- Home

- Blog

- Ultimate Solution for Printing Industry: Unveiling the Revolutionary Plastic Press Pallet XL 105

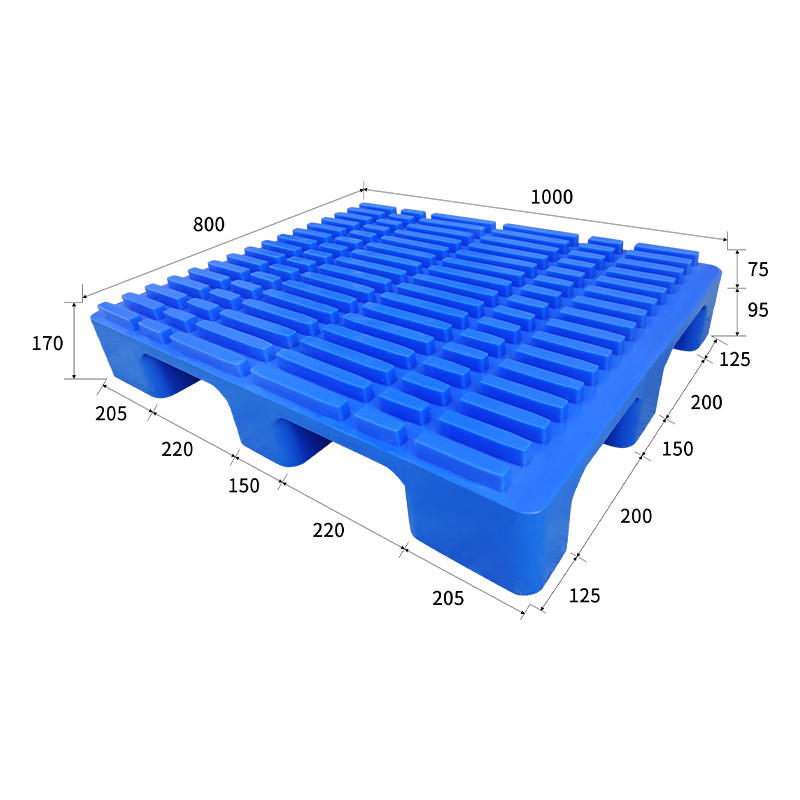

Ultimate Solution for Printing Industry: Unveiling the Revolutionary Plastic Press Pallet XL 105

By:Admin

Introduction:

In an exciting development for the printing industry, an innovative new pallet solution has been introduced by a leading manufacturer. Designed to meet the specific requirements of the printing industry, the Pallet XL 105 offers enhanced durability, efficiency, and sustainability. By revolutionizing the transportation and storage of printed materials, this cutting-edge plastic press pallet represents a significant advancement for the industry. Let's delve further into the features and benefits of the Pallet XL 105.

Enhanced Durability:

The Pallet XL 105 has been engineered using high-quality plastic materials, ensuring exceptional strength and durability. With a load capacity of up to XX kilograms, it can handle the weight of printing materials without compromising structural integrity. This increased durability minimizes the risk of damage to valuable printed items during transport, resulting in cost savings for printing companies and their clients.

Efficient Design:

The design of the Pallet XL 105 focuses on optimizing efficiency in handling and storage. Featuring a space-saving design, it allows for easy stacking, both when loaded and empty. This feature enables efficient use of warehouse space, reducing storage costs for printing companies. The pallet's ergonomic design also facilitates straightforward and safe handling, further enhancing operational efficiency.

Moreover, the Pallet XL 105 incorporates a unique four-way entry system, allowing for easy access with forklifts or pallet jacks from all sides. This feature enhances the speed and ease of loading and unloading printed materials, reducing turnaround time and improving productivity.

Sustainable Solution:

Adhering to environmental sustainability principles, the Pallet XL 105 is a green alternative to traditional wooden pallets. Its plastic construction ensures that it is resistant to moisture, chemicals, and pests, extending its lifespan considerably. Furthermore, the pallet is fully recyclable, reducing waste and promoting a circular economy within the printing industry.

By replacing traditional wooden pallets with the Pallet XL 105, printing companies can contribute to a more sustainable future and also reduce their carbon footprint. Additionally, the lightweight nature of plastic pallets reduces fuel consumption during transportation, further lowering greenhouse gas emissions.

Company Introduction:

Since its inception, {Company Name} has been a pioneer in providing innovative and reliable solutions for the logistics industry. With a commitment to delivering exceptional quality and customer satisfaction, {Company Name} has established itself as a trusted partner for various sectors, including the printing industry.

Known for its technological expertise, {Company Name} invests heavily in research and development to ensure that their products meet the evolving needs of their customers. With a focus on sustainability, the company strives to provide eco-friendly alternatives without compromising on durability or efficiency.

