Innovative printing solutions for pallets in the tobacco industry

By:Admin

Printing on pallets can be a challenging task for several reasons. Pallets are not designed for printing, and there are usually issues related to their size and surface. However, with the Pallet Speria 104 Printer, printing on pallets has become a hassle-free experience. The Pallet Speria 104 printer combines high-resolution printing technology with a versatile design to provide an efficient solution for printing on a variety of pallets.

The Pallet Speria 104 Printer is developed by a leading printing technology company that specializes in providing custom printing solutions to various industries, including logistics, food and beverage, pharmaceutical, and retail. The printer is equipped with the latest printing technology, enabling it to print high-quality images and texts on pallets in a matter of seconds. The Pallet Speria 104 Printer is compatible with multiple ink types and colors, making it possible to print on different materials, including wood, plastic, and metal.

One of the most significant advantages of the Pallet Speria 104 Printer is its versatile design. The printer is designed in a way that it can work seamlessly with most types of pallets, regardless of their size and surface. This means that companies can use the printer to print on a wide range of pallets, including tobacco pallets and Rapida 106 pallets, without having to worry about compatibility issues.

Companies that use the Pallet Speria 104 Printer will benefit from its efficient production process. The printer is designed to work with minimal intervention from operators, reducing the time and effort required for printing on pallets. Moreover, the printer's high-speed and high-resolution printing capabilities ensure that companies can produce high-quality printed pallets in large quantities, resulting in increased productivity and reduced costs.

Another key advantage of the Pallet Speria 104 Printer is its ease of use. The printer is user-friendly, and operators can easily operate it using a built-in touch screen display. Additionally, the printer's ink cartridges are easy to replace, minimizing downtime and ensuring that operators can quickly resume printing operations.

In conclusion, the Pallet Speria 104 Printer is an innovative printing solution that provides a versatile, efficient, and easy-to-use solution for printing on pallets. Companies that use this printer can benefit from its high-resolution, high-speed, and flexible printing capabilities, resulting in increased productivity and reduced costs. Whether it's tobacco pallets, Rapida 106 pallets, or any other type of pallet, the Pallet Speria 104 Printer provides the best solution for printing on them.

Company News & Blog

Top-rated Crates Manufacturer: Quality Products for Various Needs

Title: Leading Crates Manufacturer Expands Product line to Meet Growing DemandIntroduction:In response to the rising demand for high-quality crates across various industries, a renowned crates manufacturing company is expanding its product line to cater to the evolving market needs. The company, with its extensive experience and dedication to innovation, has become a trusted name in the industry for its durable and customizable crates. This strategic move aims to meet the increasing demand while ensuring customer satisfaction through a wider range of products.Expansion of Product Line:The leading crates manufacturer recognizes the importance of adapting to changing market dynamics. By expanding its product line, the company intends to offer an even more comprehensive array of crates, accommodating diverse industry requirements. This expansion includes the introduction of several new crate designs that are developed with a focus on durability, versatility, and functionality.1. Customizable Crates:Understanding that every industry and business has unique needs, the manufacturer will now provide customized crates. These crates can be tailored to fit specific dimensions and requirements. This customization option will allow businesses to maximize their storage and transportation efficiency, promoting seamless operations.2. Heavy-Duty Crates:Recognizing the demand for sturdier crates to withstand rigorous handling, the manufacturer will be introducing heavy-duty crates. These crates will be made from high-quality materials to ensure their durability and resistance to impact. This addition will cater to industries such as construction, agriculture, and manufacturing, where the transportation of heavier goods is common.3. Stackable and Nestable Crates:Efficient space utilization is a key concern for many businesses. Therefore, the company will now offer stackable and nestable crates, providing easy storage and optimized use of available space. These crates will enable businesses to streamline their operations by reducing storage costs and enhancing logistics processes.4. Ventilated and Perforated Crates:In response to the needs of industries requiring proper airflow and ventilation for their goods, the manufacturer will introduce ventilated and perforated crates. These crates will ensure proper air circulation, preventing moisture build-up and potential damage to the stored items. This innovation will benefit industries such as agriculture, pharmaceuticals, and food processing.5. Collapsible Crates:Recognizing the need for efficient storage when crates are not in use, the manufacturer is planning to introduce collapsible crates. These crates will be foldable, allowing businesses to save valuable space when not in use. This feature will prove especially useful for industries engaging in international shipments or those requiring periodic storage.Commitment to Sustainable Practices:This expansion in the product line also aligns with the manufacturer's commitment to sustainable practices. The company recognizes the importance of minimizing the environmental impact of its operations and products. Therefore, the new range of crates will incorporate eco-friendly materials and production techniques wherever possible. By offering sustainable options, the manufacturer aims to contribute to the global sustainability goals while providing efficient solutions to businesses.Conclusion:The expansion of the leading crates manufacturer's product line signifies its dedication to meeting the evolving demands of various industries. With a focus on customization, durability, functionality, and sustainable practices, the company aims to provide an extensive range of crates suitable for diverse applications. By accommodating the needs of businesses seeking efficient storage and transportation solutions, the manufacturer solidifies its position as a reliable partner for companies across sectors. This strategic move will enhance the company's growth potential while ensuring customer satisfaction through innovative and high-quality products.

