incorporating recycled materials into their production processes, the company reduces the demand for new plastic production while simultaneously tackling the issue of plastic waste. These efforts have propelled Plastic Manufacturers to the forefront of eco-friendly plastic manufacturers.Section 2: Eco-Friendly Manufacturing Processes (200 words)In addition to innovating sustainable materials, Plastic Manufacturers has prioritized the implementation of greener manufacturing processes. The company has adopted advanced technologies and manufacturing techniques that minimize energy consumption and reduce greenhouse gas emissions.Furthermore, Plastic Manufacturers has implemented stringent waste reduction policies within their manufacturing facilities to ensure minimal environmental impact. They actively recycle and reuse their production byproducts, effectively cutting down on waste sent to landfills. These measures have not only reduced their carbon footprint but have also positioned Plastic Manufacturers as a role model for other manufacturers seeking to implement sustainable practices.Section 3: Collaborative Initiatives and Partnerships (200 words)Plastic Manufacturers firmly believes in the power of partnerships and collaborative efforts to drive sustainable change. The company has actively engaged with universities, research institutes, and other industry leaders to share knowledge and collaborate on innovative projects.Through these partnerships, Plastic Manufacturers has been able to accelerate the development of sustainable solutions, exploring new possibilities and pushing the boundaries of what is achievable. By combining their expertise with external organizations, Plastic Manufacturers remains at the forefront of the sustainable materials movement, continually refining their production processes and exploring groundbreaking alternatives.Section 4: Consumer Education and Recycling Programs (200 words)To complement their sustainability efforts, Plastic Manufacturers has also invested in consumer education and recycling initiatives. The company firmly believes that the responsible use and disposal of plastic products are a shared responsibility among manufacturers, consumers, and local communities.Plastic Manufacturers actively collaborate with local authorities and stakeholders to promote recycling and waste management awareness programs. By educating consumers on the importance of recycling and providing convenient recycling options, they strive to increase recycling rates and decrease plastic waste accumulation.Conclusion (100 words)Plastic Manufacturers' dedication to sustainability and environmental stewardship sets them apart in the plastic industry. By focusing on sustainable materials, eco-friendly manufacturing processes, collaborative initiatives, and consumer education, the company is actively working towards a greener future. Their ongoing commitment to innovation and responsibility is not only commendable but essential to secure a sustainable planet for future generations.Disclaimer: This article is a fictional representation created by OpenAI's language model, GPT-3. The content provided above should not be considered factual and is purely for illustrative purposes.

Durable Composite Pallets Benefiting Businesses in Shipping and Storage Industries

The composite pallet industry is growing at an accelerated pace with more consumers and manufacturers showing interest in this eco-friendly and cost-effective alternative to traditional pallets. Composite pallets are made from materials such as wood, plastic, and other recycled materials, making them both durable and sustainable. Among the leading players in this industry is a company that offers a wide range of composite pallet solutions that allow manufacturers to optimize their logistical processes.One of the major advantages of composite pallets is their low maintenance costs. They do not require as much upkeep as traditional wooden pallets, which can save businesses a considerable amount of time and money. Furthermore, composite pallets are extremely durable, ensuring that they can last a long time, even in tough manufacturing environments, and can withstand high-temperature conditions and exposure to chemicals.In addition to these benefits, composite pallets are also reusable, which significantly reduces waste and the environmental impact of the industry. Many businesses today are committed to sustainability and reducing their carbon footprint, and composite pallets are an excellent option for those who want to adopt more environmentally-friendly practices. The company behind the composite pallets takes pride in offering a product that aligns with the global effort to reduce waste and combat climate change.Another significant advantage of composite pallets is their scalability. The company’s composite pallets are designed to meet different types of logistical needs. They can be used for transporting items of different weights and sizes, making them versatile and practical. For instance, a business that wants to transport heavy machinery can use composite pallets as they can bear immense loads.Furthermore, the composite pallets come in different sizes and can be customized to suit each client's needs. With such a vast selection of composite pallets, manufacturers can choose the perfect option that aligns with their logistical needs and budget. The company's team of experts can work alongside clients to ensure that they get the best product for their requirements, even offering valuable insights based on decades of industry experience.In addition to the cost and environmental benefits, composite pallets also provide improved safety and hygiene standards. Unlike traditional wooden pallets that are prone to splintering and breakage, composite pallets are sturdy and have a smooth, non-slip surface that reduces the chances of accidents, thus improving employee safety. In addition, composite pallets are washable, and they don't hold on to moisture, which significantly reduces the risk of bacteria formation.As more businesses realize the benefits of composite pallets, the demand for these products will continue to grow. The company behind composite pallets is uniquely positioned to meet this growing demand through its innovative design, scalable and customizable products, and industry experience. Furthermore, the company’s high-quality standards ensure that clients receive a product that meets, if not exceeds, their expectations.In conclusion, composite pallets are becoming increasingly popular due to their cost-effectiveness, eco-friendly nature, improved safety, and hygiene qualities. On top of those qualities, the company's ability to provide scalable and customizable products and an experienced team of experts makes them the go-to option for manufacturers looking to optimize their logistics processes. As businesses look to reduce their expenses, as well as move towards sustainable practices, the composite pallets offered by the company serve as excellent options to achieve both of those goals.