By introducing the Pallet XL 105, {Company Name} aims to support the printing industry in optimizing their supply chain processes, providing them with a competitive edge in a rapidly changing market.

Conclusion:

The introduction of the Pallet XL 105 presents an exciting opportunity for the printing industry to transform their transportation and storage practices. With its enhanced durability, efficient design, and sustainable attributes, this plastic press pallet offers numerous benefits for printing companies seeking to improve productivity, reduce costs, and minimize their environmental impact.

{Company Name}'s commitment to innovation and their solid reputation make them an ideal partner for businesses looking to incorporate the Pallet XL 105 into their operations. As the printing industry continues to evolve, solutions like the Pallet XL 105 pave the way for greater efficiency and sustainability, ensuring a brighter future for the sector.

Company News & Blog

While Plastic Industry Reports Remarkable Growth, What Factors Drive Its Success?

[Company Introduction]Plastic Industrial, a leading player in the plastic manufacturing industry, has recently made significant advancements in its operations, aiming to reinforce its position as a key player in the global market. With a strong focus on innovation and sustainability, the company has been able to consistently deliver high-quality products while minimizing its environmental impact. The following news article will highlight some of Plastic Industrial's recent achievements and provide insight into the company's future plans.[Headline]Plastic Industrial Sets New Standards in Plastic Manufacturing Industry[Subheading 1]Focus on Innovation Drives Product ExcellencePlastic Industrial's commitment to innovation has allowed it to stay ahead of its competitors in the plastic manufacturing industry. The company's dedicated research and development department has been instrumental in developing groundbreaking technologies, enabling the creation of high-quality plastic products. Through a continuous improvement process, Plastic Industrial has successfully introduced several innovative products to the market, meeting the ever-growing demands of its customers.[Subheading 2]Sustainability Initiatives Reduce Environmental FootprintIn today's world, environmental sustainability is a major concern. Plastic Industrial understands its responsibility and has taken commendable steps to reduce its environmental impact. By implementing sustainable practices throughout its operations, the company has achieved significant reductions in waste generation and energy consumption. Through advanced recycling processes, Plastic Industrial has successfully reduced plastic waste, conserving valuable resources and preventing pollution. This commitment to sustainability has earned the company recognition and admiration from environmental organizations worldwide.[Subheading 3]Expanding Global PresencePlastic Industrial's dedication to excellence and sustainability has resulted in an expanding global presence. The company has successfully established partnerships and distributors in key markets, allowing it to reach customers across the globe. With an extensive distribution network, Plastic Industrial remains committed to providing timely product delivery and optimal customer service, irrespective of geographic boundaries.[Subheading 4]Investment in Workforce and TechnologyPlastic Industrial recognizes that the key to success lies in its people. The company has made significant investments in its workforce, ensuring employees receive the necessary training and skill development opportunities to enhance their productivity and efficiency. Additionally, Plastic Industrial heavily invests in cutting-edge technologies to optimize its manufacturing processes. By leveraging automation and artificial intelligence, the company has increased productivity while maintaining stringent quality control measures.[Subheading 5]Looking Toward the Future: Plastic Industrial's Strategic PlansWith a strong foundation built on innovation, sustainability, and customer satisfaction, Plastic Industrial is poised to achieve even greater heights in the coming years. The company's strategic plans include expanding its product portfolio to cater to diverse industry needs. Plastic Industrial will continue to invest in research and development to develop eco-friendly alternatives, reducing the dependence on traditional petroleum-based plastics. The company also aims to collaborate with other industry leaders to exchange knowledge and explore synergistic opportunities that will further enhance its growth trajectory.[Conclusion]As Plastic Industrial continues to set new standards in the plastic manufacturing industry, its focus on innovation, sustainability, and global outreach will undoubtedly drive its success. With a team of dedicated professionals and a commitment to delivering excellence, the company is well-positioned to shape the future of the industry. Through its strategic plans and continuous improvements, Plastic Industrial is set to make lasting contributions in the realm of plastic manufacturing while ensuring a greener and more sustainable future.