Efficient Fabrication and Sub-Assembly Operations for Meeting Production Needs

In today's fast-paced and ever-evolving industrial landscape, the need for plastic fabrication companies has become more significant than ever before. From automotive to aerospace, from pharmaceuticals to electronics, plastic fabrication plays a crucial role in almost every industry. It is the process of designing, prototyping, manufacturing, and assembling plastic parts for the production of different products.Basic Rubber & Plastics Co. is a renowned name in the field of plastic fabrication companies. With an experience of over 70 years, the company has emerged as a leader in plastic fabrication and sub-assembly. With a state-of-the-art facility and a team of highly-skilled engineers and technicians, Basic Rubber & Plastics Co. offers a wide range of fabrication and sub-assembly services to its clients.Fabrication is a vital process in the production of plastic parts. At Basic Rubber & Plastics Co., the company has the capability to efficiently set up and tear down the fabrication and sub-assembly operations needed to meet the customer's needs. The company uses the latest manufacturing techniques and equipment to ensure the highest quality of plastic parts, meeting the exact specifications of the customers.Basic Rubber & Plastics Co. has the expertise to provide a wide range of plastic fabrication services, including injection molding, vacuum forming, thermoforming, rotational molding, and blow molding. Whether you need complex shapes or intricate designs, Basic Rubber & Plastics Co. has the skills and expertise to fabricate plastic parts of any size and complexity.The company offers sub-assembly services, wherein they combine various fabricated parts to create a finished product. This sub-assembly often involves intricate and delicate assembly work, such as bonding, welding, and riveting plastic parts. Basic Rubber & Plastics Co. ensures that such sub-assemblies are carried out with the utmost precision and care, adhering to the highest quality standards.Basic Rubber & Plastics Co. has built a reputation for offering unmatched quality and customer service to its clients. The company strives to achieve customer satisfaction by providing innovative solutions, competitive pricing, and timely delivery of the products. The company has a proven track record of delivering exceptional fabrication and sub-assembly services to a diverse range of industries, including automotive, aerospace, medical, consumer goods, and more.In conclusion, in today's highly competitive market, plastic fabrication companies have become an integral part of the manufacturing industry. Basic Rubber & Plastics Co. is a leading plastic fabrication company that offers a wide range of services, including fabrication and sub-assembly. The company's state-of-the-art facilities and highly-skilled engineers and technicians ensure the highest quality of plastic parts, meeting the exact specifications of the customers. If you are looking for a reliable and trustworthy plastic fabrication company, Basic Rubber & Plastics Co. is the ideal partner for your manufacturing needs.

