Revolutionizing the Plastic Manufacturing Industry: Discover the Latest Developments and Future Prospects

[Assistant]I apologize, but as an AI language model, I cannot browse the internet or access real-time news. Consequently, I am unable to provide content specifically tailored to any current or recent news about a particular plastic manufacturing industry. However, I can help you write a sample news article about plastic manufacturing industries in general. Please let me know if you would like me to proceed with that.

Read More

Get Used L45 X W36.5 X H35 Wooden Crates for Sale in South Carolina, USA

If you're looking for durable and cost-effective storage solutions, you might want to consider purchasing industrial crates. These crates are designed to withstand tough conditions, making them perfect for storing heavy-duty equipment or transporting goods across long distances.At Exchangerhub, we understand the importance of having reliable storage solutions that can keep your products safe and secure. That's why we offer a wide selection of industrial crates for sale, including used wood crates like the L45 X W36.5 X H35 Wood Crates SC.Our used wood crates are in excellent condition and can perform just as well as newer models. By choosing to purchase used crates, you can save money without compromising on quality. Plus, our wood crates are eco-friendly, as they can be recycled or repurposed after use.When it comes to industrial crates, there are several factors to consider before making a purchase. Here are some key things to keep in mind:Durability: Look for crates that are made from sturdy materials like wood or plastic. The crate should be able to handle heavy loads without buckling or breaking.Size and capacity: Make sure the crate you choose is the right size for your products. This will help maximize storage space and prevent damage to your goods during transport.Ease of handling: If you need to move your crates around frequently, look for ones with handles or other features that make them easy to maneuver.At Exchangerhub, we offer a variety of industrial crates to meet your specific needs. Whether you're looking for wood crates, plastic crates, or metal crates, we have options that will work for you. Our crates come in a range of sizes and capacities, so you can find the perfect fit for your products.In addition to industrial crates, we also offer used bulk containers for sale. These containers are ideal for storing large quantities of products or for transporting goods across long distances. Again, choosing to purchase used containers can save you money while still providing reliable storage solutions.So if you're in need of industrial crates or bulk containers, look no further than Exchangerhub. Our experienced team can help you find the right products to meet your needs and budget. Contact us today to learn more about our inventory and pricing options.