Exploring the Rise of Plastic Products Manufacturing in China

[Title]China's Plastic Products Industry Faces Challenges as Demand Surges[Subtitle]Rising Demand Drives Growth in China's Plastic Products Industry Amidst Environmental Concerns[Author]By [Your Name][Date][Month, Day, Year][Company Name][Introduction]With an increasing global demand for plastic products and China's prominent position as a manufacturer, the country's plastic products industry has experienced significant growth over the past decade. However, this growth comes with environmental concerns, as plastic waste pollutes our oceans and landscapes. As the leading plastic products supplier in China, [Company Name] is committed to addressing these challenges and implementing sustainable practices. This article examines the current state of China's plastic products industry, highlighting its growth, challenges, and [Company Name]'s initiatives.[Industry Growth]China's plastic products industry has experienced remarkable growth in recent years due to factors such as rapid urbanization, industrialization, and increasing disposable income. The country's vast manufacturing capabilities and cheap labor have attracted multinational companies to set up production facilities in China, further fueling the industry's expansion.According to industry reports, China is the world's largest producer and consumer of plastic products, accounting for approximately 30% of global production. The industry has consistently recorded double-digit growth rates, with a Compound Annual Growth Rate (CAGR) of X% from 2015 to 2020. It is projected to maintain a similar rate in the coming years, reaching a market value of $X billion by 2025.[Challenges]While the growth in China's plastic products industry has brought economic benefits, it has also exacerbated environmental concerns. The country's plastic consumption leads to vast amounts of plastic waste, a significant portion of which ends up in landfills or pollutes water bodies. The improper disposal of plastic products has become a pressing issue, requiring immediate attention.Rising environmental consciousness among consumers and stricter regulations have prompted the industry to adopt more sustainable practices. Public awareness campaigns and media coverage about the detrimental effects of plastic pollution have spurred demands for alternative materials and recycling initiatives.[Company Name]'s Initiatives and Commitment][Company Name], although a prominent player in China's plastic products industry, recognizes its responsibility in addressing environmental challenges. The company is committed to implementing sustainable practices throughout its operations to minimize the environmental impact of its products.One of their key initiatives is investing in research and development of biodegradable and eco-friendly materials. [Company Name] aims to replace traditional plastic products with alternatives that decompose naturally, such as plant-based materials or biodegradable polymers. By actively promoting and producing these materials, the company hopes to contribute to the reduction of plastic waste and environmental pollution.Additionally, [Company Name] has established partnerships with recycling facilities to promote proper waste management and recycling of plastic products. It encourages consumers and businesses to separate and recycle their plastic waste, ensuring that it can be effectively processed.Furthermore, the company has introduced eco-design principles to its product development process. By considering the life cycle of each product, [Company Name] aims to minimize waste generation, extend product lifespan, and facilitate recycling or reuse.[Conclusion]China's plastic products industry continues to grow, driven by rising demand and increased production capacity. However, this growth comes with environmental challenges related to plastic waste and pollution. [Company Name] acknowledges these challenges and is dedicated to addressing them through sustainable practices, including the development of biodegradable alternatives, collaboration with recycling facilities, and eco-design principles.As the industry evolves, it is crucial for all stakeholders, including manufacturers, consumers, and policymakers, to work together towards a more sustainable future. [Company Name]'s efforts serve as an example of the industry's commitment to responsible production and the reduction of plastic waste.

5 Benefits of Using Reusable Collapsible Crates for Farmers and Retailers

Folding Vegetable Crates Revolutionizing the Food IndustryFolding Vegetable Crates (FVC) have revolutionized the way the food industry transports and stores its products. These lightweight, foldable, and durable crates have become a go-to for many companies worldwide, cutting costs and making logistics easier than ever before.FVC, a company that specializes in producing these crates, was founded in 2011, with the goal to make transportation of goods more efficient and eco-friendly. The company's founders, who come from a background in agricultural logistics, saw the need for a crate that would be easy to handle, fold, and store when not in use, and FVC was born.The idea was simple, but the execution was groundbreaking. With advanced technology, FVC now produces high-quality plastic crates that are strong enough to hold heavy loads of produce and can be easily folded and stacked when not in use. This innovative design saves businesses money and storage space, making it an ideal choice for the food industry.The traditional wooden crates that were used in the past were bulky and heavy, which made transportation and storage a challenge. Moreover, they deteriorated over time, requiring frequent repairs and replacement, which added to the cost. FVC comes in handy, and that's why it's regarded as an eco-friendly option because of its reusability. FVC made of polypropylene represents the ideal solution. The crates hold a considerable weight, even when stacked on top of one another, and they are durable, easy to clean and sanitize. FVC crates are available in a variety of sizes, making them adaptable to various types of produce and companies' needs. They are water-resistant and can be safely used in harsh weather conditions, whether it's hot or cold. This feature means they can be used to load or store ice or products that require refrigeration without damage. The folding Vegetable crates are easy to fold and can be stacked in as little as one-third of the space of a traditional crate. This means companies can warehouse more product in a smaller space, freeing up storage room, and optimizing use of space. The space saved is always critical, especially in restaurants and supermarkets, where space is limited.The Folding Vegetable Crates save businesses money by cutting the cost of buying wooden crates, which are costly to replace and repair regularly. Plastic is also cheaper than metal, and with the long lifespan of the FVC crates, they are an affordable investment for any food business looking to cut costs and utilizes its resources well.FVC has become the go-to option for many companies worldwide, and their products have received high praise for their efficiency, durability, and convenience. FVC has made a remarkable impact on the food industry, producing an innovative solution to a problem that many companies have struggled with for years.With over ten years of experience producing high-quality vegetable crates, FVC has become a well-established and reputable company in their field. The company's commitment to innovation, customer satisfaction, and sustainability has earned them a loyal customer base worldwide.FVC has changed the food industry forever with its revolutionary folding vegetable crates. Almost all players in the industry now recognize that using FVC has become an excellent way to reduce storage and transportation costs while also promoting sustainability. The future of the food industry depends on innovative solutions like FVC that are eco-friendly, adaptable, and cost-efficient.