Revolutionary New Pallet Design Boosts Efficiency and Simplifies Material Handling Processes

Innovative Continuous Feed Pallet Revolutionizing Warehouse Efficiency[Company Introduction]In the ever-evolving world of warehousing and logistics, efficiency and productivity are the keys to success. With the increasing demands of e-commerce and global supply chains, finding innovative solutions to streamline operations is more crucial than ever. Witnessing this need for efficiency, [Company Name], a leading provider of cutting-edge warehouse equipment, has unveiled their latest game-changing creation – the Continuous Feed Pallet.[Continuous Feed Pallet]The Continuous Feed Pallet, developed by [Company Name], is set to revolutionize warehouse operations worldwide. Designed with advanced technology and a deep understanding of industry requirements, this innovative pallet system offers numerous benefits that will enhance productivity, reduce downtime, and optimize workflow.At its core, the Continuous Feed Pallet incorporates a unique conveyor system into its design. This conveyor mechanism enables a seamless flow of pallets through the warehouse, eliminating the need for manual labor and maximizing efficiency. By utilizing this system, warehouses can achieve a continuous, uninterrupted supply of goods, significantly reducing the time and effort required to move pallets from one location to another.Furthermore, the Continuous Feed Pallet is built to adapt to various warehouse layouts and configurations. The modular design enables easy installation and customization, ensuring compatibility with existing infrastructure. This versatility allows warehouses to integrate the system seamlessly without major disruptions or costly modifications.In addition to its convenience and adaptability, the Continuous Feed Pallet prioritizes safety. Incorporating state-of-the-art sensors and intelligent control systems, the pallets guarantee a secure and reliable transportation process. The sensors detect obstacles or potential hazards, automatically adjusting the speed and direction to avoid any accidents. This smart feature not only protects workers from injuries but also prevents damage to goods and machinery.Moreover, the Continuous Feed Pallet system is designed to optimize warehouse space utilization. By utilizing the vertical space and allowing multiple levels of pallet movements, it effectively maximizes the storage capacity of the facility. In a time where warehousing and square footage costs are skyrocketing, this feature provides a cost-effective solution for businesses looking to expand their operations without the need for additional real estate.Furthermore, the Continuous Feed Pallet supports comprehensive inventory management by integrating seamlessly with existing warehouse management systems (WMS). By providing real-time data on the location and movement of each pallet, the system enables precise tracking and inventory control. This level of accuracy minimizes human error and ensures a more efficient allocation and retrieval of goods when needed, enabling businesses to meet the demands of their customers promptly.[Company Name] brings years of experience and expertise to the table, making them the leading contender in innovative warehouse solutions. Their commitment to quality and customer satisfaction is evident in the Continuous Feed Pallet, which has been meticulously engineered and optimized to provide a cutting-edge solution to one of the most pressing challenges faced by warehouses today.With the Continuous Feed Pallet, [Company Name] hopes to revolutionize the way warehouses operate. By promoting uninterrupted workflows, enhancing safety measures, optimizing space utilization, and seamlessly integrating with existing systems, this groundbreaking pallet system will undoubtedly redefine warehouse efficiency and productivity.As the global supply chain continues to expand, organizations that embrace technological advancements like the Continuous Feed Pallet will undoubtedly gain a competitive edge. With the rise of e-commerce and the increasing demands of customers for faster deliveries, this innovation promises to be a game-changer in the world of warehousing. [Company Name] has once again proved its commitment to driving industry progress and helping businesses thrive in an ever-evolving marketplace.