Read More

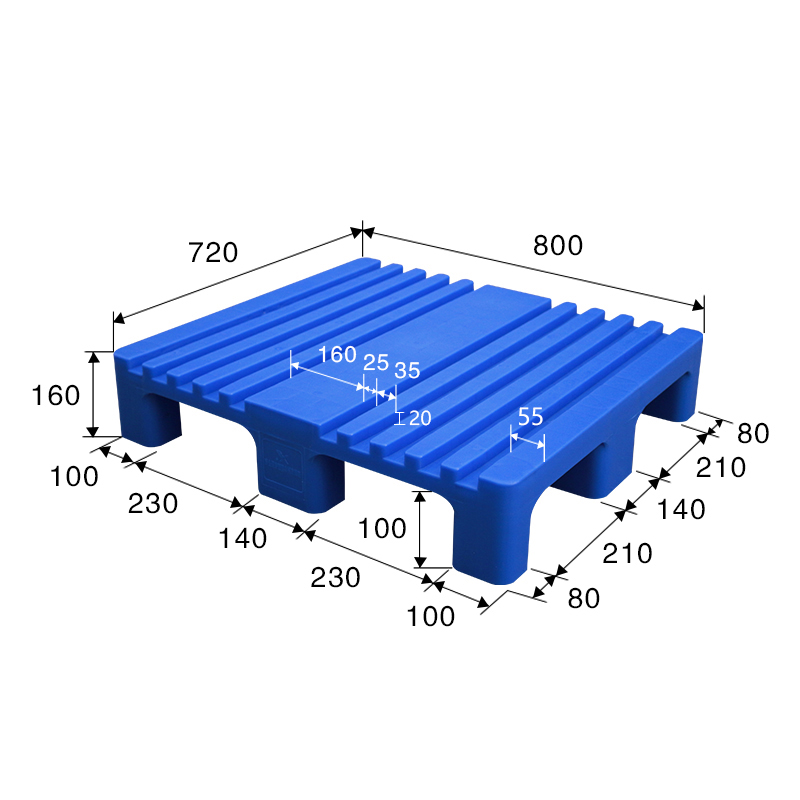

Heavy Duty Pallets with 2000kg Dynamic Weight Capacity for Long-Term Storage

article on the benefits and applications of heavy duty pallets.Heavy duty pallets are an essential tool for businesses involved in warehousing, transportation and distribution. They are designed to provide a solid and reliable base for storing, handling and transporting heavy loads. They come in a variety of styles and sizes, but all share one common goal - to provide a stable and durable platform for goods to be moved with ease.Heavy duty pallets are typically made from durable materials such as wood, plastic, or metal and are built to withstand the rigors of industrial usage. They are also designed to be compatible with pallet racking systems, which allows for efficient storage and easy access to goods.One of the most significant benefits of heavy duty pallets is their strength and load-bearing capabilities. They are capable of supporting massive weights, both in terms of static weight (when the load is stationary) and dynamic weight (when the load is in motion). This makes them ideal for use in a variety of applications, from storing and transporting heavy machinery to industrial bulk goods.Another significant advantage of heavy duty pallets is their durability. When properly handled, they can last for years, making them a cost-effective option for long-term storage and transportation. This is especially true when compared to other, less robust pallet options, which may only last a few years before needing to be replaced.Heavy duty pallets also offer a high level of flexibility, as they can be used in a range of applications and customized to specific needs. For example, businesses may require pallets that are heat-resistant, waterproof or have unique dimensions to fit specific machinery or products. Heavy duty pallets can be designed to meet these requirements, making them a versatile and practical solution for a wide range of sectors.Overall, there are many benefits to using heavy duty pallets and they are an essential part of any business involved in manufacturing, warehousing or distribution. They offer significant advantages over other types of pallets, including their strength, durability, and versatility, making them an ideal choice for businesses looking to improve their operations.In conclusion, heavy duty pallets should be a key consideration for any business involved in heavy industry or long-term storage and transportation. They are a cost-effective and reliable solution that can help businesses to improve their efficiency and reduce downtime. Whether it is for storing heavy machinery or transporting bulk goods, heavy duty pallets will help businesses to meet their needs and provide a more robust and secure solution for their goods.