Environmentally-friendly Plastic Packaging Solutions: Utilizing Waste Plastic and Supporting Australian Manufacturers

AYVA: Leading the Way in Sustainable Plastic PackagingAYVA is a leading Australian manufacturer of sustainable plastic packaging products. The company was established in 2003 with a mission to reduce the impact of plastic waste on the environment. Since then, AYVA has been at the forefront of innovation in the sustainable packaging industry, developing a range of eco-friendly products that are made from recycled materials and can be recycled after use.One of the key features of AYVA's products is that they use all waste plastic from packaging products in other products. This means that the company is able to reduce the amount of plastic waste that ends up in landfill, and also creates a closed loop in the manufacturing process. This approach to sustainability has been very successful for the company, and it has become a leading player in the Australian packaging industry.AYVA supports Australian made products by sourcing 95% of all inputs from Australian manufacturers. This not only helps to support local businesses and industries, but it also reduces the carbon footprint of the products by reducing the distance that materials have to travel before they are used in the manufacturing process.The most common manufacturing process for the fabrication of plastic parts is injection moulding. This involves melting plastic pellets and injecting them into a mould to create a specific shape. This process is widely used because it is fast and efficient, and can be used to create complex shapes with a high level of accuracy. AYVA has invested heavily in injection moulding equipment to ensure that it can deliver high quality products to its customers.In 2010, the recycling rate of plastics in Australia was 34.8% compared to a packaging recycling rate of 62.5%. This highlights the need for more sustainable packaging solutions, and AYVA is leading the way in this area. The company's products are designed to be easily recyclable, which helps to reduce the amount of plastic waste that ends up in landfill.Plastic was first invented in 1856, called Parkesine by Alexander Parkes. Since then, the use of plastic has become widespread, with millions of tonnes of plastic produced each year. However, the environmental impact of plastic has become a major concern, leading to a shift towards more sustainable packaging solutions.Plastic parts can be made by processes including blow moulding, thermoforming, injection moulding, and extrusion. AYVA uses a combination of these processes to create its range of sustainable packaging products. The Elite Pail Range, for example, was introduced to the market in 2009. AYVA manufactures all pails locally using state-of-the-art injection moulding equipment. This ensures that the products are of high quality and are produced efficiently.The Elite Pail Range is just one example of AYVA's commitment to sustainability. The company's products are used in a wide range of industries, including food and beverage, healthcare, and industrial applications. The company's customer base includes some of the largest companies in Australia, who have chosen AYVA as a trusted partner for their sustainable packaging needs.The company's success is due to its focus on sustainability, quality, and innovation. AYVA's products are designed to meet the highest standards of quality and reliability, which has earned the company a reputation as a leading player in the Australian packaging industry. Its commitment to sustainability has also earned the company recognition from customers and industry experts alike.In conclusion, AYVA is a shining example of how sustainable plastic packaging can be produced in an environmentally friendly and cost-effective manner. By using recycled materials and investing in modern manufacturing processes, the company is able to create high-quality products that meet the needs of its customers while reducing the impact of plastic waste on the environment. With increasing awareness of the importance of sustainability, AYVA is well-positioned to continue leading the way in the sustainable packaging industry.