Unveiling the Harmful Effects of Plastic on the Environment

in your article.The Problem with Plastics: Finding Sustainable Solutions from Plastic Parts SuppliersPlastics have become an integral part of our everyday lives. From food packaging to medical equipment, these materials have proven their durability and flexibility. However, the convenience that plastics offer comes at an environmental cost.Plastic waste has become a global problem, with plastic debris now littering oceans and polluting ecosystems. A report by the World Economic Forum revealed that by 2050, there could be more plastics in the oceans than fish. Governments, organizations, and individuals are coming together to address this issue, and one key player in this effort is the plastic parts suppliers.Plastic parts suppliers are companies that specialize in the manufacturing and distribution of plastic components that are used in various industries such as automotive, consumer goods, and construction. These suppliers have a critical role to play in finding sustainable solutions to the plastic waste problem.One way plastic parts suppliers can contribute to environmental sustainability is by using recycled plastics. Recyclable plastics, such as polyethylene terephthalate (PET), can be used to make new products. The use of recycled plastics reduces the amount of plastic sent to landfills and helps to conserve natural resources.Another way plastic parts suppliers can promote sustainability is by reducing the amount of plastic used in their products. Lightweight plastics, such as polycarbonate and nylon, are being used increasingly in automotive and consumer goods. These materials are not only more energy-efficient but also require fewer resources to produce.In addition to minimizing plastic waste, plastic parts suppliers can also contribute to environmental sustainability by adopting eco-friendly manufacturing practices. These practices include reducing energy consumption, minimizing water usage, and implementing waste reduction programs in their production processes.The role of plastic parts suppliers in promoting sustainability does not end there. These companies can also encourage their customers to adopt eco-friendly practices. By providing them with sustainable alternatives such as biodegradable plastics or reusable packaging solutions, plastic parts suppliers can support their customers in achieving their sustainability goals.In conclusion, plastics are an essential component of modern life, but their impact on the environment cannot be ignored. Plastic parts suppliers have a critical role to play in addressing this issue. By using recycled plastics, reducing plastic usage, adopting eco-friendly manufacturing practices, and providing sustainable alternatives to their customers, these companies can contribute significantly to environmental sustainability. Together, we can all work towards a cleaner, healthier planet.

Effective Methods to Prevent, Inhibit and Remediate Mold on Wood Pallets

Wooden pallets have been used in industries worldwide for transporting and storing goods for ages. They are economical, environmentally friendly, and reusable. However, one of the significant challenges that come with using wooden pallets is the growth of mold. Pallet mold can wreak havoc on the products being transported, leading to losses for the manufacturers.Mold growth on pallets is caused by various factors like humidity, temperature, and moisture content. Once mold growth starts, it can spread quickly, leading to a complete infestation that may render the pallets unusable. Manufacturers need to take steps to prevent, inhibit and remediate pallet mold to reduce losses and ensure product safety.Preventing Pallet MoldPreventing mold growth on wooden pallets requires manufacturers to be proactive in their approach. Here are some ways to prevent pallet mold:1. Dry pallets thoroughly: Before using wooden pallets, ensure they are thoroughly dry. Moisture is a significant contributor to mold growth, and ensuring the pallets are dry can prevent mold growth.2. Proper storage: If pallets are not in use, they should be stored in a dry, well-ventilated area. If stored outside, cover the pallets with a tarp to prevent water from getting in.3. Use mold-resistant pallets: Some pallets come specifically treated with chemicals like borates to inhibit mold growth.Inhibiting Pallet MoldManufacturers may not always be able to prevent mold growth on pallets. However, inhibiting mold growth can help reduce losses. Here are some ways to inhibit pallet mold:1. Regular cleaning: Regularly cleaning the pallets can inhibit mold growth. Use a mild cleaning solution to wash the pallets, then air dry them in a well-ventilated area.2. Use anti-microbial coatings: Anti-microbial coatings can be applied to pallets to inhibit mold growth. These coatings can be applied using a spray method or a dipping method.3. Use pallet covers: Pallet covers can be used to protect the pallets from moisture and humidity, inhibiting mold growth.Remediating Pallet MoldIf mold growth is detected on wooden pallets, remediation is necessary to prevent it from spreading. Here are some ways to remediate pallet mold:1. Surface cleaning: Use a mild cleaning solution and a brush to clean the pallet surface thoroughly. Then, air dry the pallets.2. Secondary cleaning: If the mold growth is extensive, secondary cleaning may be necessary. Use a stronger solution and a pressure washer to clean the pallets.3. Fumigation: Fumigation may be necessary for severe cases of mold growth. This involves sealing the pallets in an airtight space and using chemicals to kill the mold.In conclusion, pallet mold is a significant concern for manufacturers, but steps can be taken to prevent, inhibit and remediate it. By being proactive, manufacturers can prevent mold growth on their pallets. If mold growth occurs, inhibiting its spread and remediating it can help reduce losses and ensure product safety. Manufacturers should ensure they have a pallet mold prevention plan in place.