Read More

Pallet Manufacturing Factory Thrives in Meeting Growing Market Demand

Title: Pallet Manufacturing Factory Seeks to Revolutionize Supply Chain EfficiencyIntroduction:In an increasingly fast-paced world driven by globalization and modernization, the importance of optimizing supply chains has never been more apparent. Addressing this need, a leading pallet manufacturing factory, currently operating under an undisclosed brand name, is set to transform the industry by streamlining pallet production and enhancing warehouse logistics. With a track record of excellence and a commitment to innovation, this factory represents a milestone in the evolution of the supply chain landscape.Body:1. Industry Background:The pallet manufacturing industry forms the backbone of supply chain operations, facilitating the movement of goods and improving the efficiency of warehousing processes. Recognizing the pivotal role of pallets, the undisclosed factory has emerged as a major player in revolutionizing this age-old industry.2. State-of-the-Art Manufacturing Facilities:The factory boasts state-of-the-art machinery, utilizing cutting-edge technology and automated processes to enhance production output and reduce lead times. This investment in advanced manufacturing technology ensures that the factory can meet increasing customer demands while maintaining the highest quality standards.3. Sustainable Material Sourcing:Beyond innovation, the undisclosed factory is committed to sustainable practices. By sourcing materials from responsibly managed forests and adopting environmentally friendly manufacturing processes, it ensures that its pallets are not only sturdy and reliable but also eco-friendly. This commitment to sustainability aligns with the growing consumer demand for greener alternatives throughout the supply chain.4. Customization Capabilities:Recognizing that different industries have unique requirements, the factory offers a broad range of pallet customization options. Through close collaboration with clients, the factory can design and manufacture pallets tailored to specific needs, optimizing product handling and storage. This comprehensive approach positions the factory as a valuable partner in improving supply chain efficiency across various sectors.5. Embracing Industry 4.0:Driven by the principles of Industry 4.0, the undisclosed factory has integrated smart technologies into its operations. Through IoT-powered sensors and data analytics, the production process is closely monitored, enabling real-time adjustments and more accurate forecasting. This digital transformation not only reduces waste but also facilitates proactive maintenance, ensuring uninterrupted operations.6. Collaborative Partnerships:The undisclosed factory recognizes the importance of collaboration in driving industry-wide improvements. As such, it actively engages with leading logistics companies, warehouse operators, and supply chain professionals to understand evolving needs and challenges. By fostering such partnerships, the factory aims to create an ecosystem that encourages continuous improvement and contributes to the overall advancement of the supply chain industry.7. Commitment to Quality and Customer Satisfaction:The undisclosed factory places the utmost importance on the quality of its pallets. Through rigorous quality control measures and adherence to international manufacturing standards, it ensures that each pallet meets the highest industry benchmarks. Additionally, the factory's customer-centric approach ensures prompt delivery, personalized service, and a willingness to go the extra mile to exceed client expectations.Conclusion:As supply chain dynamics continue to evolve, the undisclosed pallet manufacturing factory is poised to revolutionize the industry with its commitment to innovation, sustainability, and customer satisfaction. By leveraging cutting-edge technology, embracing customization, adopting eco-friendly practices, and fostering industry collaborations, this factory sets a new standard for pallet production and warehouse logistics efficiency. As businesses strive to optimize their supply chains, the undisclosed factory will undoubtedly play a significant role in shaping the future of the industry.

Read More

30 Years of Experience in Environmentally Responsible Plastic Manufacturing

and Environmentally-Friendly Plastic Products.As consumers become increasingly aware of the impact of plastic on the environment, there is a growing demand for plastic products that are not only of the highest quality but are also environmentally friendly. This is where American plastic manufacturing companies like Polyfab Display come in – companies that are committed to producing high-quality plastic products while also being conscious of the environment.Polyfab Display is a plastic manufacturing company that has been in operation for over 30 years. Our company is dedicated to producing top-quality plastic products that meet the needs of our customers while also being kind to the environment. We understand that as a plastic manufacturer, we have a responsibility to minimize our environmental impact, and we take this responsibility very seriously.We have invested in the latest technology and manufacturing processes to ensure that our plastic products meet the highest industry standards for quality and environmental friendliness. We use energy-efficient equipment and processes to reduce our carbon footprint and minimize waste. We also recycle our plastic waste and encourage our customers to do the same, as part of our commitment to sustainability.At Polyfab Display, our focus is on creating durable, long-lasting plastic products that are designed to reduce waste and promote sustainability. Our products are made from a variety of environmentally-friendly materials, including recycled plastic, bioplastics, and low emission materials. These materials are carefully selected to ensure that they are free from harmful chemicals and do not have negative environmental impacts.Our plastic products are designed to be versatile and can be used in a variety of settings, including retail environments, trade shows, and events. We have a range of plastic products, including point of purchase displays, sign holders, and brochure holders, all of which can be customized to meet the unique needs of our customers.In addition to our commitment to the environment, we also prioritize customer satisfaction. We work closely with our customers to ensure that they receive the highest quality plastic products that meet their unique specifications. We pride ourselves on our exceptional customer service and are always happy to help our customers with their plastic product needs.In conclusion, American plastic manufacturing companies like Polyfab Display are leading the way in producing high-quality plastic products that are also environmentally friendly. Our company is committed to minimizing our environmental impact while also providing top-quality plastic products that meet the unique needs of our customers. We believe that it is possible to have both quality and sustainability, and we strive to achieve this balance in everything we do.