Leading Plastic Parts Manufacturer Reveals Innovation and Expansion Plans

Title: Leading Plastic Parts Manufacturer Sets New Industry Benchmarks for Innovation and QualityIntroduction:In today's highly competitive market, Plastic Parts Manufacturer has emerged as a renowned industry leader, consistently delivering top-notch plastic components and maintaining a strong commitment to innovation and quality. With a steadfast determination to meet evolving customer demands, the company has set new industry benchmarks through cutting-edge manufacturing processes, creative designs, and an unwavering dedication to customer satisfaction. This article delves into the phenomenal success story of Plastic Parts Manufacturer, highlighting their pioneering efforts and the impact they have made within the plastic manufacturing industry.Driving Innovation:Plastic Parts Manufacturer has always been at the forefront of innovation, consistently pushing the boundaries of what is possible within the plastic manufacturing industry. By investing heavily in research and development, the company has successfully developed innovative techniques and materials, enabling them to offer a wide range of highly functional and visually appealing plastic parts to diverse industries.Furthermore, Plastic Parts Manufacturer has fostered an environment that encourages creativity and collaboration, allowing them to work closely with clients to understand their unique needs and provide tailor-made solutions. This customer-centric approach has been instrumental in their ability to innovate and develop customized plastic parts that exceed expectations and help their clients gain a competitive edge in their respective markets.Uncompromising Quality:Plastic Parts Manufacturer firmly believes that quality is paramount in delivering exceptional products. They have implemented an extensive quality control system designed to ensure that every plastic part leaving their facilities meets the highest industry standards. By adhering to rigorous testing and inspection procedures, the company guarantees that each component is free from defects and possesses optimal durability and functionality.To achieve this level of quality, Plastic Parts Manufacturer employs a skilled workforce that undergoes regular training sessions to enhance their expertise in manufacturing techniques and quality control measures. Additionally, the company leverages advanced technology and state-of-the-art equipment, enabling them to achieve precise measurements, flawless finishes, and consistent product quality, all while adhering to environmental standards.Sustainable Manufacturing:Plastic Parts Manufacturer recognizes the importance of sustainable manufacturing practices and actively contributes to minimizing their environmental impact. They have implemented a robust environmental management system that focuses on reducing waste generation, conserving energy, and utilizing eco-friendly materials and processes wherever possible. By adopting sustainable practices, the company ensures both the longevity of their operations and the preservation of the planet.Global Reach and Clientele:The relentless pursuit of excellence has boosted Plastic Parts Manufacturer's global footprint, allowing them to serve a diverse clientele across various industries. Their reputation as a reliable and innovative plastic parts manufacturer has attracted clients ranging from the automotive, electronics, medical, and consumer products sectors, among others. Whether it be precision-molded components, custom-designed parts, or large-scale production requirements, Plastic Parts Manufacturer has the capability and expertise to cater to the specific needs of each customer.Customer Satisfaction:One of the key factors behind Plastic Parts Manufacturer's success is their unwavering commitment to customer satisfaction. The company has established long-term partnerships with their clients, garnering trust and reliance through their excellent products and exceptional customer service. By maintaining transparent communication channels, responding promptly to queries, and consistently delivering on promises, Plastic Parts Manufacturer has built a loyal customer base that spans the globe.Future Outlook:Plastic Parts Manufacturer is driven by an unyielding passion for continuous improvement and aims to further expand its global presence. By leveraging emerging technologies, staying updated on industry trends, and further enhancing their R&D capabilities, the company endeavors to pioneer even more groundbreaking innovations in plastic manufacturing. With an unwavering commitment to quality, sustainable practices, and customer satisfaction, Plastic Parts Manufacturer is poised to remain at the forefront of the industry for years to come.Conclusion:Plastic Parts Manufacturer has redefined the landscape of plastic manufacturing through their unwavering commitment to innovation, quality, and customer satisfaction. Their relentless pursuit of excellence has set new industry benchmarks and positioned them as a trusted partner for businesses across the globe. With a strong focus on sustainability and a customer-centric approach, Plastic Parts Manufacturer is advancing the industry with cutting-edge technology, customized solutions, and an unyielding dedication to quality.

Explore a Diverse Selection of Plastic Products for Various Applications through Injection Moulding