Heavy Duty Pallets for Long-Term Storage with High Weight Capacity and Durability

Storage Solutions: The Benefits of Choosing Rackable Plastic PalletsWhen it comes to storing and transporting goods, choosing the right pallet is crucial. Not only does it need to be durable enough to withstand the weight of your products, but it also needs to fit comfortably in your storage or racking system.One type of pallet that has become increasingly popular in recent years is the rackable plastic pallet. These pallets offer a range of benefits that make them a great choice for long-term storage solutions. Whether you're storing heavy machinery parts or delicate electronics, here's why rackable plastic pallets might be the perfect fit for your needs.Durable and Long-LastingOne of the biggest benefits of rackable plastic pallets is their durability. Made from high-density polyethylene or HDPE, these pallets are designed to withstand heavy loads and resist impact, wear, and tear. They can hold up to 2000kg of dynamic weight and 10,000kg of static weight, making them ideal for storing heavy products.What's more, because they're made from plastic, they're resistant to moisture, chemicals, and UV rays. This means that they won't absorb moisture or contaminants, making them safer for storing food, pharmaceuticals, and other sensitive products.Easy to Handle and TransportAnother benefit of rackable plastic pallets is that they're lightweight and easy to handle. This makes them easier to lift and transport than heavy wooden pallets, which can be difficult to move around.Plus, because they're made from plastic, they don't splinter or crack like wood can. This makes them safer to handle without the risk of injury or damage to the product. And because they're stackable, they take up less space when not in use, making them easier to store.Versatile and CustomizableRackable plastic pallets come in a variety of styles and sizes to suit your needs. Whether you need a smooth top or a grill top, there's a pallet that fits your requirements. And because they're made from plastic, they can be easily customized with logos, colors, or other branding elements.Furthermore, rackable plastic pallets can be designed to fit specific racking systems. This means that you can be sure that your pallets will fit perfectly in your storage or racking system, reducing the risk of damage to your products.Environmentally FriendlyFinally, rackable plastic pallets are environmentally friendly. Unlike wooden pallets, which can be difficult to dispose of and can contribute to deforestation, plastic pallets are fully recyclable. They can be melted down and reused to create new pallets or other plastic products.This makes them a great choice for companies looking to reduce their environmental footprint and embrace sustainable practices.ConclusionWhen it comes to storing and transporting heavy or delicate products, choosing the right pallet is essential. Rackable plastic pallets offer a range of benefits that make them an attractive choice for long-term storage solutions.From their durability and lightweight design to their customizability and environmental friendliness, there are many reasons why rackable plastic pallets might be the perfect fit for your needs. So why not explore the options available and see how they could help you store and transport your goods more efficiently?