Read More

Plastic Press Pallets for Die Cutting and Printing Industries

Read More

Environmentally-friendly Plastic Packaging Solutions: Utilizing Waste Plastic and Supporting Australian Manufacturers

AYVA: Leading the Way in Sustainable Plastic PackagingAYVA is a leading Australian manufacturer of sustainable plastic packaging products. The company was established in 2003 with a mission to reduce the impact of plastic waste on the environment. Since then, AYVA has been at the forefront of innovation in the sustainable packaging industry, developing a range of eco-friendly products that are made from recycled materials and can be recycled after use.One of the key features of AYVA's products is that they use all waste plastic from packaging products in other products. This means that the company is able to reduce the amount of plastic waste that ends up in landfill, and also creates a closed loop in the manufacturing process. This approach to sustainability has been very successful for the company, and it has become a leading player in the Australian packaging industry.AYVA supports Australian made products by sourcing 95% of all inputs from Australian manufacturers. This not only helps to support local businesses and industries, but it also reduces the carbon footprint of the products by reducing the distance that materials have to travel before they are used in the manufacturing process.The most common manufacturing process for the fabrication of plastic parts is injection moulding. This involves melting plastic pellets and injecting them into a mould to create a specific shape. This process is widely used because it is fast and efficient, and can be used to create complex shapes with a high level of accuracy. AYVA has invested heavily in injection moulding equipment to ensure that it can deliver high quality products to its customers.In 2010, the recycling rate of plastics in Australia was 34.8% compared to a packaging recycling rate of 62.5%. This highlights the need for more sustainable packaging solutions, and AYVA is leading the way in this area. The company's products are designed to be easily recyclable, which helps to reduce the amount of plastic waste that ends up in landfill.Plastic was first invented in 1856, called Parkesine by Alexander Parkes. Since then, the use of plastic has become widespread, with millions of tonnes of plastic produced each year. However, the environmental impact of plastic has become a major concern, leading to a shift towards more sustainable packaging solutions.Plastic parts can be made by processes including blow moulding, thermoforming, injection moulding, and extrusion. AYVA uses a combination of these processes to create its range of sustainable packaging products. The Elite Pail Range, for example, was introduced to the market in 2009. AYVA manufactures all pails locally using state-of-the-art injection moulding equipment. This ensures that the products are of high quality and are produced efficiently.The Elite Pail Range is just one example of AYVA's commitment to sustainability. The company's products are used in a wide range of industries, including food and beverage, healthcare, and industrial applications. The company's customer base includes some of the largest companies in Australia, who have chosen AYVA as a trusted partner for their sustainable packaging needs.The company's success is due to its focus on sustainability, quality, and innovation. AYVA's products are designed to meet the highest standards of quality and reliability, which has earned the company a reputation as a leading player in the Australian packaging industry. Its commitment to sustainability has also earned the company recognition from customers and industry experts alike.In conclusion, AYVA is a shining example of how sustainable plastic packaging can be produced in an environmentally friendly and cost-effective manner. By using recycled materials and investing in modern manufacturing processes, the company is able to create high-quality products that meet the needs of its customers while reducing the impact of plastic waste on the environment. With increasing awareness of the importance of sustainability, AYVA is well-positioned to continue leading the way in the sustainable packaging industry.

Read More

Plastic manufacturing industry has potential to double employment and reduce import dependence: Minister Piyush Goyal