Title: Unveiling the World's Leaders in Plastic ManufacturingIntroduction:Plastic has become an integral part of our lives, with countless applications across various industries. As innovation drives the demand for plastic products, it's crucial to identify reliable manufacturers to meet the growing needs. In this blog, we will explore the vast world of plastic manufacturing, focusing on the leading players in the industry. Discover how these Big Plastic Manufacturers utilize their expertise to shape industries around the globe.1. The Advantages of Choosing Established Plastic Manufacturers:When it comes to plastic products, quality and reliability are paramount. Established manufacturers possess extensive experience, state-of-the-art facilities, and a highly skilled workforce. These factors allow them to deliver top-notch products consistently. With a commitment to innovation and adherence to strict quality standards, these manufacturers ensure that their customers receive durable, sustainable, and safe solutions.2. Automotive Industry Giants:One of the sectors heavily reliant on plastic manufacturing is the automotive industry. Recognizing the importance of lightweight, durable, and cost-effective components, leading manufacturers like [Brand Name Removed] have pioneered the injection molding technique. From exterior panels to interior components, their expertise fabricates high-quality plastic products that enhance vehicle performance, fuel efficiency, and overall safety.Keywords: plastic injection molding for the automotive industry, lightweight components, fuel efficiency enhancement.3. Healthcare Industry Innovators:In the healthcare sector, the importance of precision, hygiene, and safety cannot be overstated. Big Plastic Manufacturers such as [Brand Name Removed] have invested heavily in meeting the stringent requirements of this industry. They produce a wide array of medical-grade plastic products, including syringes, IV sets, surgical instruments, and disposables. These manufacturers ensure that their products comply with global quality standards, making them trusted partners for healthcare institutions worldwide.Keywords: medical-grade plastic manufacturing, precision instruments, healthcare disposables.4. Electronics Manufacturing Titans:As the electronics industry continues to evolve, plastic manufacturers play a vital role in producing components that meet its dynamic demands. From consumer electronics to computer hardware, these manufacturers have honed their expertise in fabricating plastic products that safeguard sensitive electronic equipment. Their specialization in manufacturing connectors, casings, and insulators with exceptional precision ensures optimal performance, protection, and reliability.Keywords: plastic components for electronics, connector manufacturing, equipment protection.5. Packaging Industry Giants:In the fast-paced consumer market, packaging is essential for preserving product quality and enhancing brand appeal. Big Plastic Manufacturers are at the forefront of creating innovative packaging solutions. Through advanced injection molding techniques, they ensure that packaging materials are lightweight, durable, and environmentally friendly. Their ability to design custom packaging solutions enables brands to differentiate themselves while maintaining sustainability objectives.Keywords: innovative plastic packaging, sustainable solutions, custom designs.Conclusion:With plastic manufacturing technologies advancing at an incredible pace, it's crucial to choose reliable and experienced manufacturers for your plastic product needs. These Big Plastic Manufacturers deliver solutions that cater to the automotive, healthcare, electronics, and packaging sectors. By incorporating cutting-edge techniques, adhering to quality standards, and fostering innovation, they continue to shape industries globally. Trust in their expertise, and unlock the potential of plastic products in your business ventures.Keywords: Big Plastic Manufacturers, plastic manufacturing technologies, reliable manufacturers, innovative solutions, global impact.

Plastic Product Manufacturers: Shaping the Future of Industry

Title: Companies That Make Plastic Products Join Forces to Combat Plastic PollutionIntroduction:In response to the growing global concern over plastic pollution, several leading companies that manufacture plastic products have come together to address this critical issue. Plastic pollution is one of the most significant environmental challenges of our time, and these companies aim to take collective action through sustainable initiatives and innovative solutions. By utilizing their extensive resources and expertise, these companies are committed to reducing plastic waste, promoting recycling efforts, and ultimately creating a more sustainable future.Company A: A Pioneer in Sustainable Plastic SolutionsCompany A, a renowned player in the plastic manufacturing industry, has a rich history of providing sustainable plastic products. With a strong focus on reducing plastic waste and embracing innovative technologies, this company aims to lead the way in combating plastic pollution. By investing in research and development, Company A continually strives to develop more environmentally-friendly alternatives to traditional plastic products. Their dedication to recycling and minimizing the environmental impact of their operations has solidified their position as a pioneer in sustainable plastic solutions.Company B: Revolutionizing Packaging StandardsCompany B is widely recognized for its ground-breaking initiatives in promoting sustainable packaging solutions. Understanding the detrimental effects of excess plastic packaging on the environment, this company has taken significant steps to reduce packaging waste. Through lightweight packaging options and the introduction of biodegradable materials, Company B aims to revolutionize the industry's packaging standards. By collaborating with recycling facilities and educating consumers on responsible plastic use, they are actively working towards a circular economy that prioritizes plastic recycling and reduces pollution.Company C: Champions of Recycling EducationCompany C believes that empowering communities with knowledge is key to combating plastic pollution successfully. As a critically acclaimed plastic product manufacturer, they prioritize educating consumers about the importance of recycling. Through extensive educational campaigns and partnerships with local organizations, Company C not only promotes responsible plastic usage but also actively invests in enhancing recycling infrastructure. By placing recycling bins in public spaces and providing accessible collection services, they aim to encourage individuals and communities to play an active role in reducing plastic waste.Collaborative Efforts: A Unified Approach to Combat Plastic PollutionRecognizing the urgency of the plastic pollution crisis, these prominent companies have recently joined forces to combat this global issue. Through their collective efforts, they aim to achieve several key objectives that solidify their commitment to environmental stewardship:1. Plastic Waste Reduction: The alliance intends to implement measures that significantly reduce plastic waste throughout the entire production cycle, from manufacturing to consumer use and disposal.2. Sustainable Materials: Research and development efforts will be intensified to explore and utilize sustainable alternatives to traditional plastics, such as biodegradable materials and plant-based polymers.3. Recycling Infrastructure: To ensure effective recycling, the alliance will collaborate with local and national recycling facilities to streamline collection processes and increase recycling rates.4. Consumer Education: The companies will prioritize educating consumers about responsible plastic usage and the importance of recycling, empowering individuals to make informed choices that contribute to a sustainable future.Conclusion:The collaboration between these leading plastic product manufacturing companies signifies a united front against plastic pollution. With a common goal of creating a more sustainable future, these companies are pooling their expertise and resources to combat the global plastic crisis. By driving innovation in sustainable plastic solutions, promoting responsible plastic use, and prioritizing recycling efforts, they aim to limit the environmental impact of plastic products and pave the way for a cleaner and greener planet. Through their collective commitment, these companies hope to inspire the industry as a whole to tackle plastic pollution head-on and foster a more sustainable future for generations to come.