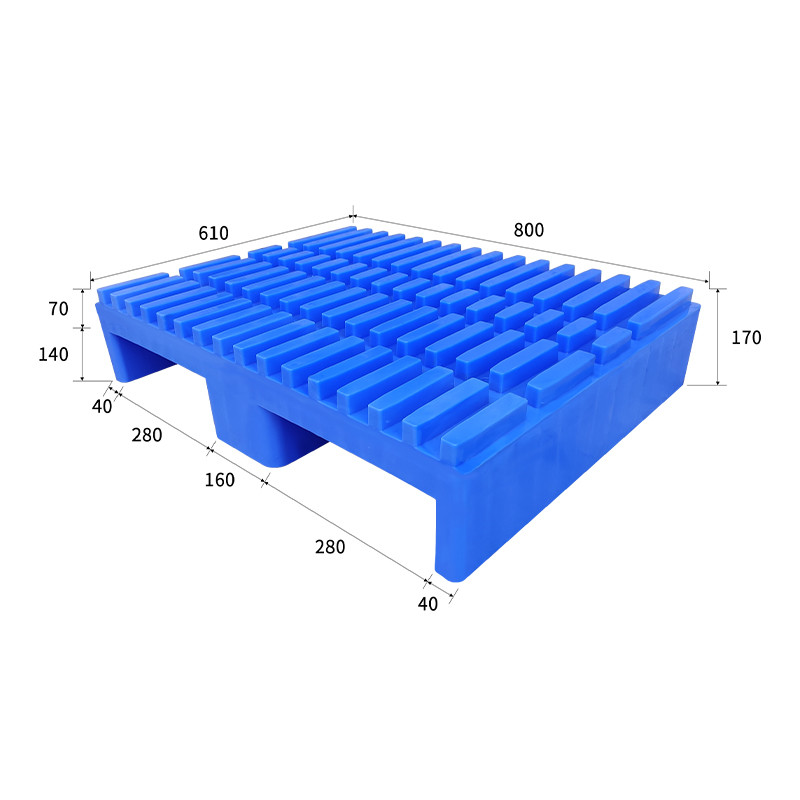

High-Quality Large Stackable Plastic Pallet for Heavy-Duty Static Load

Manufacturer of Heavy Duty Large Stackable Plastic Pallet Introduces Innovative Product to the MarketThe market for packaging and material handling solutions continues to evolve as companies seek more innovative ways to transport goods safely and efficiently. One product that has become increasingly popular in recent years is the stackable plastic pallet, which provides a durable and cost-effective solution for companies that need to move large quantities of goods. Leading the way in this industry is the Heavy Duty Large Stackable Plastic Pallet, which is manufactured by a company that has been a staple in the packaging industry for many years.The Heavy Duty Large Stackable Plastic Pallet is a product that has been designed with the needs of modern businesses in mind. It is a versatile and cost-effective solution that can be used in a variety of industries, including food and beverage, pharmaceuticals, automotive and many more. This innovative packaging solution is built to last, as it is made from high-quality plastic material that can withstand heavy loads and a range of weather conditions.One of the key advantages of the Heavy Duty Large Stackable Plastic Pallet is its ability to stack. This makes it easy to transport large quantities of goods, as each pallet can be stacked on top of one another, creating a compact and organized load that can be loaded and unloaded with ease. The pallet's design is also stackable, so it requires less space for storage, which can save businesses money on storage costs.In addition to its strength and durability, the Heavy Duty Large Stackable Plastic Pallet is also environmentally friendly. It is made from recycled plastic materials, which means that it does not require virgin materials to be produced. This reduces the carbon footprint of the product, which is an important consideration for modern businesses that want to reduce their impact on the environment.The Heavy Duty Large Stackable Plastic Pallet is also easy to clean, which makes it ideal for companies that need to ensure that their products are hygienic and free from contamination. The pallet can be easily cleaned with a pressure washer or a simple water hose, which saves time and reduces labor costs.The manufacturer of Heavy Duty Large Stackable Plastic Pallet has a long-standing reputation for quality and innovation in the packaging industry. They are committed to providing their customers with the best products and services possible, which is why they have invested heavily in research and development to create products like the Heavy Duty Large Stackable Plastic Pallet.The company is based in [location], and they have a team of experienced engineers and designers who work tirelessly to ensure that their products meet the highest standards of quality and safety. They use only the best materials and manufacturing techniques to create products that are both durable and cost-effective, which has earned them a loyal customer base around the world.Despite the challenges posed by the pandemic, the manufacturer of Heavy Duty Large Stackable Plastic Pallet has managed to continue supplying their products to businesses around the world. They have implemented strict safety protocols to ensure that their staff and customers are safe, and they have worked hard to maintain their high levels of customer service even during these difficult times.In conclusion, the Heavy Duty Large Stackable Plastic Pallet is an innovative and cost-effective solution that is ideal for businesses that need to transport large quantities of goods. It is durable, environmentally friendly, and easy to clean, which makes it an excellent investment for businesses in a range of industries. The manufacturer of this product has a reputation for quality and innovation, and they are committed to providing their customers with the best products and services possible. With the Heavy Duty Large Stackable Plastic Pallet, businesses can transport their goods safely and efficiently, while also reducing their impact on the environment.