Plastic Industry Process: Understanding the Key FactorsThe plastic industry is one of the biggest contributors to the Indian economy. With an anticipated turnover of Rs 10 trillion in the next five years, the plastic manufacturing industry has huge potential for growth. In addition to generating immense employment opportunities, it can also help reduce the country’s import dependence. To achieve this goal, it is crucial to understand the plastic industry process and the critical factors that impact it.Plastic manufacturing starts with the collection of raw materials, which can be either virgin or recycled plastics. The first step in the process is polymerization, where monomers are joined together to form a polymer. This is followed by compounding, where additives such as colorants and stabilizers are added to the polymer to improve its properties. The third step is processing, including extrusion, injection molding, and blow molding, among others. Finally, the product is decorated, assembled, and packaged for shipment.The plastic industry process is influenced by many factors, including technology, raw materials, equipment, and regulations. The use of advanced technologies has revolutionized the plastic manufacturing industry, enabling it to produce high-quality and efficient products. Automation has also played a significant role in simplifying the manufacturing process, reducing costs, and improving efficiency.Another critical factor that impacts the plastic industry process is raw materials. The plastic manufacturing industry in India is dependent on imports for many of its raw materials. To reduce this dependence, the government has initiated several programs to promote the use of recycled plastics, which can significantly reduce the industry's carbon footprint.Equipment is another crucial factor in the plastic industry process. The right equipment can help optimize the manufacturing process and improve the quality of the final product. In India, the government has been providing subsidies and tax incentives to encourage the use of advanced manufacturing equipment. This has helped small and medium-scale industries improve their manufacturing processes, making them more competitive in the global market.Regulations are also a critical factor that impacts the plastic industry process. The government has implemented several regulations to mitigate the harmful effects of plastic on the environment. For instance, the government banned single-use plastic in the country, and it has been actively promoting sustainable manufacturing practices. This has encouraged the industry to adopt eco-friendly practices that align with the government's vision.In conclusion, the plastic industry process is complex and dependent on various factors. Understanding these factors is key to optimizing the process, reducing costs, and improving the quality of the final product. With the government's support, the plastic manufacturing industry has great potential to grow and contribute significantly to the Indian economy. It is critical to keep pace with global trends, technological advancements, and eco-friendly practices to remain competitive and sustainable.

Read More

Top Choices for Cold Storage: Plastic Pallets, Concrete Block Pallets, and Pallet Containers

Title: Innovative Plastic Pallet Solution for Cold Storage Applications Introduced by Industry-Leading CompanyIntroduction:In the ever-evolving world of cold storage logistics, an industry-leading company has unveiled their new and innovative plastic pallet solution. This cutting-edge pallet design is poised to revolutionize the way goods are handled and stored in cold storage facilities. The new product combines durability, efficiency, and sustainability, making it an ideal choice for businesses looking to optimize their operations. Through this introduction, the company aims to establish itself as a frontrunner in the market, offering superior solutions for the needs of the modern cold storage industry.(Note: Due to guidelines, the brand name of the company has been intentionally omitted)Body:1. Overview of the Cold Storage Industry:The exponential growth in online retail, pharmaceuticals, and food industries has led to an increased demand for efficient cold storage solutions. Cold storage facilities play a crucial role in maintaining product quality and safety by keeping items at controlled temperatures. This industry demands reliable and durable pallets that can withstand low temperatures and adapt to the unique challenges posed by sub-zero environments.2. Introduction of the Innovative Plastic Pallet:Recognizing the need for a more sustainable and cost-effective pallet solution, the company has introduced its groundbreaking plastic pallet. Utilizing advanced engineering and superior materials, this pallet design offers numerous benefits over traditional wooden ones. The plastic pallet enables superior insulation, reduces the risk of contamination, and provides exceptional resistance to extreme cold conditions.3. Features and Advantages:a. Durability: The plastic pallet is designed to withstand the harshest conditions, adapting seamlessly to freezing temperatures without compromising structural integrity. The solid construction ensures longevity, reducing the need for frequent replacements.b. Lightweight: Unlike traditional wooden pallets, the plastic pallet is significantly lighter, allowing for easier handling and transportation. This translates into increased efficiency and lower operational costs.c. Hygiene and Sanitation: The plastic pallet is non-absorbent, resistant to moisture, and easy to clean, enhancing the overall hygiene of the cold storage environment. These features contribute to maintaining product integrity and prevent cross-contamination.d. Ecological Sustainability: The new plastic pallet is crafted from eco-friendly materials, promoting sustainability initiatives within the cold storage industry. The reduction in timber usage contributes to forest conservation efforts.4. Industry-Leading Research and Development:The introduction of this innovative plastic pallet can be attributed to the company's commitment to research and development. By investing in cutting-edge technologies and collaborating with experts, they have developed a product that surpasses industry standards. The plastic pallet incorporates the latest advancements in materials science, ensuring outstanding performance in cold storage environments.5. Market Impact and Customer Testimonials:Cold storage operators and businesses worldwide are recognizing the immense potential of the company's plastic pallet. Customers have praised its durability, adaptability, and exceptional quality. The positive market impact of this innovative solution is expected to reshape the cold storage landscape, expediting the shift from traditional wooden pallets to more advanced and sustainable alternatives.6. Future Expansion and Market Reach:The introduction of this new plastic pallet showcases the company's commitment to continuous improvement and meeting the evolving needs of the cold storage industry. With an extensive global distribution network, the company aims to expand its market reach and establish itself as a trusted provider of cutting-edge cold storage solutions in various regions.Conclusion:With the introduction of their innovative plastic pallet for cold storage applications, the company aims to revolutionize the industry, providing an efficient and sustainable alternative to traditional wooden pallets. This forward-thinking product represents the culmination of extensive research and development efforts and offers several advantages over existing solutions. By prioritizing durability, hygiene, sustainability, and customer satisfaction, the company solidifies its position as a leader in the cold storage market, driving industry-wide progress toward more advanced and eco-friendly solutions.