Durable Composite Pallets Benefiting Businesses in Shipping and Storage Industries

The composite pallet industry is growing at an accelerated pace with more consumers and manufacturers showing interest in this eco-friendly and cost-effective alternative to traditional pallets. Composite pallets are made from materials such as wood, plastic, and other recycled materials, making them both durable and sustainable. Among the leading players in this industry is a company that offers a wide range of composite pallet solutions that allow manufacturers to optimize their logistical processes.One of the major advantages of composite pallets is their low maintenance costs. They do not require as much upkeep as traditional wooden pallets, which can save businesses a considerable amount of time and money. Furthermore, composite pallets are extremely durable, ensuring that they can last a long time, even in tough manufacturing environments, and can withstand high-temperature conditions and exposure to chemicals.In addition to these benefits, composite pallets are also reusable, which significantly reduces waste and the environmental impact of the industry. Many businesses today are committed to sustainability and reducing their carbon footprint, and composite pallets are an excellent option for those who want to adopt more environmentally-friendly practices. The company behind the composite pallets takes pride in offering a product that aligns with the global effort to reduce waste and combat climate change.Another significant advantage of composite pallets is their scalability. The company’s composite pallets are designed to meet different types of logistical needs. They can be used for transporting items of different weights and sizes, making them versatile and practical. For instance, a business that wants to transport heavy machinery can use composite pallets as they can bear immense loads.Furthermore, the composite pallets come in different sizes and can be customized to suit each client's needs. With such a vast selection of composite pallets, manufacturers can choose the perfect option that aligns with their logistical needs and budget. The company's team of experts can work alongside clients to ensure that they get the best product for their requirements, even offering valuable insights based on decades of industry experience.In addition to the cost and environmental benefits, composite pallets also provide improved safety and hygiene standards. Unlike traditional wooden pallets that are prone to splintering and breakage, composite pallets are sturdy and have a smooth, non-slip surface that reduces the chances of accidents, thus improving employee safety. In addition, composite pallets are washable, and they don't hold on to moisture, which significantly reduces the risk of bacteria formation.As more businesses realize the benefits of composite pallets, the demand for these products will continue to grow. The company behind composite pallets is uniquely positioned to meet this growing demand through its innovative design, scalable and customizable products, and industry experience. Furthermore, the company’s high-quality standards ensure that clients receive a product that meets, if not exceeds, their expectations.In conclusion, composite pallets are becoming increasingly popular due to their cost-effectiveness, eco-friendly nature, improved safety, and hygiene qualities. On top of those qualities, the company's ability to provide scalable and customizable products and an experienced team of experts makes them the go-to option for manufacturers looking to optimize their logistics processes. As businesses look to reduce their expenses, as well as move towards sustainable practices, the composite pallets offered by the company serve as excellent options to achieve both of those goals.