Find Local Plastic Product Suppliers for Your Business

In recent years, the plastic product industry has seen significant growth, and with it, the demand for reliable, high-quality manufacturers. Among the top players in the market is a leading manufacturer of plastic products, with a reputation for excellent customer service and superior product quality.This manufacturer boasts years of experience in the production of plastic products, including packaging and containers for various industries. With state-of-the-art facilities and an experienced team of professionals, this company has emerged as a leading player in the plastic product industry, catering to the needs of customers across diverse sectors.The company’s product range includes a wide variety of packaging solutions, including airtight containers, pails, drums, jerry cans, and more. They also offer custom-designed packaging solutions to cater to the unique needs of their clients, ensuring that their products are packaged and delivered safely and in optimal condition.Apart from packaging solutions, the company also boasts expertise in manufacturing and delivering high-quality plastic products. With an extensive range of products in different sizes and shapes, they cater to the needs of various industries, including pharmaceuticals, food processing, agriculture, automotive, and household goods.The company’s core focus is on providing unparalleled value to its clients, by delivering top-quality products at competitive prices. Their products are designed to meet strict quality standards, and every item goes through rigorous quality checks to ensure they meet the required specifications.The company has invested in modern equipment to help them achieve their high-quality standards, including state-of-the-art injection molding machines, thermoforming machines, and extruders. Their production facilities are equipped with modern technology to help ensure that the products they deliver are of the highest quality, and they can execute orders of any size and complexity.The team behind this company is made up of highly skilled professionals who are passionate about delivering top-quality service to their clients. The company prides itself on its commitment to providing excellent customer service, and their team works closely with clients to help them identify their needs and provide the best solutions possible.Their expertise in the industry has helped them build long-term relationships with their clients, who rely on them for consistent and reliable delivery of high-quality products. They have established themselves as a trusted brand, thanks to their commitment to quality, timely delivery, and excellent customer service.Apart from their core business, the company also focuses on sustainability and environmental responsibility. They have implemented measures to reduce waste and recycle materials, reducing the environmental impact of their operations. As a socially responsible company, they are committed to ensuring that they are positively contributing to the community and environment.In conclusion, the plastic product industry is highly competitive, and for companies to emerge as trusted leaders, they must consistently deliver top-quality products and services. This leading manufacturer has achieved just that, thanks to their commitment to quality, industry expertise, and exceptional customer service. They are poised to continue their growth trajectory and maintain their position as a top player in the plastic product industry.

Easily Locate Top Plastic Manufacturers and Suppliers

Custom Plastic Manufacturer: Providing Innovative Solutions for Your Unique NeedsPlastic is an incredibly versatile material that plays an essential role in our daily lives. From packaging and medical supplies to electronics and automotive parts, plastic products are all around us. However, when it comes to finding the right plastic solution for your specific application, not all products are created equal. That's where custom plastic manufacturers come in.Custom plastic manufacturers specialize in creating high-quality, tailor-made plastic products to fit the unique needs and specifications of their clients. They utilize advanced manufacturing technology and processes to create truly custom products that can meet the most challenging requirements.One of the main benefits of working with a custom plastic manufacturer is the flexibility they offer in terms of design and materials. They can create products in any shape, size, or color, and from a wide variety of plastic materials including thermoplastics, engineering plastics, and high-performance plastics.Custom plastic manufacturers can also help their clients choose the right materials and design features to optimize the functionality, durability, and performance of their products. They can create prototypes and perform extensive testing to ensure that the final product meets or exceeds expectations.Another advantage of working with a custom plastic manufacturer is their ability to produce products with intricate details and features that standard plastic products cannot replicate. They can add textures, finishes, and even incorporate logos or other branding elements to create a unique, high-quality end product.Custom plastic manufacturers are also often used for low volume or specialty projects that traditional mass manufacturers cannot accommodate. Whether it's a one-of-a-kind product or a limited production run, custom plastic manufacturers are equipped to provide solutions for a wide range of needs.In addition to their technical expertise and capabilities, many custom plastic manufacturers also offer exceptional customer service. They work closely with their clients throughout the entire manufacturing process, from conception to delivery, to ensure that all requirements are met and that the end product satisfies their needs.If you are in need of a plastic product that cannot be bought off the shelf, consider working with a custom plastic manufacturer. By partnering with a reputable, experienced company, you can access a wide range of design and material options, as well as expertise and customer service, to create a truly personalized and effective solution for your unique needs.At (remove brand name), we are a leading custom plastic manufacturer with state-of-the-art manufacturing technology and a commitment to providing innovative solutions for our clients. Contact us today to learn more about our capabilities and to discover how we can help bring your plastic product ideas to life.