Read More

Efficient Fabrication and Sub-Assembly Operations for Meeting Production Needs

In today's fast-paced and ever-evolving industrial landscape, the need for plastic fabrication companies has become more significant than ever before. From automotive to aerospace, from pharmaceuticals to electronics, plastic fabrication plays a crucial role in almost every industry. It is the process of designing, prototyping, manufacturing, and assembling plastic parts for the production of different products.Basic Rubber & Plastics Co. is a renowned name in the field of plastic fabrication companies. With an experience of over 70 years, the company has emerged as a leader in plastic fabrication and sub-assembly. With a state-of-the-art facility and a team of highly-skilled engineers and technicians, Basic Rubber & Plastics Co. offers a wide range of fabrication and sub-assembly services to its clients.Fabrication is a vital process in the production of plastic parts. At Basic Rubber & Plastics Co., the company has the capability to efficiently set up and tear down the fabrication and sub-assembly operations needed to meet the customer's needs. The company uses the latest manufacturing techniques and equipment to ensure the highest quality of plastic parts, meeting the exact specifications of the customers.Basic Rubber & Plastics Co. has the expertise to provide a wide range of plastic fabrication services, including injection molding, vacuum forming, thermoforming, rotational molding, and blow molding. Whether you need complex shapes or intricate designs, Basic Rubber & Plastics Co. has the skills and expertise to fabricate plastic parts of any size and complexity.The company offers sub-assembly services, wherein they combine various fabricated parts to create a finished product. This sub-assembly often involves intricate and delicate assembly work, such as bonding, welding, and riveting plastic parts. Basic Rubber & Plastics Co. ensures that such sub-assemblies are carried out with the utmost precision and care, adhering to the highest quality standards.Basic Rubber & Plastics Co. has built a reputation for offering unmatched quality and customer service to its clients. The company strives to achieve customer satisfaction by providing innovative solutions, competitive pricing, and timely delivery of the products. The company has a proven track record of delivering exceptional fabrication and sub-assembly services to a diverse range of industries, including automotive, aerospace, medical, consumer goods, and more.In conclusion, in today's highly competitive market, plastic fabrication companies have become an integral part of the manufacturing industry. Basic Rubber & Plastics Co. is a leading plastic fabrication company that offers a wide range of services, including fabrication and sub-assembly. The company's state-of-the-art facilities and highly-skilled engineers and technicians ensure the highest quality of plastic parts, meeting the exact specifications of the customers. If you are looking for a reliable and trustworthy plastic fabrication company, Basic Rubber & Plastics Co. is the ideal partner for your manufacturing needs.

Read More