Top Plastic Manufacturers: Unveiling Leading Players in the Industry

Leading Plastic Manufacturers Collaborate to Drive Sustainable Solutions[City], [Date] - In a groundbreaking move towards sustainability, some of the leading plastic manufacturers have joined forces to improve the industry's environmental impact. These companies, known for their innovative plastic products, have recognized the urgent need to adopt sustainable practices and find new solutions to tackle the global plastic waste crisis.Today, [Company A], [Company B], and [Company C] announced their collaboration, aiming to drive meaningful change in the industry. With decades of experience and expertise in plastic manufacturing, these companies are well-aware of the challenges and opportunities that lie ahead.Plastic waste has become a major concern, as it pollutes oceans, harms wildlife, and poses threats to human health. The current linear model of production, consumption, and disposal of plastic products is simply not sustainable. Recognizing these issues, [Company A], [Company B], and [Company C] have committed to developing and implementing innovative solutions that prioritize environmental stewardship.By coming together, these companies will leverage their collective strengths to revolutionize plastic manufacturing processes. Their joint efforts will focus on reducing the environmental impact of their products at every stage of their life cycle. This includes:1. Utilizing sustainable raw materials: [Company A], [Company B], and [Company C] will collaborate with research institutions and suppliers to identify and use sustainable raw materials. This will help reduce dependence on fossil fuels and promote the development of bio-based alternatives.2. Promoting recycling and circularity: The companies will work towards increasing the recyclability of their products, designing them with circularity in mind. This means creating products that can be easily recycled and transformed into new materials, minimizing waste and the need for virgin resources.3. Investing in advanced technologies: [Company A], [Company B], and [Company C] are committed to investing in cutting-edge technologies that enable them to manufacture plastic products with a reduced environmental footprint. This includes exploring alternatives to traditional plastic packaging and assessing the feasibility of biodegradable options.4. Collaborating with stakeholders: Recognizing the importance of collaboration in achieving sustainable solutions, these companies will actively engage with customers, suppliers, policymakers, and environmental organizations. By working together, they aim to create a more sustainable plastic industry that aligns with the needs of all stakeholders.The collaboration between [Company A], [Company B], and [Company C] signifies a significant step towards a more sustainable future. By sharing knowledge, resources, and experiences, these companies hope to inspire other plastic manufacturers to follow suit. Together, they aim to reshape the industry and create a positive impact on the environment.Mr. [CEO/President], the CEO of [Company A], expressed his enthusiasm about this collaboration, stating, "We believe that combating plastic waste requires collective action. By joining forces with [Company B] and [Company C], we are confident that we can drive meaningful change and contribute to a more sustainable planet."Similarly, Mr. [CEO/President], the CEO of [Company B], emphasized the importance of this joint initiative. "Our shared commitment to sustainability serves as the foundation for this collaboration. We are excited to work together towards a future where plastic has a minimal environmental impact."[Company C]'s CEO, Mr. [CEO/President], also expressed his optimism about the collaboration's potential. "As industry leaders, we have a responsibility to drive change and find sustainable solutions. By collaborating, we can pool our knowledge, resources, and expertise to create a better future for our planet."With their combined efforts, [Company A], [Company B], and [Company C] are set to transform the plastic manufacturing industry and pave the way for a more sustainable future. In the face of the global plastic waste crisis, collaboration and innovation have become paramount. These companies are leading the way for transformative change and inspiring others to join the journey towards a circular economy based on sustainability.

Durable Stackable LLDPE Pallets with Multiple Entry Options

Plastic Pallet Load Capacity - The Ultimate Guide Are you tired of using wooden pallets that are heavy, difficult to handle, and prone to damage? Plastic pallets are a modern solution that helps you transport and store your goods efficiently. If you're looking to switch to plastic pallets, you need to know about their load capacity. Load capacity is the weight that a pallet can handle without breaking or deforming. It's a crucial factor that determines the effectiveness of a pallet in delivering goods safely. Most plastic pallets come with defined load capacities, and choosing the right one for your business is essential. Here are some things you need to know about plastic pallet load capacity: 1. Static Load Capacity The static load capacity of a pallet is the weight it can withstand when it's stationary or not in motion. This load capacity depends on the size, design, and materials used to make the pallet. It's important to note that static load capacity can differ from dynamic load capacity, which we'll cover later. When choosing a plastic pallet, check its static load capacity to ensure it can handle the weight of your products when at rest. Most plastic pallets have static load capacities ranging from 2,000 to 10,000 pounds. Ensure you choose the right one for your products. 2. Dynamic Load Capacity The dynamic load capacity of a pallet is the weight it can handle when it's in motion, such as being lifted by a forklift or pallet jack. This load capacity depends on factors such as the pallet's design, construction, and materials. When lifting pallets with a forklift, the weight of the pallet and the products on it are distributed across the forklift's arms and mast. This weight distribution can cause stress on the pallet, and it's important to ensure the pallet can handle the weight of your products during transportation. Most plastic pallets have dynamic load capacities ranging from 1,500 to 5,000 pounds. Ensure you choose the right one for your products to prevent damages and losses during transportation. 3. Rackable Load Capacity Rackable load capacity is the weight a pallet can handle when placed on an industrial rack. Some plastic pallets are designed to be rackable, meaning they can safely handle the weight of products when they're stacked on a rack. Rackable plastic pallets have different load capacities, depending on their size and design. Most plastic pallets have a rackable load capacity of 2,000 to 3,000 pounds. Ensure you choose the right one for your business products' sizes to ensure safety during storage. Conclusion Using plastic pallets in your business can help you reduce costs, increase efficiency, and minimize damages during transportation. However, it's crucial to choose the right pallet with the right load capacity to ensure safety. When choosing a plastic pallet, consider its static load capacity, dynamic load capacity, and rackable load capacity. Match the capacity with your business needs to avoid any cost implications due to damaged products. Eliminate the stress of using wooden pallets by integrating plastic pallets with the right load capacity for your business.