Top 5 Benefits of Using Plastic Pallets for Your Business

Title: China Emerges as a Leading Manufacturer of Plastic PalletsIntroduction:As global demand for environmentally friendly and sustainable packaging solutions continues to rise, China has emerged as a leading manufacturer of plastic pallets. With its advanced technology, cost-effective production capabilities, and continuous commitment to innovation, the Chinese plastic pallet industry is revolutionizing the global logistics and warehouse supply chain. This article will provide an overview of the current state of the plastic pallet market in China, highlighting the key players in the industry and their contributions towards sustainable packaging solutions.I. Growing Market Demand for Plastic PalletsThe increasing popularity of plastic pallets can be attributed to their durability, reusability, and recyclability. Plastic pallets offer numerous advantages over traditional wooden pallets, such as enhanced hygiene, reduced maintenance costs, and improved supply chain efficiency. As a result, the demand for plastic pallets has witnessed unprecedented growth, both domestically and internationally. This surge in demand has spurred the rapid expansion of the Chinese plastic pallet industry.II. Major Players in the Chinese Plastic Pallet MarketA. Company AOne of the leading manufacturers in China is Company A. With a strong emphasis on quality and innovation, Company A has become synonymous with sustainable packaging solutions. Their plastic pallets are manufactured utilizing high-quality raw materials and cutting-edge technology, ensuring both strength and longevity. Additionally, the company has invested heavily in research and development to create lightweight, yet durable pallets, thereby reducing transportation costs and carbon footprint.B. Company BAnother prominent player in the Chinese plastic pallet market is Company B. Recognized for its commitment to sustainability, Company B focuses on using recycled materials in its manufacturing process. By repurposing plastic waste, the company not only contributes to reducing environmental pollution but also offers cost-effective solutions to its customers. Company B's pallets are designed to withstand heavy loads while providing exceptional durability and stability.III. Environmental Benefits of Plastic PalletsThe Chinese plastic pallet industry has embraced eco-friendly practices by incorporating recycled materials and promoting sustainability throughout the entire product lifecycle. Plastic pallets are fully recyclable and can be safely incinerated without releasing harmful fumes, unlike their wooden counterparts. Furthermore, their reusability significantly reduces the demand for new pallets, resulting in a substantial reduction in deforestation and overall environmental impact.IV. Technological AdvancementsChina's plastic pallet manufacturers have been at the forefront of technological advancements in the industry. Through incorporating automation and advanced machinery, these manufacturers have increased production efficiency and optimized product quality. Additionally, technological innovations in pallet design, such as integration of RFID tracking systems and barcode identification, have significantly improved inventory management and supply chain traceability.V. Global Market ReachThe Chinese plastic pallet market has expanded its global reach, catering to the increasing demand for sustainable packaging solutions worldwide. The durable and versatile nature of plastic pallets has garnered attention from industries involved in food and pharmaceuticals, electronics, and automotive sectors. With stringent quality control measures and adherence to international shipping standards, Chinese manufacturers are well-positioned to meet the evolving needs of the global market.Conclusion:China's plastic pallet industry has grown exponentially, solidifying its position as a leading manufacturer of sustainable packaging solutions. Through continuous innovation, focus on environmental preservation, and adherence to stringent quality control measures, Chinese companies have successfully catered to the increasing demand for plastic pallets worldwide. As the world shifts towards greener packaging alternatives, the Chinese plastic pallet market is set to flourish and contribute extensively towards a more sustainable future.